Exploitation measuring device and method of coal bed gas well

A measurement device and coalbed methane well technology, which is applied in the directions of measurement, mining fluid, earthwork drilling, etc., can solve the problems of large area, misjudgment of the production status of coalbed methane wells, and increased equipment costs, so as to improve the upper limit of measurement and simplify the ground equipment, cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with example the present invention is described in detail.

[0052] The present invention can be applied not only to coal bed gas well site, but also to oil and gas well site measurement and control. The application conditions are similar and will not be described one by one here.

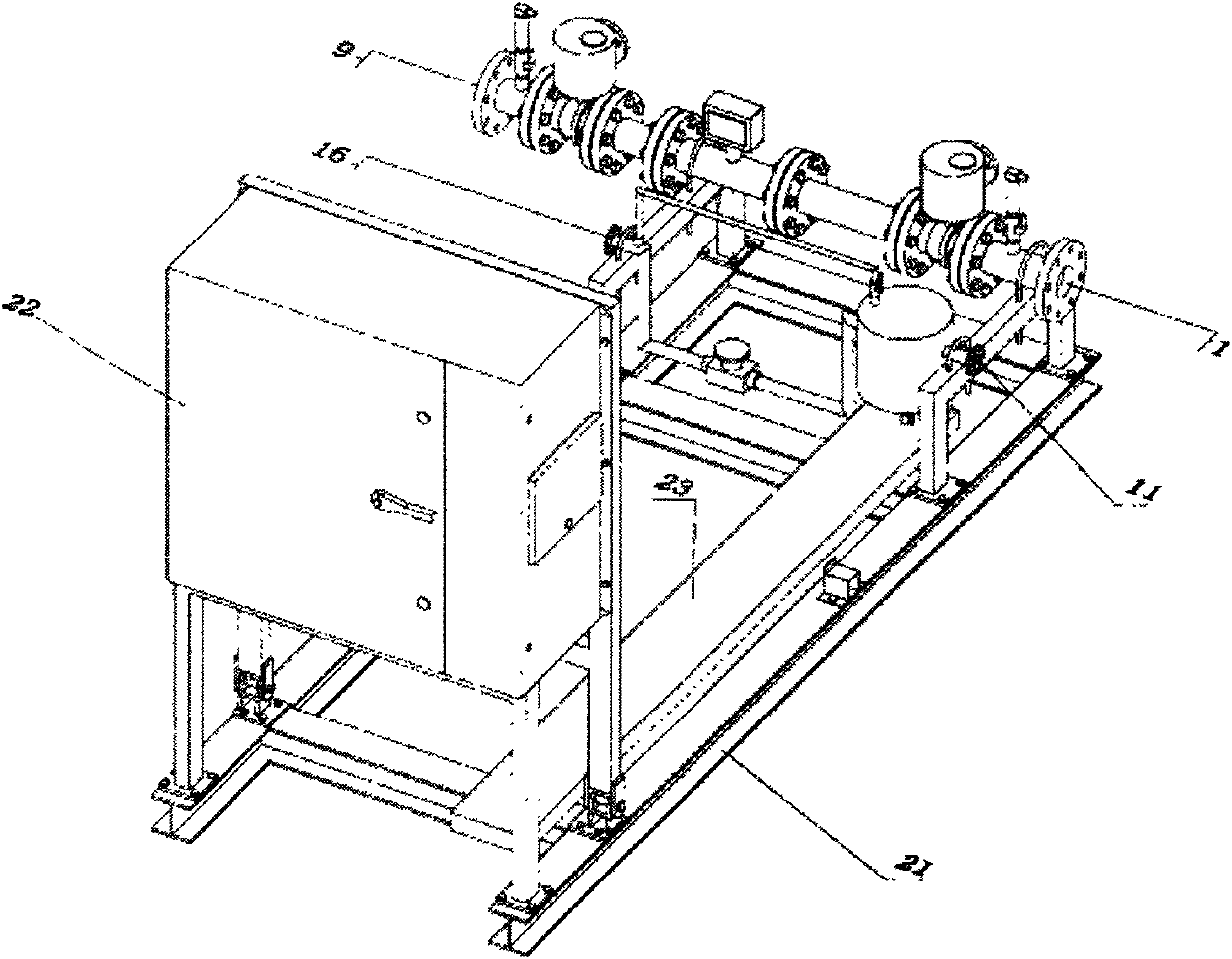

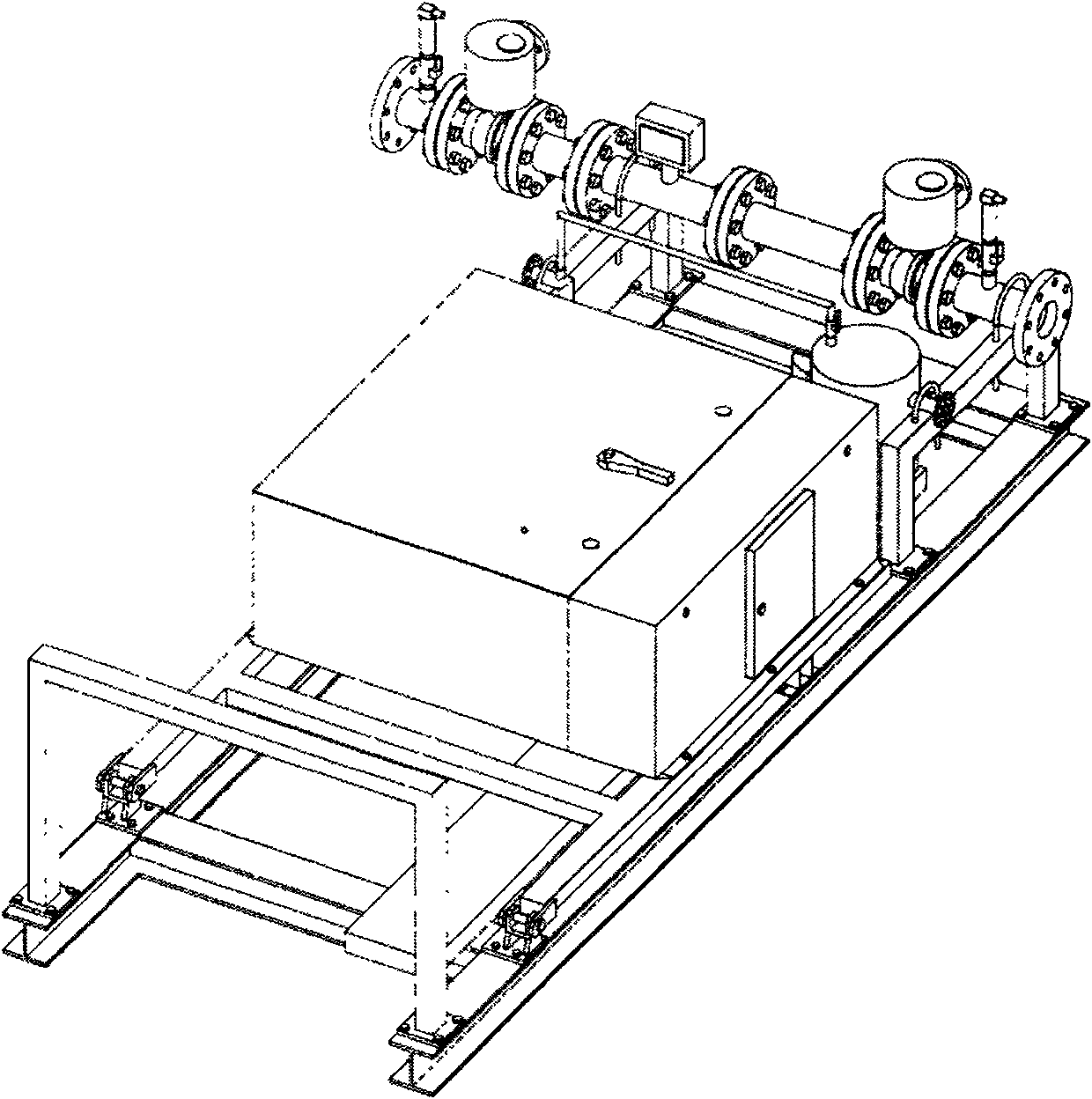

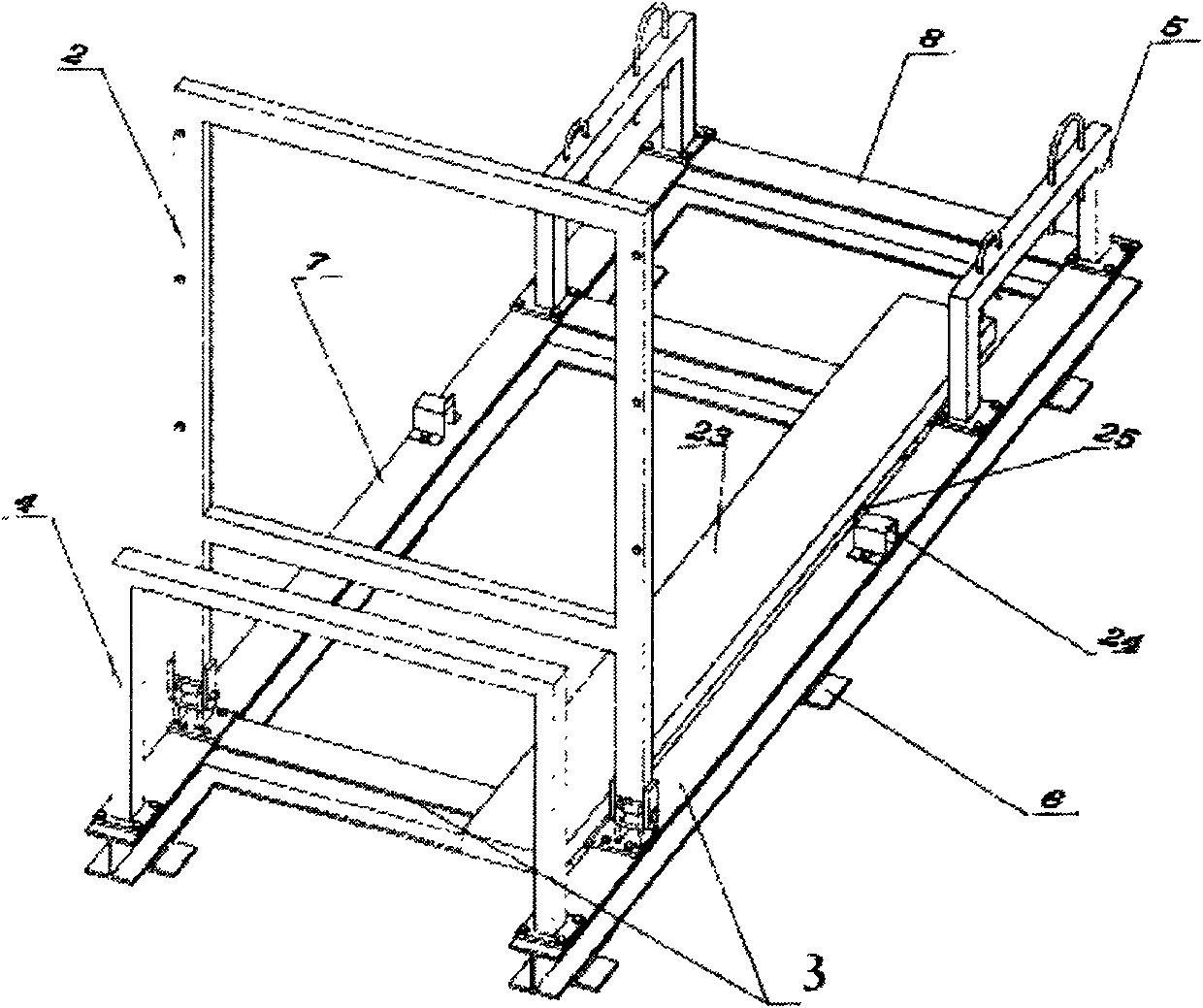

[0053] like figure 1 and figure 2 As shown, the coalbed methane well drainage measurement system of the present invention includes a base support 21, a production fluid measurement device, a produced gas measurement device and a control system. The produced liquid measuring device and the produced gas measuring device are installed at one end of the base support 21 , and the control system control box is installed at the other end of the base support 21 . The present invention integrates existing control devices such as various collection and measurement control devices and electrical equipment (such as frequency converters, dynamic electric parameter collectors and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com