High-strength solidifying agent for sludge solidified soil and preparation method thereof

A technology of solidifying soil and solidifying agent, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc. The effect of rapid increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

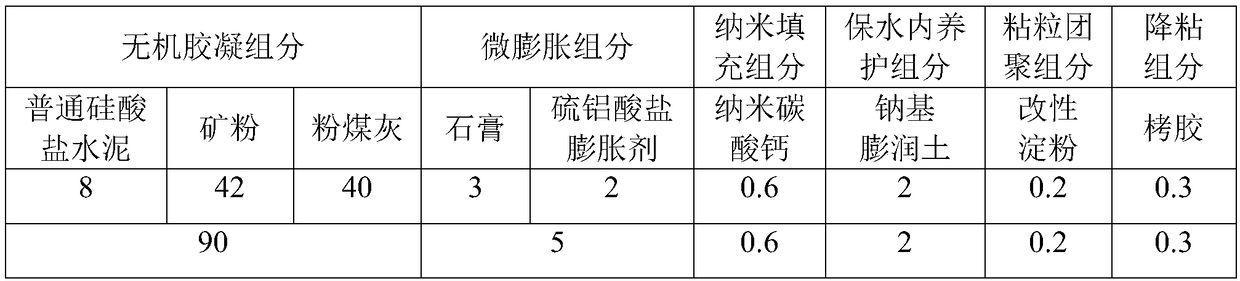

[0047] In the present embodiment, the solidifying agent for high-strength silt solidified soil is composed as Table 1. The prepared solidifying agent is used to solidify the silt. The moisture content of the silt is 45%. Every cubic silt is mixed with 150kg of this curing agent and stirred evenly, and the prepared silt is solidified. The mechanical properties of soil at 7 days and 28 days age are shown in Table 2.

[0048] Table 1 Weight composition of curing agent for high-strength silt-solidified soil (unit: part)

[0049]

[0050] Table 2 Mechanical properties of prepared silt-solidified soil at 7 days and 28 days age

[0051] age

Embodiment 2

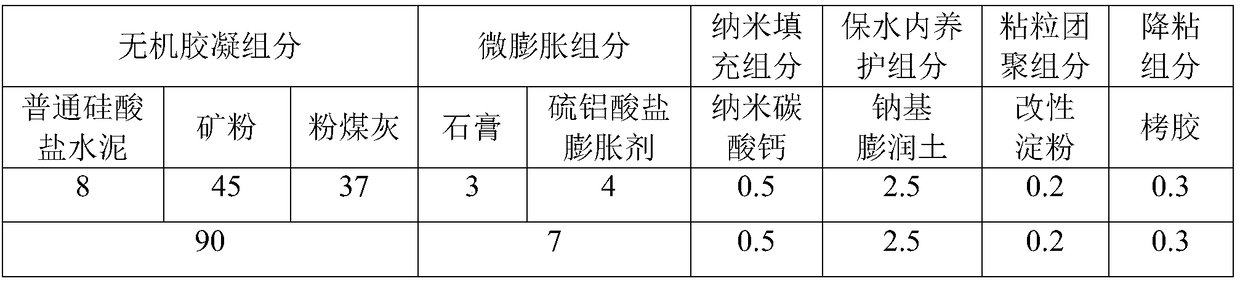

[0053] In the present embodiment, the solidifying agent composition for high-strength silt solidified soil is as shown in Table 3. The prepared solidifying agent is used to solidify the silt. The moisture content of the silt is 50%. Every cubic silt is mixed with 150kg of this curing agent and stirred evenly, and the prepared silt is solidified. The mechanical properties of soil at 7 days and 28 days age are shown in Table 4.

[0054] Table 3 Weight composition of curing agent for high-strength silt-solidified soil (unit: part)

[0055]

[0056] Table 4 Mechanical properties of prepared silt-solidified soil at 7 days and 28 days age

[0057] age

Embodiment 3

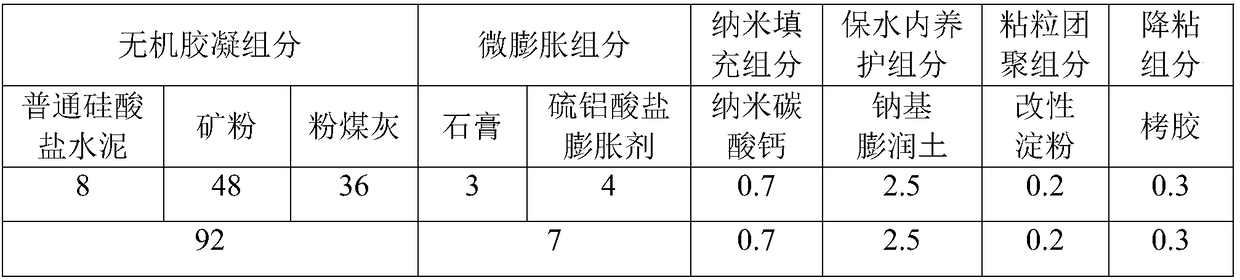

[0059] In this embodiment, the solidifying agent for high-strength silt solidified soil is composed as Table 5. The prepared solidifying agent is used to solidify the silt. The moisture content of the silt is 56%. Every cubic silt is mixed with 160kg of this curing agent and stirred evenly, and the prepared silt is solidified. The mechanical properties of soil at 7 days and 28 days age are shown in Table 6.

[0060] Table 5 Weight composition of curing agent for high-strength silt-solidified soil (unit: part)

[0061]

[0062] Table 6 Mechanical properties of prepared silt-solidified soil at 7 days and 28 days age

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com