OLED device and encapsulation method and display device thereof

A packaging method and device technology, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device manufacturing, etc., can solve problems such as cracks and damages, achieve moderate pressure difference inside and outside the box, ensure sealing protection, improve Bad effect of cracks and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

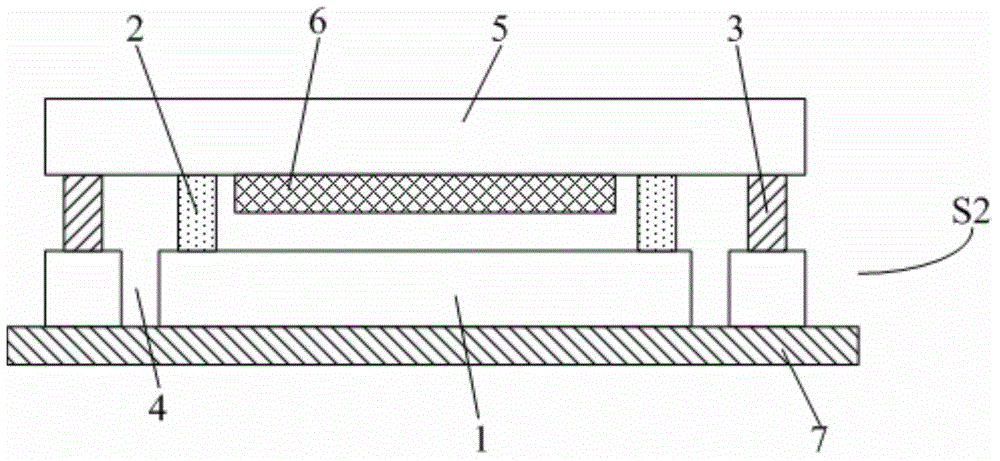

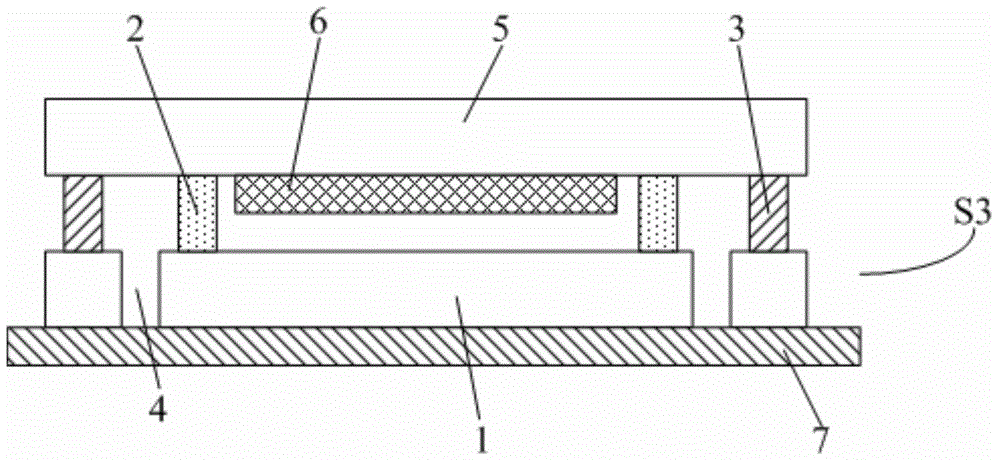

[0043] This embodiment provides a packaging method for an OLED device, such as Figure 1-Figure 8 shown, including:

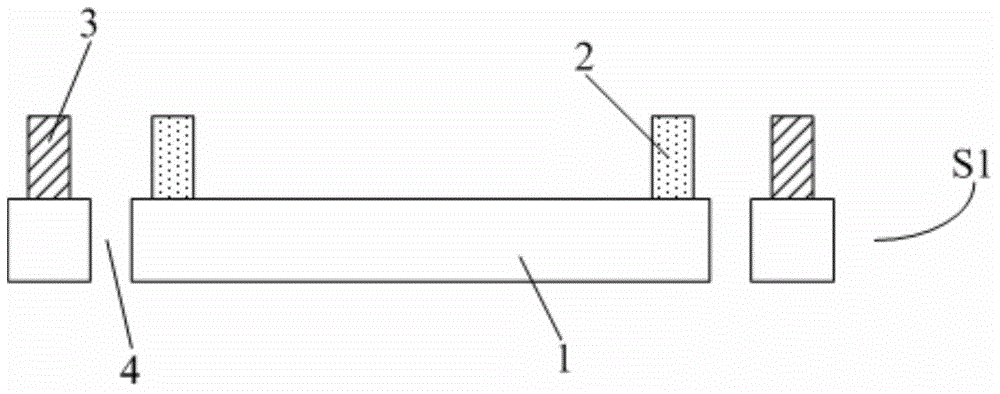

[0044] Step S1: Open a through hole 4 on the cover plate 1 between the area for forming the glass glue 2 and the area for coating the UV glue 3, and form the glass glue 2 and the UV glue 3 on the same surface of the cover plate 1. Coating UV glue 3, UV glue 3 is coated on the periphery of glass glue 2 (as figure 1 ).

[0045] The through holes 4 opened in this step include a plurality of through holes 4 evenly distributed in the area between the UV glue 3 and the glass glue 2 . The provision of a plurality of through holes 4 is beneficial to make the pressure in the box formed by the cover plate 1 and the back plate 5 to reach the second pressure quickly in the subsequent step S5. Wherein, the width of the distribution area of the through holes 4 is less than 1mm. The diameter of the through hole 4 is in the range of 0.1-0.2mm. The width and diameter of ...

Embodiment 2

[0064] This embodiment provides an OLED device, which is packaged using the packaging method in Embodiment 1.

[0065] The OLED device is packaged by using the packaging method in Example 1, which improves the defect that the glass glue used for OLED device packaging is easily squeezed to cause cracks and damage under the action of the pressure difference between the box and the outside of the box, thereby improving the OLED device. encapsulation effect.

Embodiment 3

[0067] This embodiment provides a display device, including the OLED device in Embodiment 2.

[0068] By adopting the OLED device in Embodiment 2, not only the encapsulation effect of the display device is improved, but also the encapsulation quality of the display device is improved.

[0069] The display device provided by the present invention can be any product or component with OLED display function, such as OLED panel, OLED TV, OLED display, OLED mobile phone, OLED navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com