Floor split joint ventilating pipe structure and ventilating structure

A technology for ventilation pipes and floor slabs, which is applied to floors, vertical pipes, building components, etc. It can solve the problems of affecting the appearance of buildings and affecting indoor net heights, and achieves the effects of low cost, convenient disassembly, and improvement of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

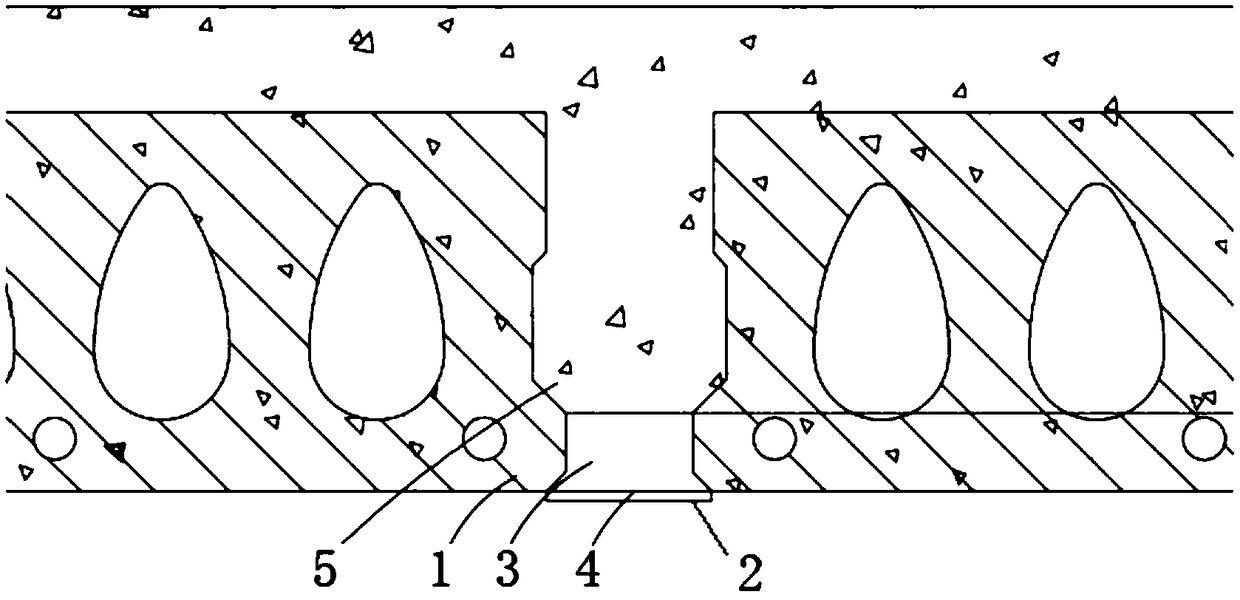

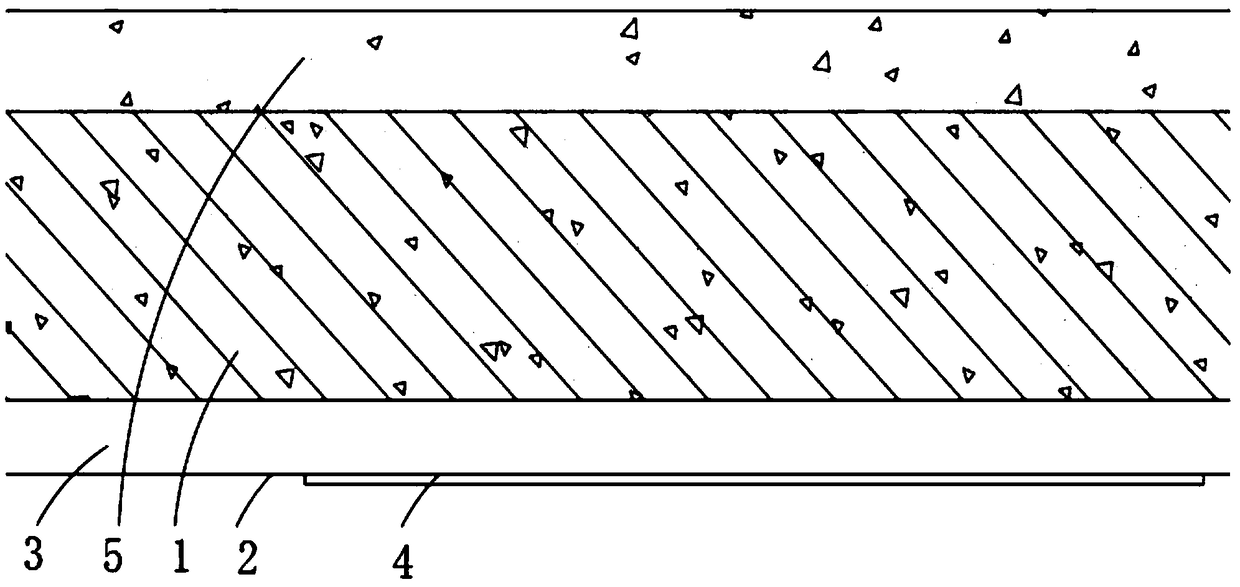

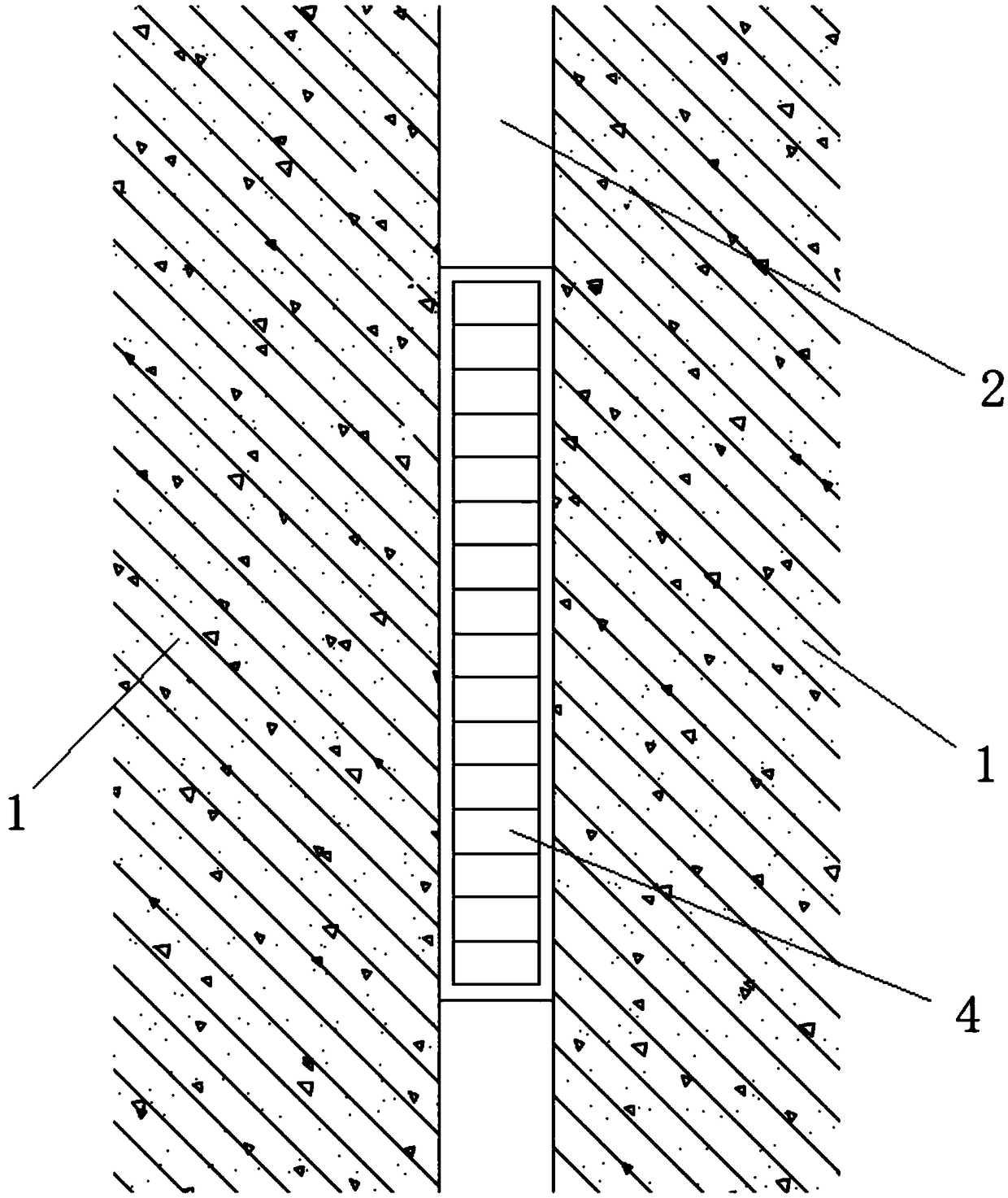

[0035] figure 1 A structural schematic view of the floor joint ventilation pipe structure provided by the embodiment of the present invention at a viewing angle; figure 2 A structural schematic view of the floor joint ventilation pipe structure provided by the embodiment of the present invention at a viewing angle; image 3 It is a structural schematic view of the joint ventilation pipe structure of the floor slab provided by the embodiment of the present invention at a viewing angle. see Figure 1-3 As shown, this embodiment provides a floor joint ventilation pipe structure, the floor joint ventilation pipe structure includes a floor, the floor is a joint floor 1, and a joint is formed between the joint floor 1, the said The lower part of the splicing seam is provided with a cover plate 2, and the cover plate 2 and the splicing seam form a ventilation groove 3;

[0036] Vents 4 are arranged on the cover plate 2 .

[0037] In this embodiment, the floor slab generally refe...

Embodiment 2

[0043] This embodiment provides a floor joint ventilation pipe structure. The floor joint ventilation pipe structure has an overall structure similar to that of Embodiment 1. The difference is that this embodiment provides a specific structure of the floor joint ventilation pipe structure.

[0044] see Figure 1-3 As shown, the floor joint ventilation pipe structure of this embodiment includes a floor, the floor is a joint floor 1, a joint is formed between the adjacent joint floors 1, and the lower part of the joint is provided with a cover plate 2 , the cover plate 2 and the seam form a ventilation groove 3;

[0045] Vents 4 are arranged on the cover plate 2 .

[0046] The spliced floor slabs described in this embodiment are SP hollow prestressed slabs. The SP hollow prestressed slabs have environmental protection, energy saving, sound insulation, shock resistance, flame retardancy, good ductility of SP slabs, large deflection before failure, and high slab safety. advant...

Embodiment 3

[0054] This embodiment provides a ventilation structure, which includes the floor joint ventilation pipe structure described in Embodiment 1 or Embodiment 2.

[0055] see Figure 1-3 As shown, the floor joint ventilation pipe structure of the ventilation structure in this embodiment includes a floor, the floor is a joint floor 1, a joint is formed between the adjacent joint floor 1, and the lower part of the joint is provided with a cover plate 2, the cover plate and the seam form a ventilation groove 3;

[0056] Ventilation openings 4 are arranged on the cover plate.

[0057] The spliced floor slabs described in this embodiment are SP hollow prestressed slabs. The SP hollow prestressed slabs have environmental protection, energy saving, sound insulation, shock resistance, flame retardancy, good ductility of SP slabs, large deflection before failure, and high slab safety. advantage.

[0058] Optionally, in this embodiment, the cover plate 2 is in close contact with the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com