Display panel and manufacturing method thereof

A display panel and substrate technology, applied in semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of packaging layer peeling, packaging failure, poor packaging, etc., to improve cracks, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

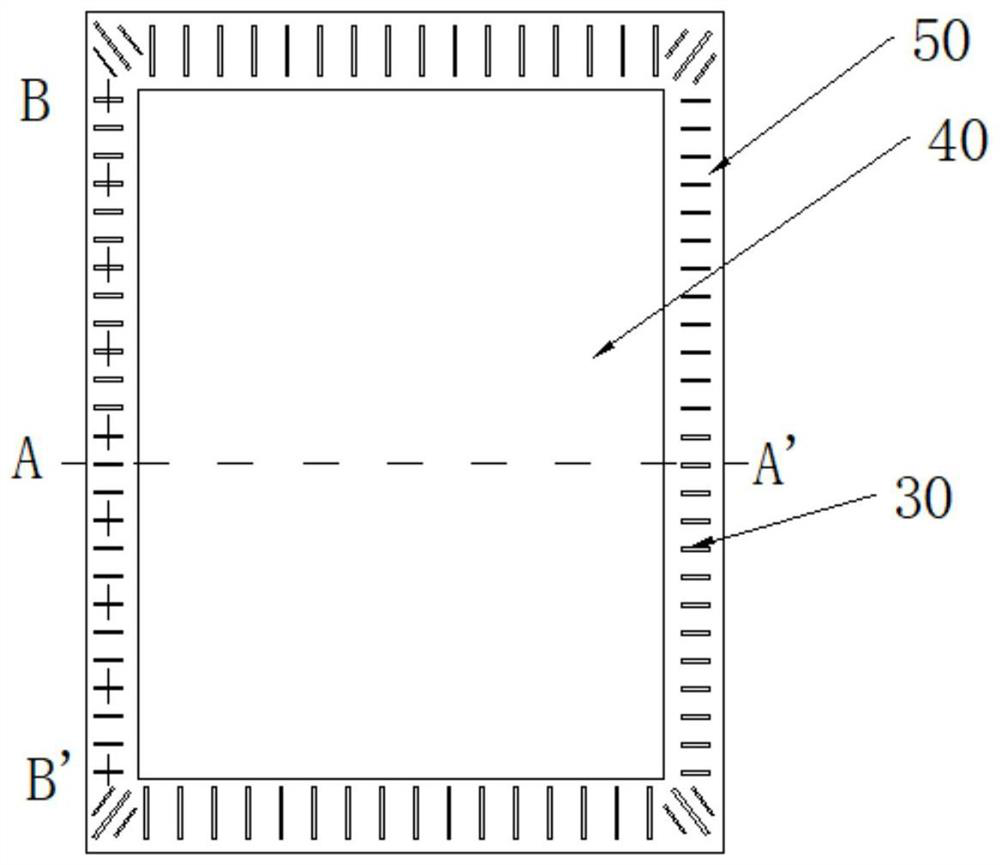

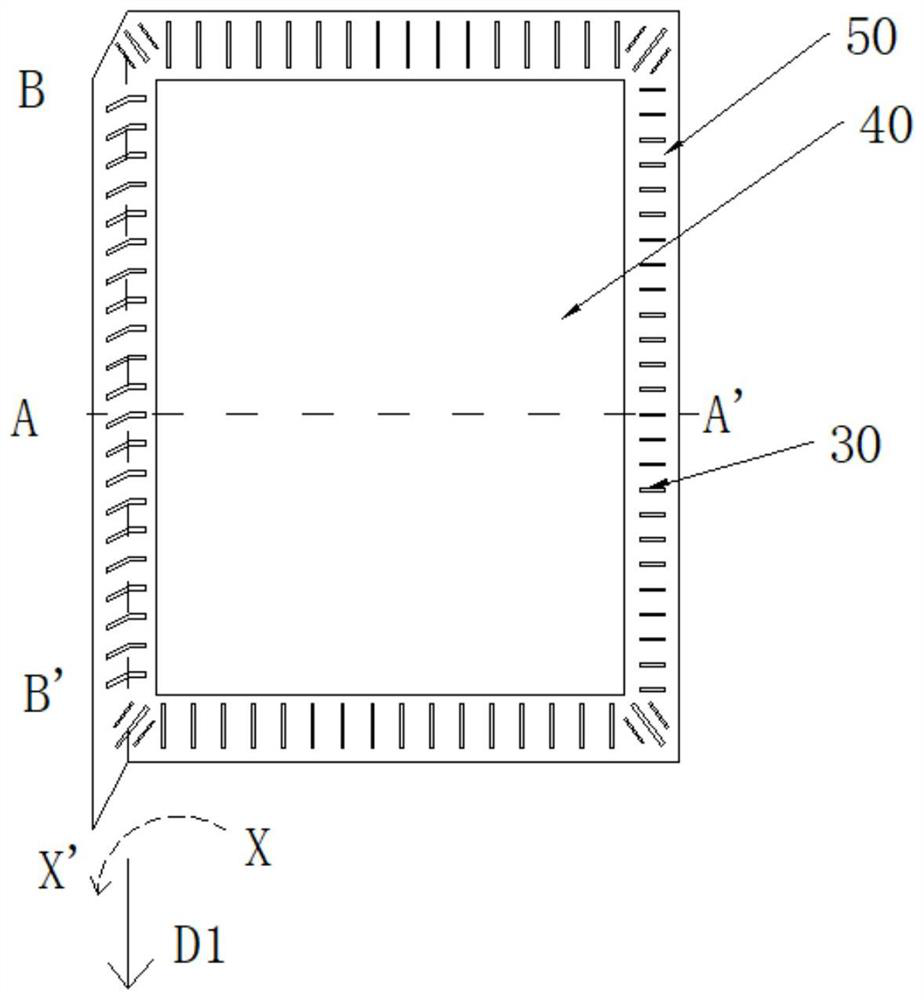

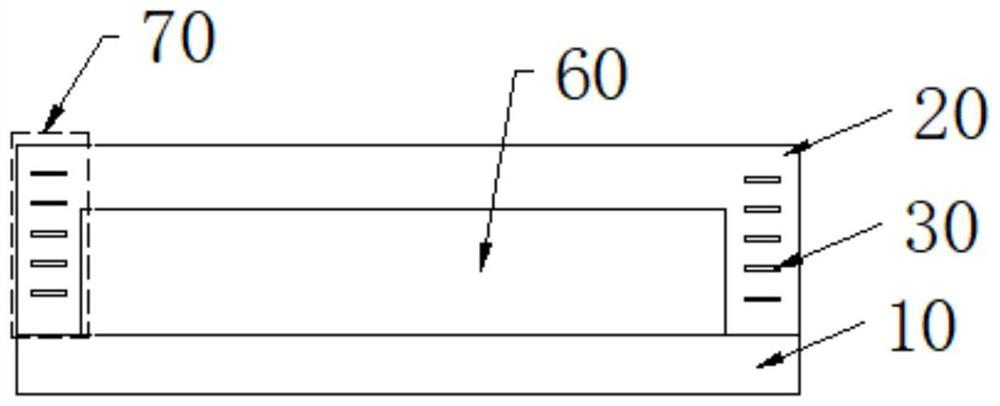

[0031] Such as figure 1 , figure 2 with image 3 As shown, a technical solution adopted in the embodiment of the present application is: a display panel includes a bending area 70, specifically, the display panel includes a flexible array substrate 10 and an encapsulation layer 20, and the encapsulation layer 20 is arranged on one side of the flexible array substrate 10 The encapsulation layer 20 in the bending area 70 is dispersed with fibrous materials 30, at least part of the extending direction of the fibrous materials 30 intersects with the first direction D1 to resist the bending stress of the bending area 70, wherein the first direction D1 is perpendicular to A plane defined by the bending direction of the bending region 70 .

[0032] The above is the core content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com