Low-density micro-expansion early-strength channeling-preventive oil well cement slurry and preparation method thereof

An oil well cement slurry and micro-expansion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of fragility, reduced compressive strength of cement stone, easy delamination, etc., and achieve good flow performance, strong Anti-channeling performance, the effect of less free water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

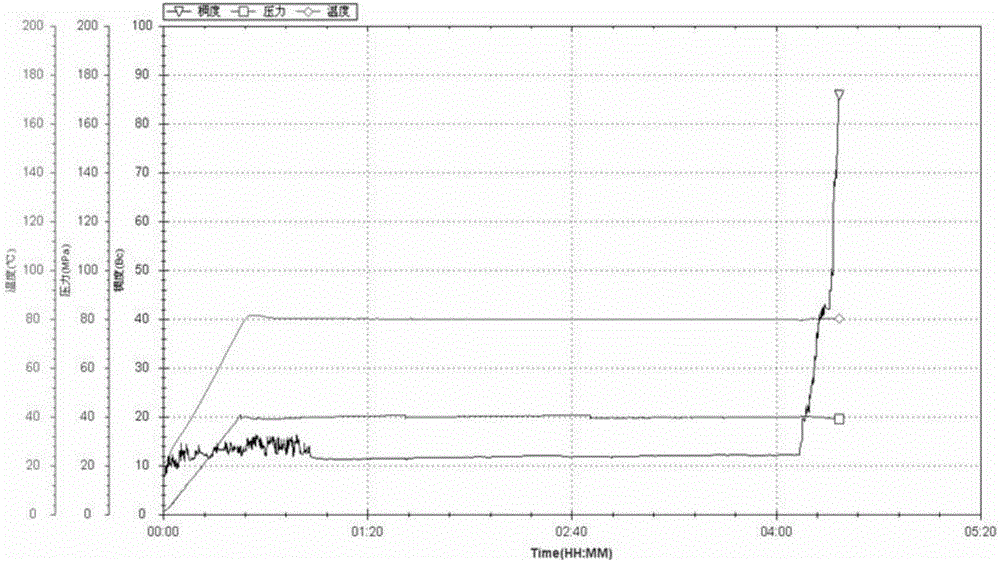

Image

Examples

Embodiment 1

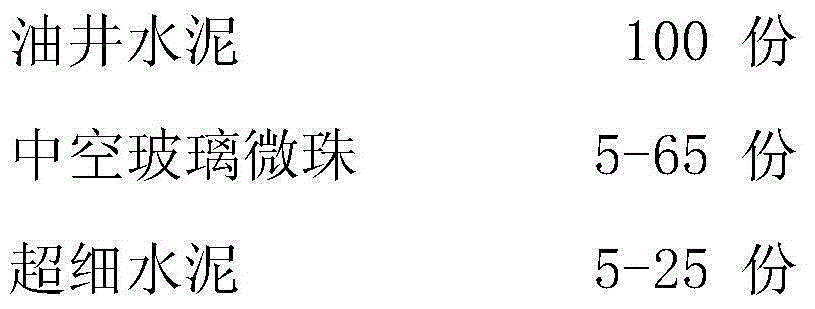

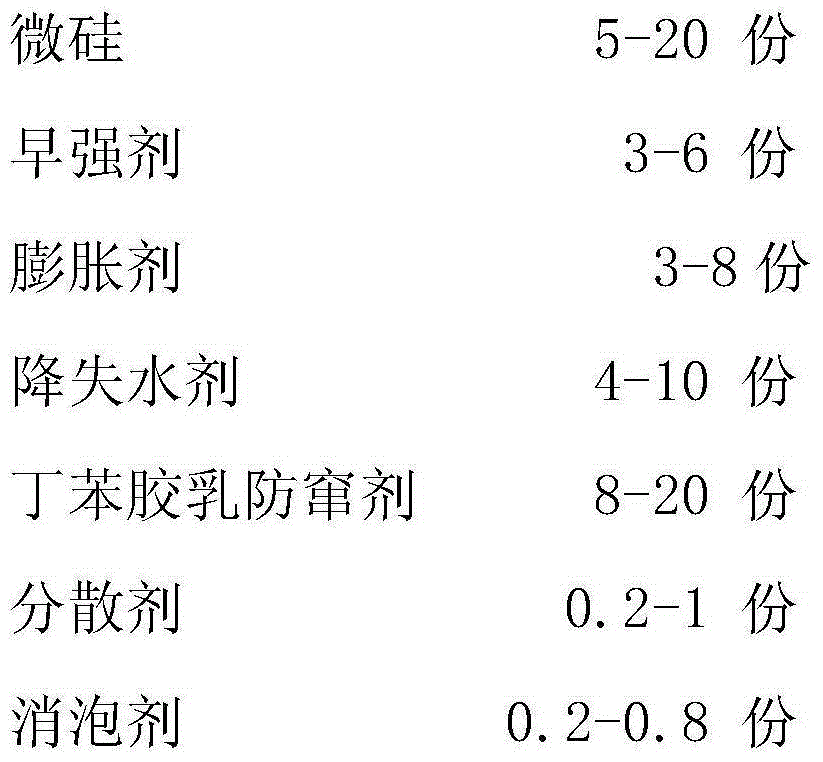

[0031] Example 1, the formula of oil well cement slurry A is: 100 parts of oil well cement, 8 parts of hollow glass beads, 5 parts of ultra-fine cement, 5 parts of microsilica, 3 parts of early strength agent, 3 parts of expansion agent, and fluid loss agent 4 parts, 8 parts of styrene butadiene latex anti-channeling agent, 0.2 part of dispersant, 0.3 part of defoamer, and 60 parts of water. The density of cement slurry is 1.55g / cm3.

Embodiment 2

[0032] In Example 2, the formula of oil well cement slurry B is: 100 parts of oil well cement, 16 parts of hollow glass beads, 10 parts of ultra-fine cement, 8 parts of microsilica, 4 parts of early strength agent, 4 parts of expansion agent, and fluid loss agent 6 parts, 10 parts of styrene butadiene latex anti-channeling agent, 0.4 parts of dispersant, 0.5 parts of defoamer, and 75 parts of water. The density of cement slurry is 1.40g / cm3.

Embodiment 3

[0033] Example 3, the formula of oil well cement slurry C is: 100 parts of oil well cement, 30 parts of hollow glass beads, 15 parts of ultra-fine cement, 9 parts of microsilica, 4 parts of early strength agent, 5 parts of expansion agent, and fluid loss agent 8 parts, 12 parts of styrene-butadiene latex anti-channeling agent, 0.5 parts of dispersant, 0.5 parts of defoaming agent, and 100 parts of water. The density of the cement slurry is 1.25g / cm3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com