Preparation method of viscosity-reducing mud-resistant polycarboxylate superplasticizer

A polycarboxylic acid and anti-mud technology, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of poor anti-mud performance of high-strength concrete, not obvious effect of reducing viscosity, and low sensitivity of dosage And other problems, to achieve good adaptability, good viscosity reduction effect, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

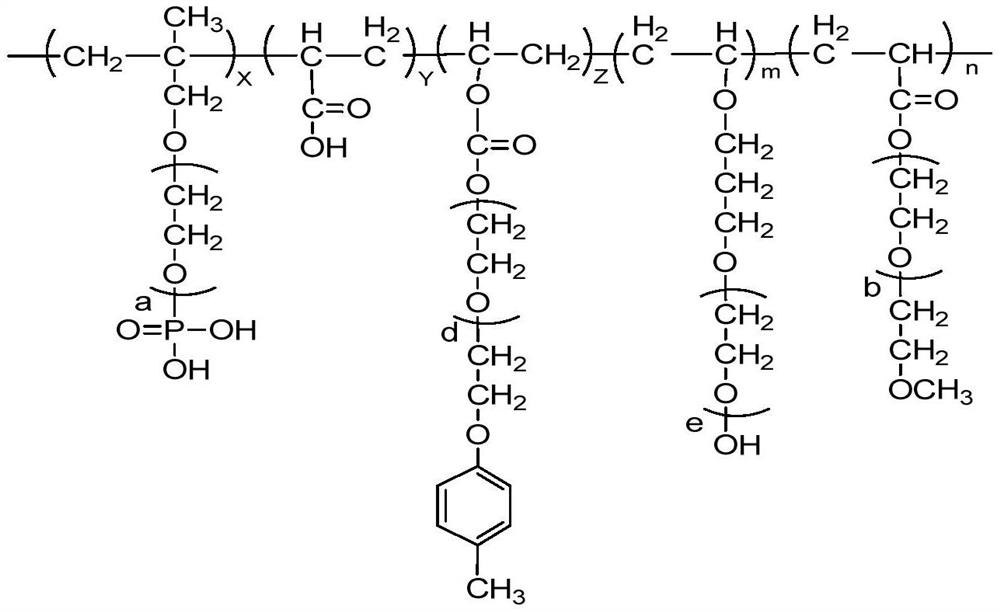

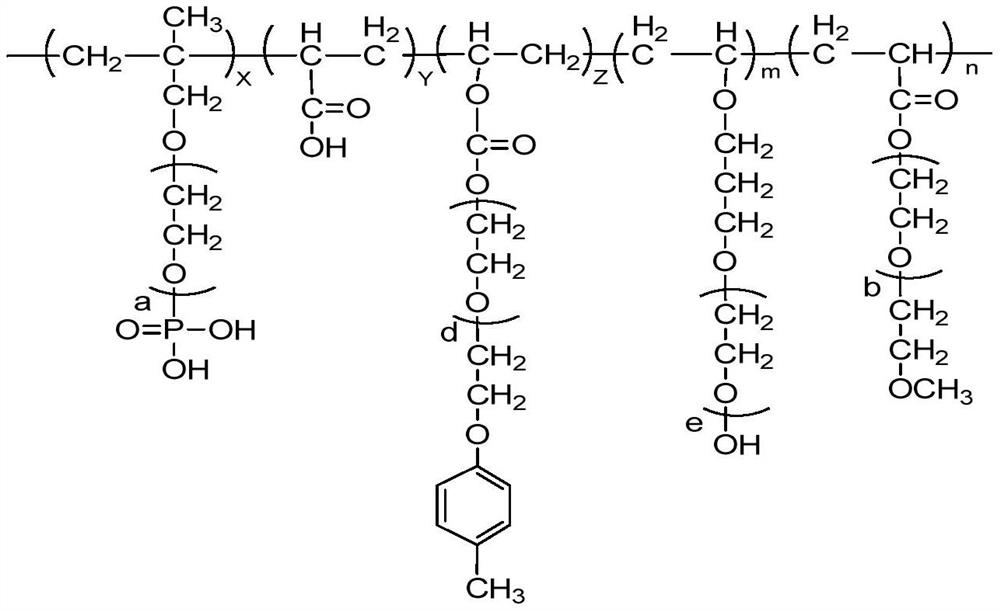

Image

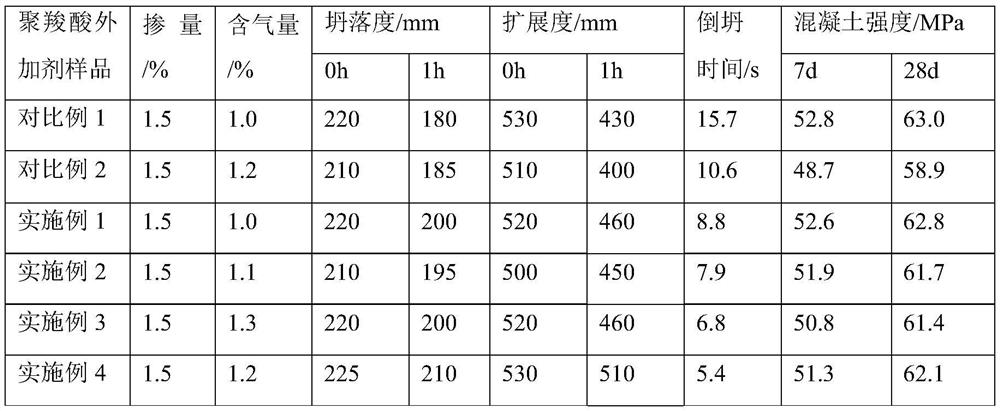

Examples

Embodiment 1

[0044] (1) Preparation of methallyl polyoxyethylene ether phosphate monomer (PP)

[0045] In parts by mass, add 100 parts of methallyl polyoxyethylene ether (HPEG, molecular weight 1200) and 10 parts of pyrophosphoric acid into a three-necked flask, pass nitrogen gas to remove water and oxygen, and react at 90°C for 10 hours. After completion, add 30 parts of deionized water to obtain methallyl polyoxyethylene ether phosphate monomer (PP).

[0046] (2) Preparation of nonylphenol polyoxyethylene ether methacrylate monomer (WP)

[0047] In parts by mass, add 100 parts of nonylphenol polyoxyethylene ether (APEO, molecular weight 600), 20 parts of methacrylic acid, 0.5-5.0 parts of p-toluenesulfonic acid and 0.3-3.0 parts of hydroquinone into the reaction flask , feed nitrogen to remove water and oxygen, heat to 110°C, react at this temperature for 5h, after the reaction, add 30 parts of deionized water to obtain nonylphenol polyoxyethylene ether methacrylate monomer (WP).

[00...

Embodiment 2

[0053] Functionalized monomer methallyl polyoxyethylene ether phosphate monomer (PP), nonylphenol polyoxyethylene ether methacrylate monomer (WP) and polyethylene glycol monomethyl ether methacrylate ( MP) is prepared respectively with embodiment 1 (1), (2) and (3).

[0054] (4) Preparation of viscosity-reducing and anti-mud type polycarboxylate superplasticizer

[0055] In parts by mass, 80 parts of methallyl polyoxyethylene ether phosphate monomer (PP), 40 parts of nonylphenol polyoxyethylene ether methacrylate monomer (WP), 40 parts of polyethylene glycol Monomethyl ether methacrylate (MP), 5 parts of acrylic acid and 100 parts of water were mixed and stirred to dissolve, and 4.0 parts of hydrogen peroxide was added, and the reaction was carried out at 25°C. Add dropwise the first mixed solution obtained by mixing 30 parts of acrylic acid and 50 parts of deionized water, and complete the dropwise addition within 2.5 hours; The second mixed solution obtained was added drop...

Embodiment 3

[0057] Functionalized monomer methallyl polyoxyethylene ether phosphate monomer (PP), nonylphenol polyoxyethylene ether methacrylate monomer (WP) and polyethylene glycol monomethyl ether methacrylate ( MP) is prepared respectively with embodiment 1 (1), (2) and (3).

[0058] (4) Preparation of viscosity-reducing and anti-mud type polycarboxylate superplasticizer

[0059] In parts by mass, 80 parts of methallyl polyoxyethylene ether phosphate monomer (PP), 60 parts of nonylphenol polyoxyethylene ether methacrylate monomer (WP), 60 parts of polyethylene glycol Monomethyl ether methacrylate (MP), 10 parts of acrylic acid and 100 parts of water were mixed and stirred to dissolve, and 5.0 parts of hydrogen peroxide was added, and the reaction was carried out at 25°C. Add dropwise the first mixed solution obtained by mixing 30 parts of acrylic acid and 50 parts of deionized water, and complete the dropwise addition within 2.5 hours; The second mixed solution obtained was added dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com