Preparation method of anti-freezing organic-hydrogel with reversible adhesion and self-healing properties

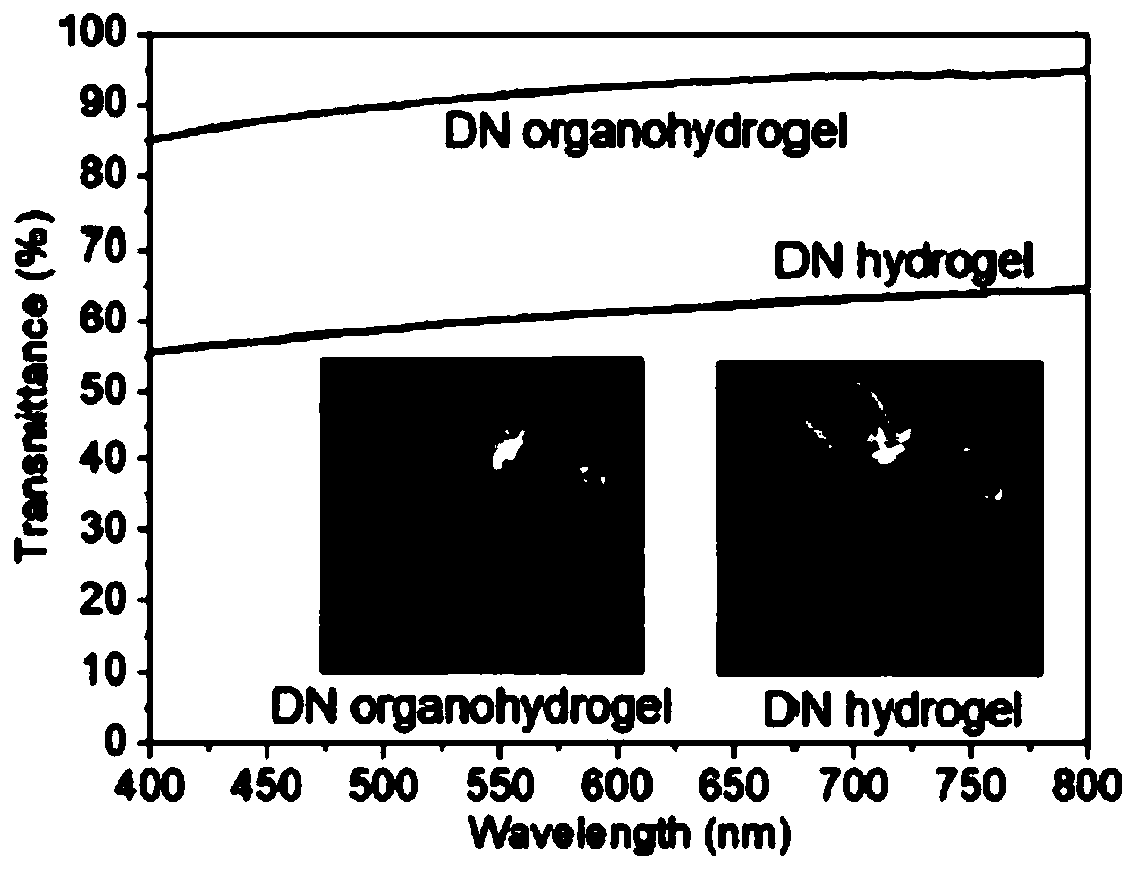

A hydrogel and organic technology, which is applied in the field of antifreeze organic-hydrogel preparation, can solve the problems of long-term use of unfavorable gel materials, decreased transparency of gel materials, and decreased adhesion of hydrogels. The effect of large-scale industrial production, stable production performance and recovery of adhesion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

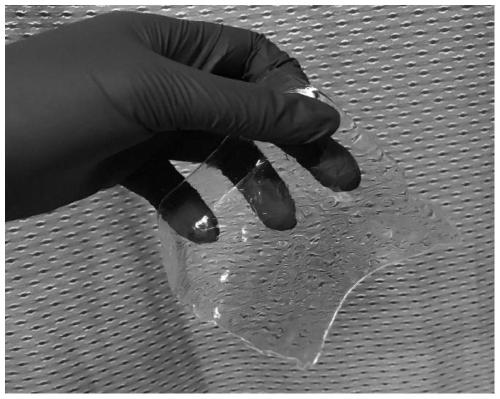

[0042] A method for preparing an organic / hydrogel with intrinsic reversible adhesion, ultra-long stretchability, transparency and conductivity, comprising the steps of:

[0043] Step 1) Preparation of polyvinyl alcohol (PVA) aqueous solution: Weigh 11.1g of PVA in a round bottom flask, add 100g of deionized water, seal and swell for 24h, then install a condensation device, heat and stir at 90°C for 2h to dissolve PVA, and obtain the concentration 10wt% PVA solution;

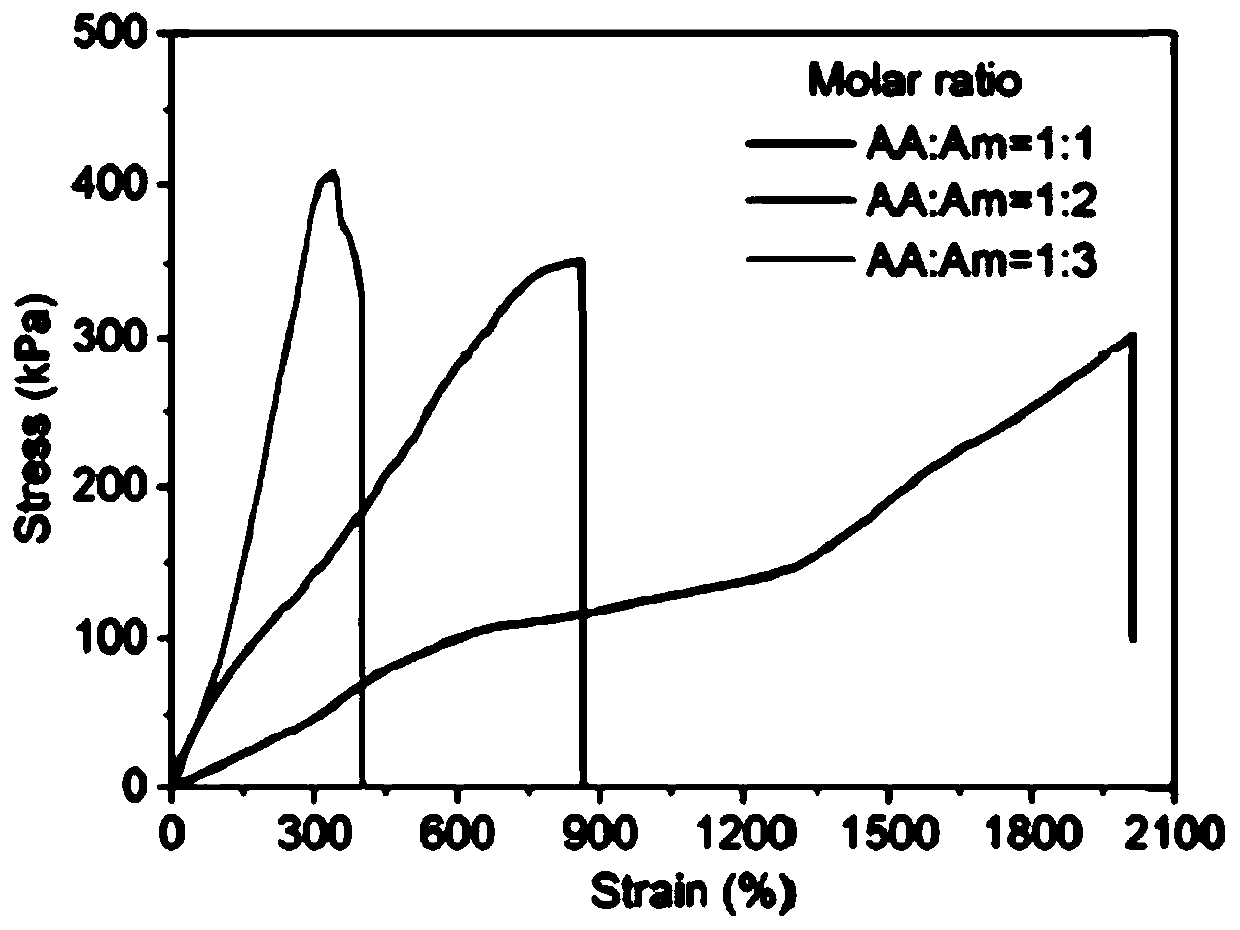

[0044] Step 2) preparation of PVA / monomer pregel solution: in the round bottom flask, adding 6mL concentration successively is the PVA aqueous solution of 10wt%, and 0.2mL concentration is the H of 10wt%. 2 SO 4 , 3.15g AA, 9mL glycerin, 2.82g Am, 0.6015g KCl, 0.05g α-ketoglutaric acid, 1mL concentration is 5wt% glutaraldehyde aqueous solution;

[0045] Step 3) UV light gelation of the pre-gel solution: add the uniformly mixed PVA / monomer pre-gel solution into the mold (tetrafluoroethylene plate, glass plate an...

Embodiment 2

[0047] A method for preparing an organic / hydrogel with intrinsic reversible adhesion, ultra-long stretchability, transparency and conductivity, comprising the steps of:

[0048] Step 1) Preparation of polyvinyl alcohol (PVA) aqueous solution: Weigh a certain amount of 5.3g of PVA in a round bottom flask, add 100g of deionized water, seal and swell for 24h, then install a condensation device, heat and stir at 90°C for 2h to dissolve the PVA, Obtaining concentration is the PVA solution of 5wt%;

[0049] Step 2) preparation of PVA / monomer pregel solution: in the round bottom flask, adding 6mL concentration successively is the PVA aqueous solution of 5wt%, and 0.2mL concentration is the H of 10wt%. 2 SO 4, 3.16g AA, 9mL glycerin, 2.82g Am, 0.6015g KCl, 0.05g α-ketoglutaric acid, 1mL concentration is 5wt% glutaraldehyde aqueous solution;

[0050] Step 3) UV light gelation of the pre-gel solution: add the uniformly mixed PVA / monomer pre-gel solution into the mold (tetrafluoroethyl...

Embodiment 3

[0055] A method for preparing an organic / hydrogel with intrinsic reversible adhesion, ultra-long stretchability, transparency and conductivity, comprising the steps of:

[0056] Step 1) Preparation of polyvinyl alcohol (PVA) aqueous solution: Weigh 11.1g of PVA in a round bottom flask, add 100g of deionized water, seal and swell for 24h, then install a condensation device, heat and stir at 90°C for 2h to dissolve PVA, and obtain the concentration 10wt% PVA solution;

[0057] Step 2) preparation of PVA / monomer pregel solution: in the round bottom flask, adding 6mL concentration successively is the PVA aqueous solution of 10wt%, and 0.2mL concentration is the H of 10wt%. 2 SO 4 , 3.15g AA, 9mL glycerin, 5.64g Am, 0.6015g KCl, 0.05g α-ketoglutaric acid, 1mL concentration is 5wt% glutaraldehyde aqueous solution;

[0058] Step 3) UV light gelation of the pre-gel solution: add the uniformly mixed PVA / monomer pre-gel solution into the mold (tetrafluoroethylene plate, glass plate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com