Groove type turning machine for sludge

A technology of turning and polishing machine and sludge, which is applied in the fields of organic fertilizer, organic fertilizer preparation, chemical industry, etc., can solve the problems of insufficiently uniform turning and insufficient transmission efficiency, and achieve the improvement of transmission efficiency, energy saving and uniform fermentation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

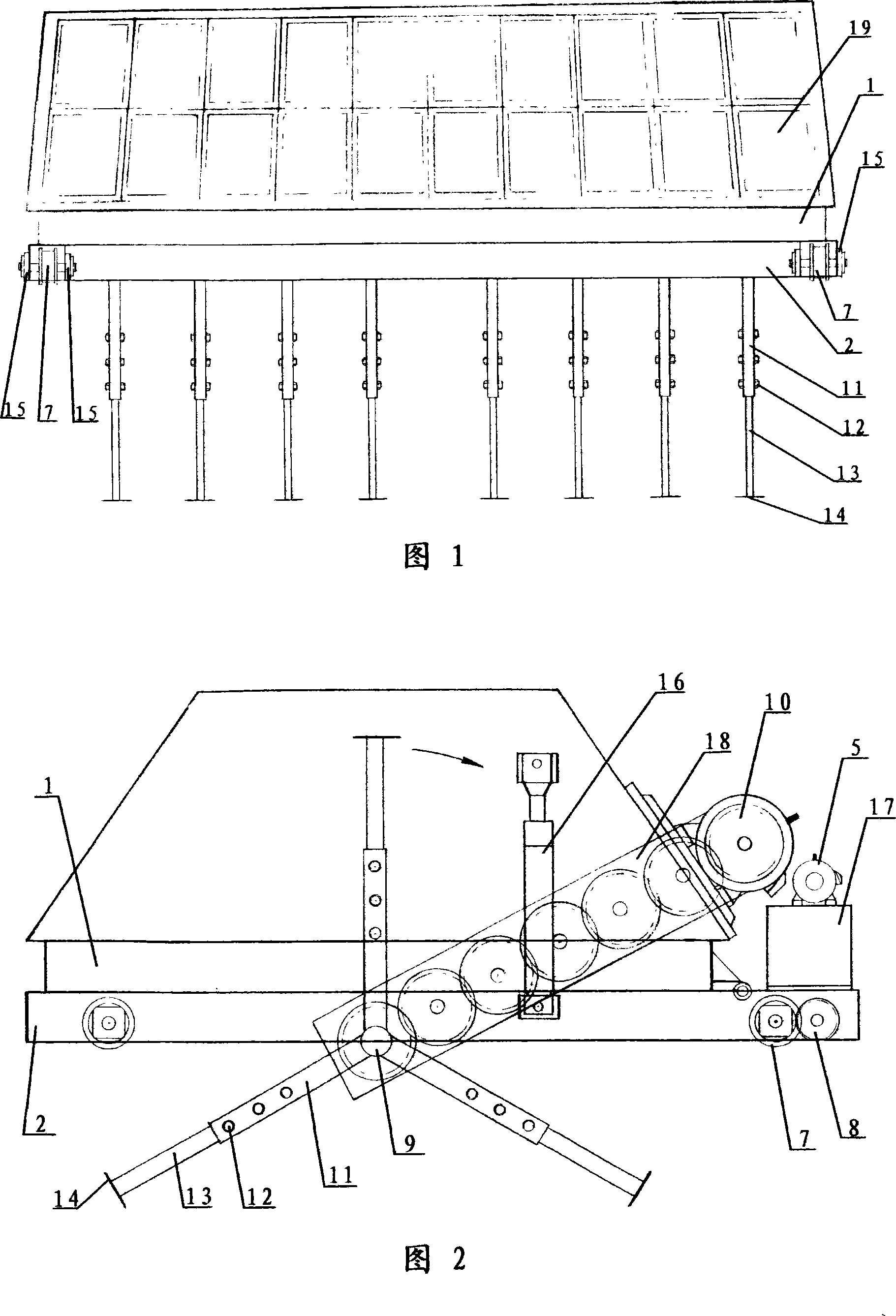

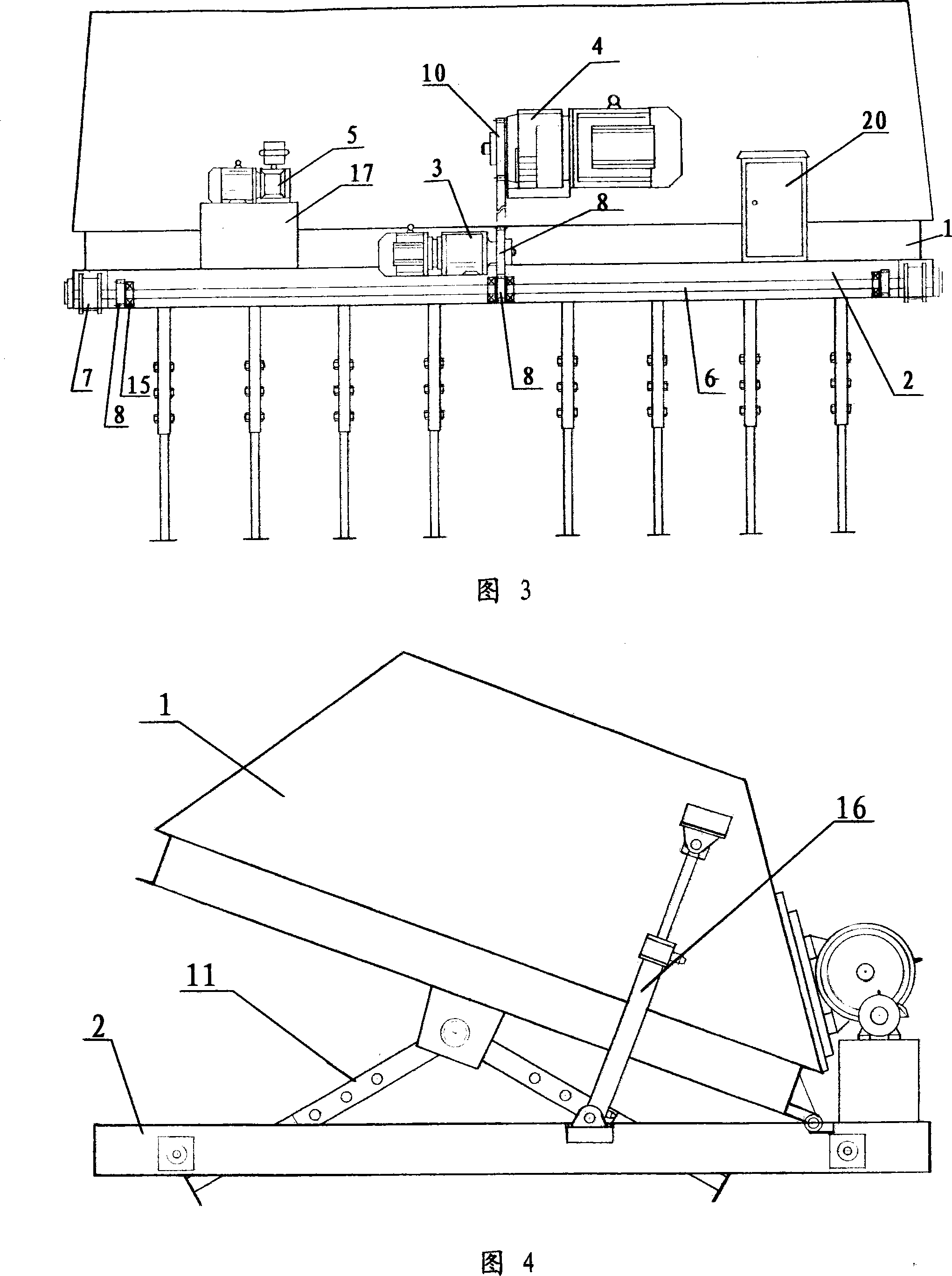

[0017] As shown in Figures 1 to 3, the trough sludge turning and throwing machine of the present invention includes an upper machine base 1 and a lower machine base 2, and a hydraulic lifting device is arranged between the upper machine base 1 and the lower machine base 2. Lifting device comprises hydraulic pump station 5, hydraulic oil tank 17 and the hydraulic cylinder that is arranged on the upper machine base 1, the hydraulic cylinder 16 that is arranged on the lower machine base 2, in upper machine base 1, horizontally arranges turning and throwing assembly, turning and throwing assembly and The speed-regulating motor 4 is connected, and the front and rear sides of the lower base 2 are provided with a traveling mechanism, and the traveling mechanism is connected with the speed-regulating deceleration motor 3.

[0018] The turning and throwing assembly includes a rake tooth main shaft 9 horizontally mounted in the upper machine base 1, and several rake bar assemblies are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com