Method for preparing organic fertilizer by utilizing kitchen garbage

A technology for kitchen waste and organic fertilizer, which is applied in the field of preparing organic fertilizer by using kitchen waste, can solve problems such as environmental pollution, and achieve the effects of promoting plant growth, solving environmental pollution and realizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

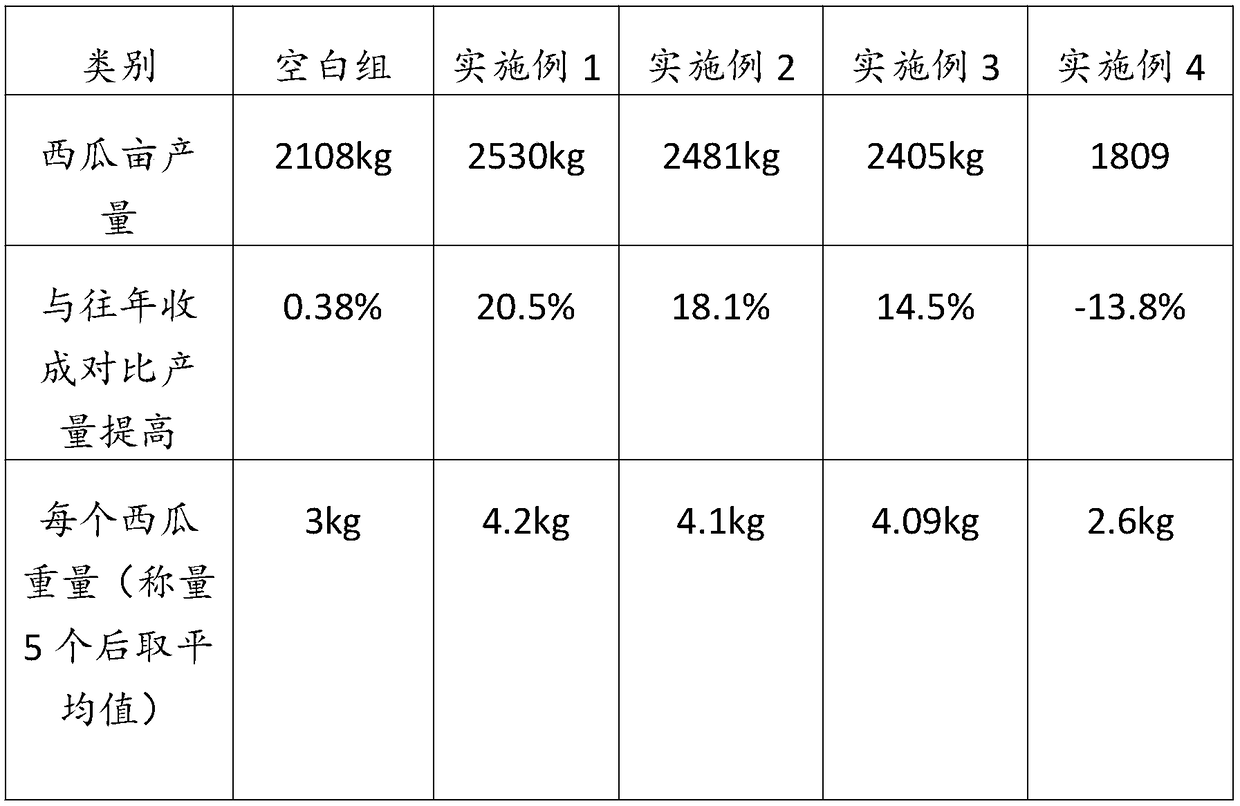

Examples

Embodiment 1

[0030] A method for preparing organic fertilizer from kitchen waste, characterized in that it comprises the following steps:

[0031] (1) Sorting and crushing: Sorting the kitchen waste, sorting out the organic matter and removing the sundries in the kitchen waste that cannot be made into fertilizers, and then crushing the sorted organic matter to obtain organic waste particles with uniform particle size The mixture, at this time, the oil content measured by the instrument is 350mg / L; wherein, the sundries that cannot be made into fertilizers include metal sundries, glass sundries, plastic sundries, wooden sundries, dust and stone sundries;

[0032] (2) Filtration to remove oil slicks: After the mixture of organic waste particles was allowed to stand for 3 hours, filter to remove the upper layer of oil slicks to obtain organic waste particles;

[0033] (3) Enzymolysis treatment: add compound enzyme to the organic waste particles in step (2), and carry out enzymolysis treatment...

Embodiment 2

[0040] A method for preparing organic fertilizer from kitchen waste, characterized in that it comprises the following steps:

[0041] (1) Sorting and crushing: Sorting the kitchen waste, sorting out the organic matter and removing the sundries in the kitchen waste that cannot be made into fertilizers, and then crushing the sorted organic matter to obtain organic waste particles with uniform particle size The mixture, at this time, the oil content measured by the instrument is 410mg / L; wherein, the sundries that cannot be made into fertilizers include metal sundries, glass sundries, plastic sundries, wooden sundries, dust and stone sundries;

[0042] (2) Filtration to remove oil slicks: After the mixture of organic waste particles was allowed to stand for 2 hours, filter to remove the upper layer of oil slicks to obtain organic waste particles;

[0043] (3) Enzymolysis treatment: add compound enzyme to the organic waste particles in step (2), and carry out enzymolysis treatment...

Embodiment 3

[0050] A method for preparing organic fertilizer from kitchen waste, characterized in that it comprises the following steps:

[0051] (1) Sorting and crushing: Sorting the kitchen waste, sorting out the organic matter and removing the sundries in the kitchen waste that cannot be made into fertilizers, and then crushing the sorted organic matter to obtain organic waste particles with uniform particle size The mixture, at this time, the oil content measured by the instrument is 386mg / L; wherein, the sundries that cannot be made into fertilizers include metal sundries, glass sundries, plastic sundries, wooden sundries, dust and stone sundries;

[0052] (2) Filtration to remove oil slicks: After the mixture of organic waste particles was allowed to stand for 4 hours, filter to remove the upper layer of oil slicks to obtain organic waste particles;

[0053] (3) Enzymolysis treatment: add compound enzyme to the organic waste particles in step (2), and carry out enzymolysis treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com