Flat black tea (Black Jinkui) and making process thereof

A flat-shaped black tea and production process technology, applied in the direction of tea treatment before extraction, etc., to achieve the effect of great popularization and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

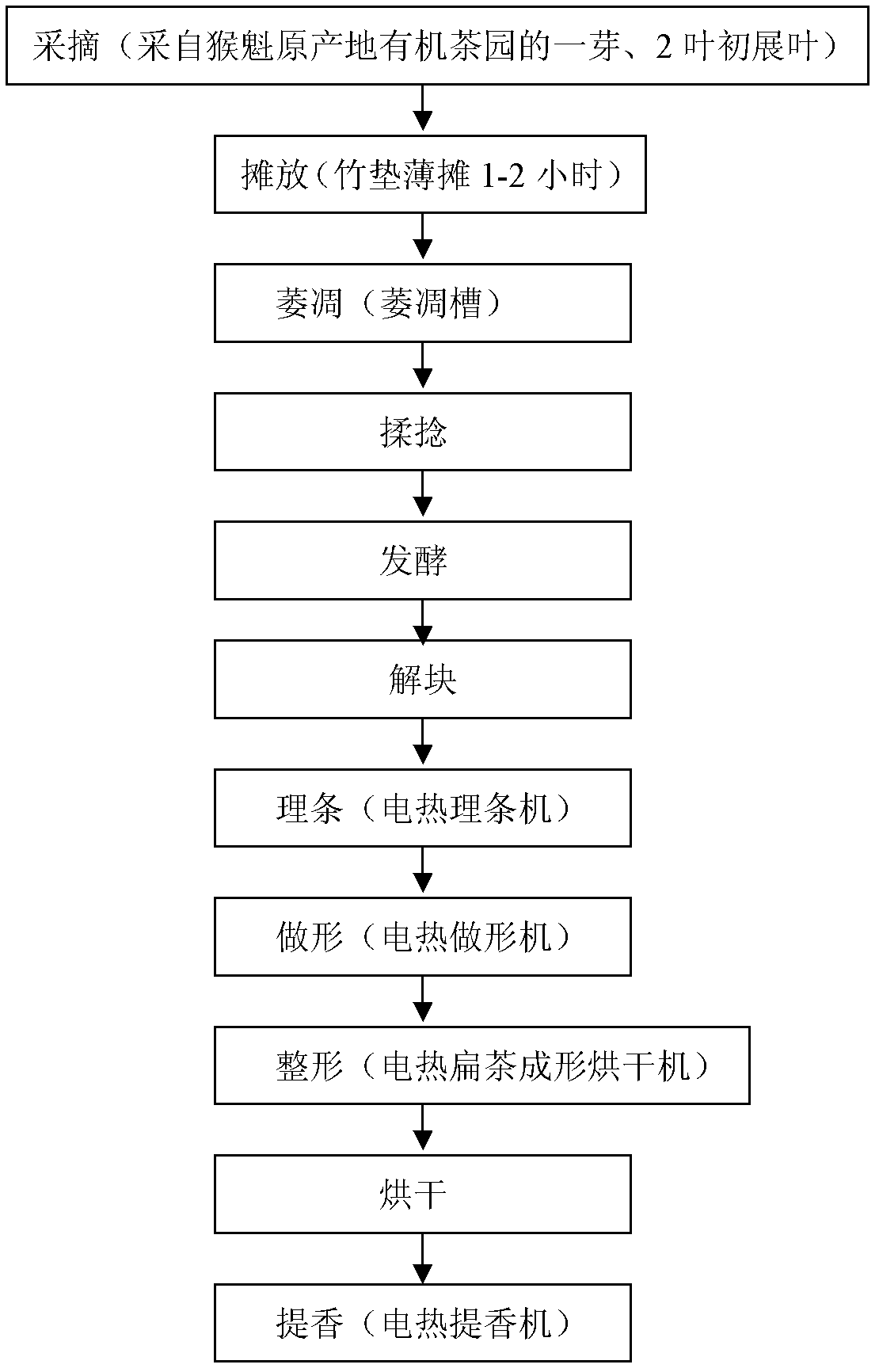

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Production process of Hongjinkui in spring

[0061] The spring buds and leaves collected from the organic tea base are first placed on a bamboo mat and spread for about 1-2 hours. Due to the large amount of rain and humidity in spring, the spreading time is slightly longer, which is conducive to the distribution of water and green grass on the surface of the buds and leaves. When withering, due to the low temperature and high humidity in spring, the withering temperature in the withering tank should be increased to 39-40°C, and then lowered to 37-38°C in the later period, and the time is usually controlled at 5-6 hours. When kneading, because the buds and leaves are tender in spring, the kneading time should be controlled within 4-5 minutes, and knead quickly and lightly. Fermentation is an important process for the formation of the color, aroma and taste of Hongjinkui brown. Usually, the fermentation temperature is around 45°C and the time is about 5 hours. ...

Embodiment 2

[0062] Example 2: Production process of summer red gold Kui mechanism

[0063] Due to the high temperature and dryness in summer, there is a certain difference in the production process compared with spring tea. When the buds and leaves are harvested, immediately put them on a bamboo mat to cool down, with a thickness of about 1 cm, and blow cold wind to cool down to avoid browning. In the withering process, the withering temperature can be appropriately lowered to keep it at about 38°C, so as to avoid drying and browning due to excessive temperature. When kneading, because the buds and leaves are relatively thick in summer, the kneading time should be extended, which can be controlled at about 5-6 minutes, and "heavy pressure" should be used for 2 minutes to make the cell crushing rate reach about 60%. Deblocking can be applied to mechanical deblocking, which has the advantages of fast speed and high deblocking rate. Summer tea fermentation should adopt "three reduction" me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com