Process for processing black tea of golden camellia

A processing method and technology for camellia tea, applied in the processing field of golden camellia black tea, can solve the problems of inconspicuous aroma of golden camellia products, not bright red color of the soup, not suitable for golden camellia black tea, etc. , the effect of floral fragrance is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

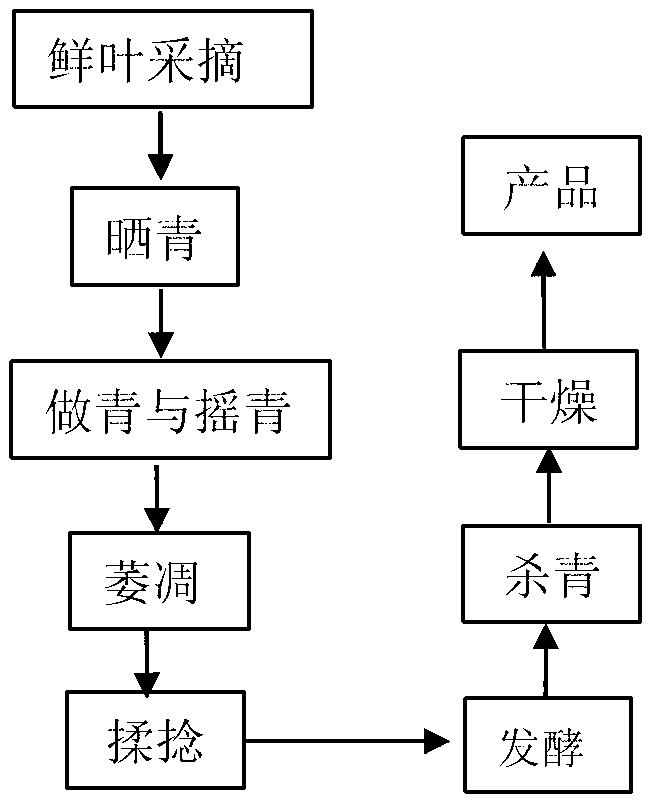

Image

Examples

Embodiment 1

[0030] Pick 30kg of fresh leaves of Camellia japonica that have just changed from purple to green, and dry them for 30 minutes to make the fresh leaves lose 5% of their water, and then spread them to cool and move them to an air-conditioned room for greening. The temperature in the air-conditioned room is controlled at 20°C, and the relative humidity in the air-conditioned room is 80%; the green is shaken three times at a speed of 10r / min, and the interval between each shaking is 2.0h. After the greening is completed, the tea leaves can be cut into sections after revealing the fragrance of flowers, and each section has a length of 2 to 3 cm. The cut tea leaves can be withered, and the water content of the tea leaves after withering is 65% for rolling. Kneading method: empty kneading for 15 minutes, followed by light pressure for 8 minutes, further pressure for 10 minutes, and finally loose pressure for 8 minutes, deblocking to obtain coarse tea leaves. The crude tea leaves we...

Embodiment 2

[0033] Pick 80kg of fresh leaves of Camellia japonica that have just changed from purple to green, and dry them for 30 minutes to make the fresh leaves lose 4% of their water, and then spread them to cool and move them to an air-conditioned room for greening. The temperature in the air-conditioned room is controlled at 24°C, and the relative humidity in the air-conditioned room is 85%; the green is shaken 4 times at a speed of 6r / min, and the interval between each shaking is 0.5h. After the greening is completed, the tea leaves can be cut into sections after revealing the fragrance of flowers, and each section has a length of 2 to 3 cm. The cut tea leaves can be withered, and the water content of the tea leaves after withering is 55% for rolling. Kneading method: empty kneading for 20 minutes, followed by light pressure for 6 minutes, further pressure for 9 minutes, and finally loose pressure for 4 minutes, and deblocking to obtain coarse tea leaves. The crude tea leaves were...

Embodiment 3

[0036]Pick 60kg of fresh leaves of Camellia japonica that have just changed from purple to green, and dry them for 30 minutes to make the fresh leaves lose 3% of their water, and then spread them to cool and move them to an air-conditioned room for greening. The temperature in the air-conditioned room is controlled at 25°C, and the relative humidity in the air-conditioned room is 83%; the green is shaken three times at a speed of 7r / min, and the interval between each shaking is 1.5h. After the greening is completed, the tea leaves can be cut into sections after revealing the fragrance of flowers, and each section has a length of 2 to 3 cm. The tea leaves that have been cut into sections can be withered, and the water content of the tea leaves after withering is 50% for rolling. Kneading method: empty kneading for 10 minutes, followed by light pressure for 3 minutes, further pressure for 8 minutes, and finally loose pressure for 5 minutes, deblocking to obtain coarse tea leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com