Patents

Literature

46results about How to "Floral fragrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for processing black tea of golden camellia

InactiveCN102987034ASignificant comprehensive benefitsFully fermentedTea substituesMicrowaveBlack tea

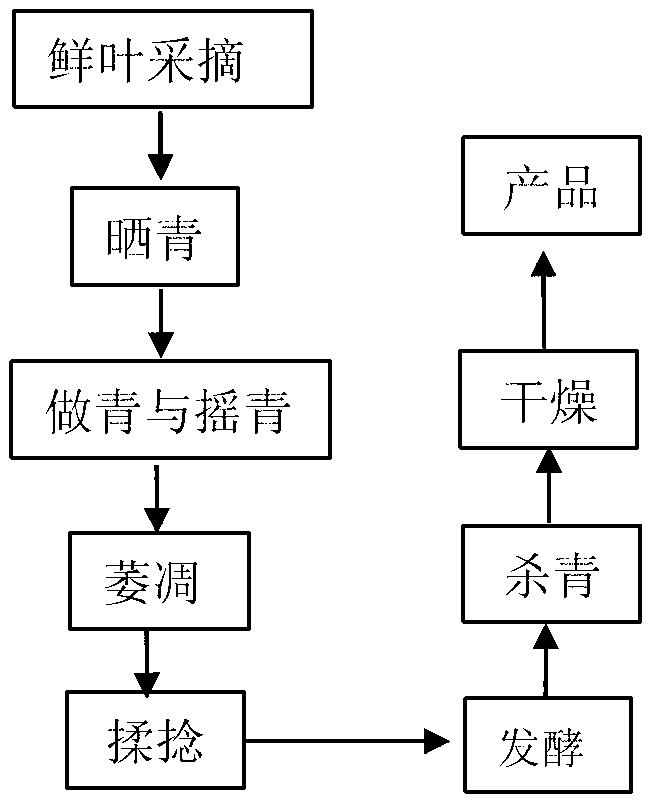

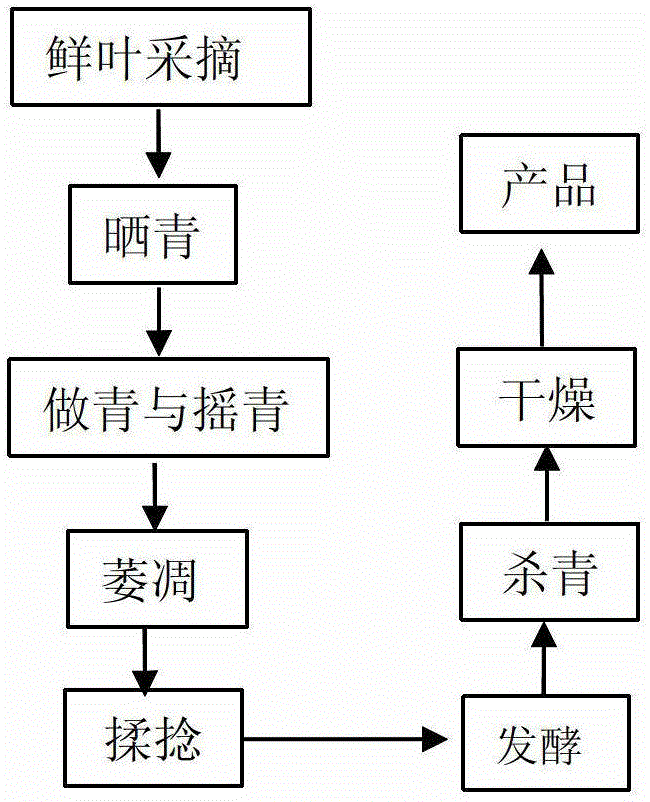

The invention relates to a process for processing black tea of golden camellia. The processing process comprises the steps of (1) picking, wherein fresh leaves of the golden camellia, which just change from purple to green, are picked; (2) sunning, wherein the water loss of fresh leaves reach 3-8% through sunning treatment; (3) shaking and rocking, wherein leaves are subjected to shaking treatment in an air-conditioning room, and rocking is conducted twice to five times; (4) withering, wherein tea leaves are cut into sections and withered, and the water content in tea leaves after withering is within a range of 55%-65%; (5) rolling, wherein the rolling procedure comprises vacuum rolling, slight pressing, compressing, loosening and deblocking; (6) fermenting, wherein fermentation is conducted for 8-10 hours at a temperature within a range of 24-25 DEG C; (7) removing water, wherein microwave water-removing is conducted for 2-7min at a temperature within a range of 100-110 DEG C; and (8) drying, wherein drying is conducted in a perfuming machine to obtain the black tea of the golden camellia. According to the process for processing the black tea of the golden camellia, the black tea of the golden camellia has the fragrance of flowers, the fragrance is evident, the liquor color is red, the taste is mellow, fresh and sweet, and the quality is unique.

Owner:GUANGXI FUXIN SCI & TECH

Okra glutinous rice wine and preparation method thereof

InactiveCN103525660AFloral fragranceAvoid pollutionMicroorganism based processesAlcoholic beverage preparationNutritionMouthfeel

Okra glutinous rice wine is characterized by being prepared through the steps as follows: raw material selection, preparation of an okra flower extracting solution, rice soaking, glutinous rice wine preparation, okra flower extracting solution and glutinous rice compositing, sterilization and the like. The preparation method is simple in production technology and low in cost; and the okra glutinous rice wine is rich in nutriment and soft in flavor, integrates functions such as nutrition, health care, diet therapy and the like, and has a better consumption prospect.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Green tea making method

ActiveCN101961057AFloral fragranceVisibly resistant to brewingPre-extraction tea treatmentEnzymeBiology

The invention discloses a green tea making method. The method comprises the following steps of: 1) spreading, 2) shaking and throwing, 3) enzyme-removing, 4) rolling, 5) firstly carding, 6) secondly carding, 7) drying, and 8) finishing and storing. The invention has the advantages that the green tea made by using the method is obviously flowery, can endure repeated infusions, can partially eliminate some bitter thereof and can decrease the gastro-enteric stimulation on human body.

Owner:开化兰韵高山茶经营部

Maca teabag and preparation method thereof

The invention relates to a maca teabag and a preparation method thereof. The maca teabag is prepared from the raw materials of 10-15 parts of maca, 5-8 parts of raspberries, 3-6 parts of barley, 2-4 parts of osmanthus fragrans and 1-3 part(s) of Pu-Er ripe tea through the steps of raw material selecting, smashing, screening with a vibrating screen, weighting, component mixing and final subpackage. The maca teabag is reasonable in components and ratio design, and rich in nutrition, and the effects of all components are supplementary to one another; the preparation method is simple and convenient, and the cost is low; the maca teabag is prepared from natural components completely, so that original taste and flavour are kept, the tea soup of the maca teabag is brownish yellow, strong in wheat flavor and flower fragrance, and mellow in taste; the dissolution rate is high, extract is multiple, brewing resistance is achieved, maca teabag is carried and drunk conveniently by people, and a new beverage with the efficacities of tonifying kidney, building body and resisting fatigue is provided.

Owner:HANGZHOU EFUTON TEA

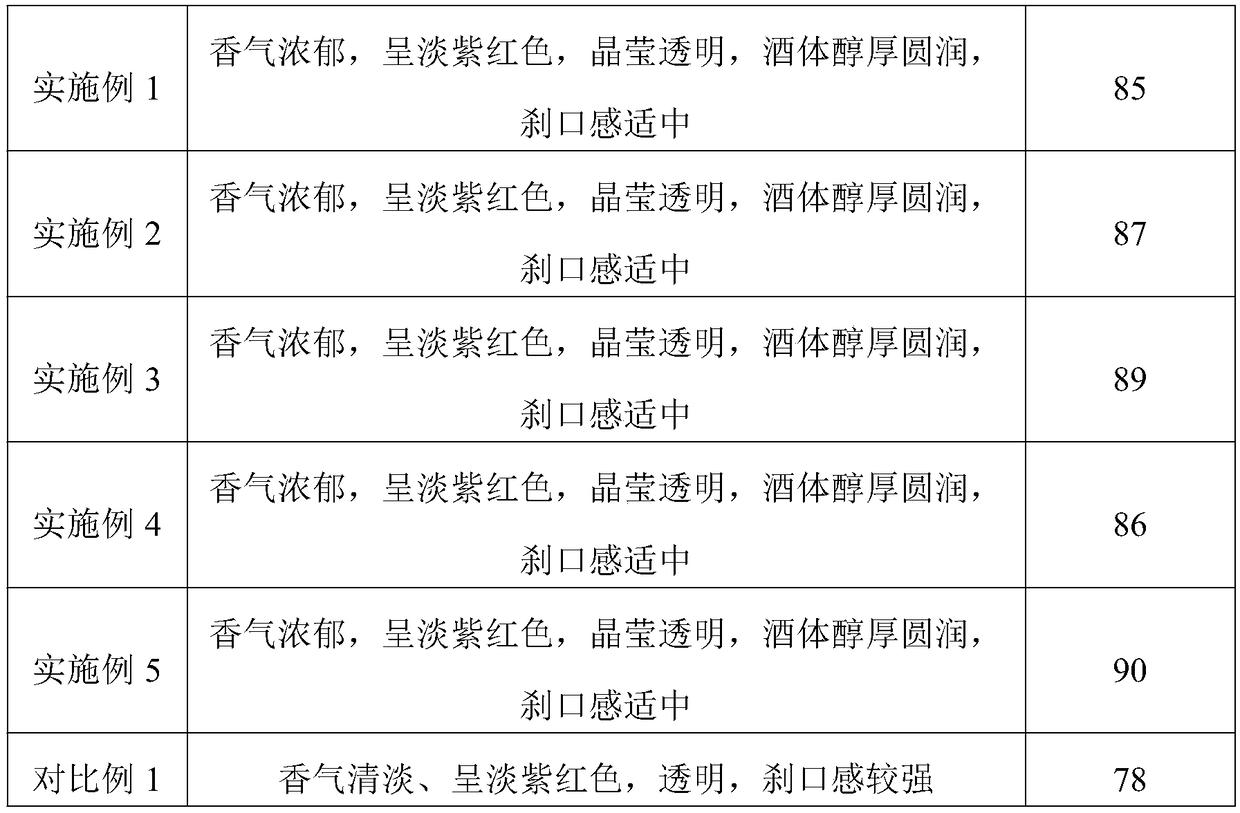

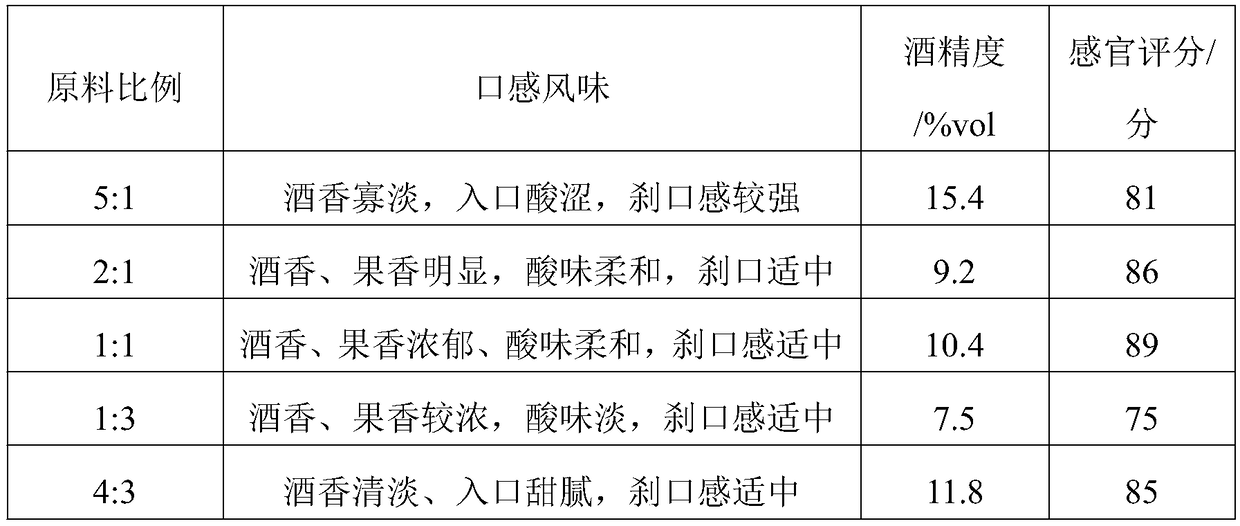

Brewing method for myrtle and Kyoho grape wine

The invention provides a brewing method for myrtle and Kyoho grape wine. The method comprises the following several steps: Step A: preparation of myrtle juice; Step B: preparation of Kyoho grape juice; Step C: preparation of fermentation broth; Step D: mixed fermentation; Step E: ageing; Step F: fining and clarifying; Step G: blending and freezing; Step H: sterilizing and filling. The brewing method disclosed by the invention has the beneficial effects that (1) the technical problems that Kyoho grapes are not suitable for brewing wine and myrtle is not suitable for brewing wine in a full-fermentation mode are solved; (2) techniques of freezing concentration, low temperature fermentation and the like are adopted, loss of nutritional ingredients is reduced, and brewed myrtle and Kyoho grape wine is obvious in flower and fruity fragrance, and exquisite and mellow in mouthfeel; (3) the product is rich in nutrition and has a good auxiliary curative effect for weakness, deficiency of blood, neurasthenia and the like after illness.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Orchid-shaped black tea making process

InactiveCN102715295ANice appearanceSoup color bright red and yellowPre-extraction tea treatmentFragrance extractionCarding

The invention relates to an orchid-shaped black tea making process, which comprises the steps of picking, spreading and airing, sunning, fixation, withering, carding, fermentation, first drying, fragrance extraction and the like. Black tea which is processed through the process is flat, straight, graceful and orchid-shaped, the appearance is attractive, the tea soup is reddish yellow and bright, the fragrance is pleasing and the internal quality of excellent.

Owner:句容市张庙茶场有限公司

Compressed tea flower and white tea cake and preparation method thereof

InactiveCN105815477AEfficient bindingGreat tastePre-extraction tea treatmentAdditive ingredientPolyphenol

The invention relates to the technical field of white tea cake preparation, in particular to a compressed tea flower and white tea cake and a preparation method thereof .The preparation method includes the steps of tea flower preparation, white tea preparation and mixing forming .After tea flowers and white tea are mixed at the mass ratio of 0.7:1.3, stream-pressure softening treatment is carried out with a steam machine, and roasting treatment is carried out multiple times, so that nutritional ingredients in tea flowers and nutritional ingredients in white tea are effectively combined, it is ensured that tea cake leaves are oily, and inlaid with golden yellow tea flowers, the tea cake is strong and refreshing in aroma, obvious in flowery fragrance, sweet and tasty .Loss of the aroma, the beneficial substance tea polyphenol and the like in the processing process is reduced, and dehydration is uniform; the taste of the tea cake is improved.

Owner:贵州湄潭兰馨茶业有限公司

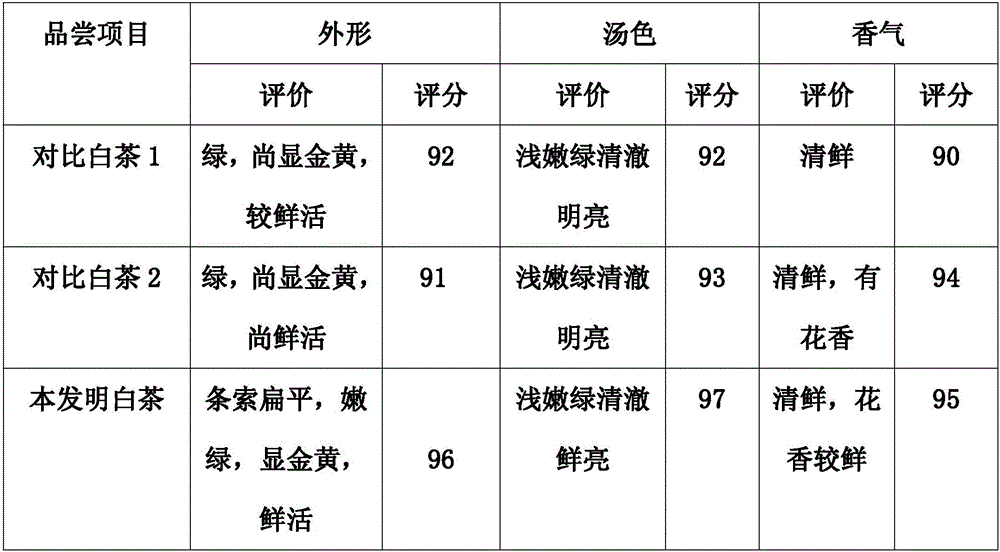

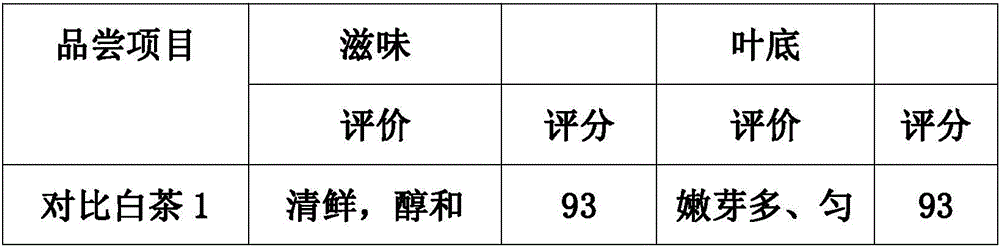

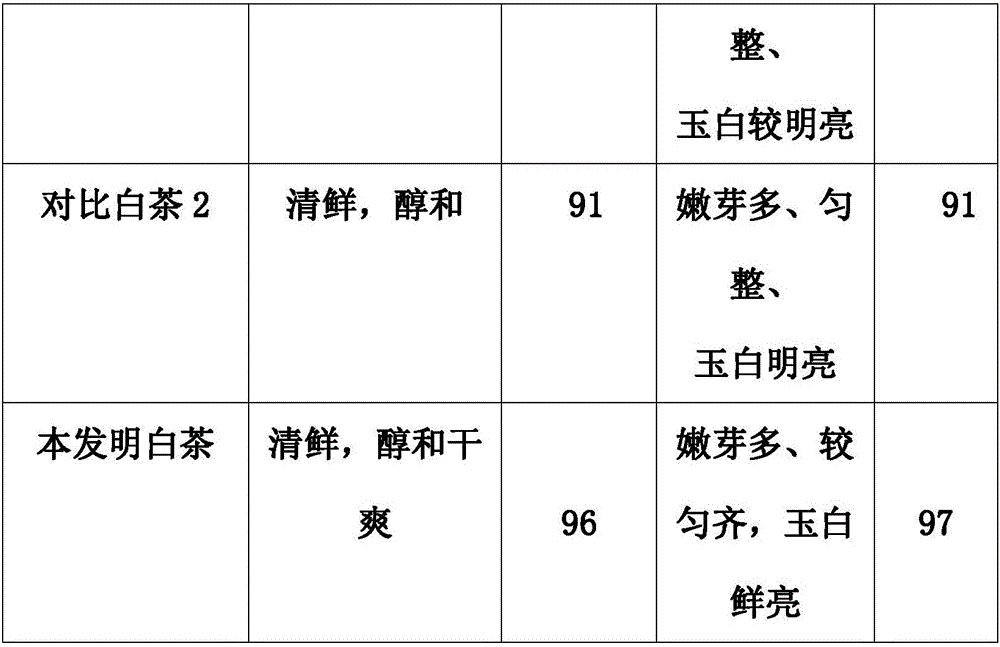

White tea processing technology

The invention provides a white tea processing technology, which specifically includes raw material selection, withering, fermentation, impurity removal, drying and packaging. The white tea produced is of good quality, with high content of amino acids, tea polyphenols, catechins and water extracts. And the cord is flat, green and golden yellow, fresh, soup color, bright color, floral fragrance is obviously slightly sweet, rich and mellow and dry.

Owner:遵义凤龙茶业有限公司

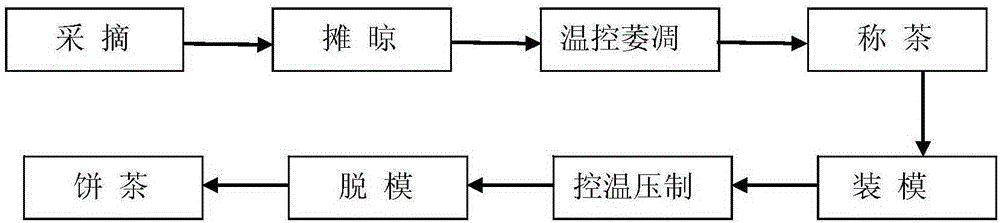

Method for processing white tea cake tea by using lingyun pekoe tea

InactiveCN105192147ALess investmentCutting costsPre-extraction tea treatmentTemperature controlFlavor

The invention relates to a method for processing white tea cake tea by using lingyun pekoe tea, and belongs to the white tea processing field. The method adopts a temperature-control withering technology of firstly heating up and then cooling and a compressed tea steaming-free production technology and comprises the steps: firstly, carrying out temperature control withering on picked lingyun pekoe tea fresh leaves in the temperature range of 20-25 DEG C in a manner of firstly heating up and then cooling, then directly weighing the tea and loading in a molding machine mold, heating up until the temperature of the molding machine mold reaches 80-100 DEG C, applying with the pressure of 10-20 MPa and pressing for 3-5 min, molding, and then demolding to obtain the product. The quality of the prepared lingyun pekoe tea cake tea has no significant difference from tea in bulk, cake blocks are compact and smooth, pekoe is revealed, the color and luster are fresh bright, the flower fragrance is obviously slightly fragrant and sweet, the liquid color is apricot yellow and bright, the flavor is strong, mellow, fresh and brisk, and the cake tea is rich in white tea flavor characteristics.

Owner:广西乐业县昌伦茶叶有限责任公司

Low sugar black tea flavor tea oil mooncake and preparation method thereof

InactiveCN106417496AHigh nutritional valueFull shapeDough treatmentModified nutritive productsNutritive valuesCooking & baking

The invention provides a low sugar black tea flavor tea oil mooncake and a preparation method thereof, and belongs to the food processing field. The preparation method of the low sugar black tea flavor tea oil mooncake includes the specific process steps of raw auxiliary material weighing, preprocessing, cake crust preparation, crust dividing, stuffing filling, shaping, baking, cooling and packaging. The low sugar black tea flavor tea oil mooncake is high in nutritive value, and rich in multiple amino acids, and contains multiple functional factors of tea polyphenol and the like. By adopting a low sugar formula, the low sugar black tea flavor tea oil mooncake overcomes the defects that traditional mooncakes are high in sugar content, soil content and heat, agreeable in sweetness, and nutrient and healthy. Fructo-oligosaccharide is added as prebiotics, can promote propagation of in-vivo Bifidobacterium, and further has multiple healthcare effects of preventing caries and the like. Tea oil is added, rich in unsaturated fatty acid, and difficult to oxidize in high temperature baking, and has multiple healthcare functions.

Owner:ZHANGZHOU COLLEGE OF SCI & TECH

Method for preparing white tea

InactiveCN103689142AAnti-cancerWith heatstrokePre-extraction tea treatmentCancer preventionCooking & baking

The invention relates to a method for preparing white tea. The method comprises the following steps: collecting, spreading, de-enzyming, sorting tea leaves, baking, refining, packaging and storing. The white tea with elaboration has the effects of cancer prevention, cancer treatment, sunstroke prevention, detoxication, toothache treatment and the like, and the white tea prepared by using the method is bright and green in color, good in taste, gentle, moist, long-lasting in fragrance, and good in taste for tea tasters has the obvious flower fragrance, is capable of sinking down once being flushed with water, and can be brewed for a long time.

Owner:程力

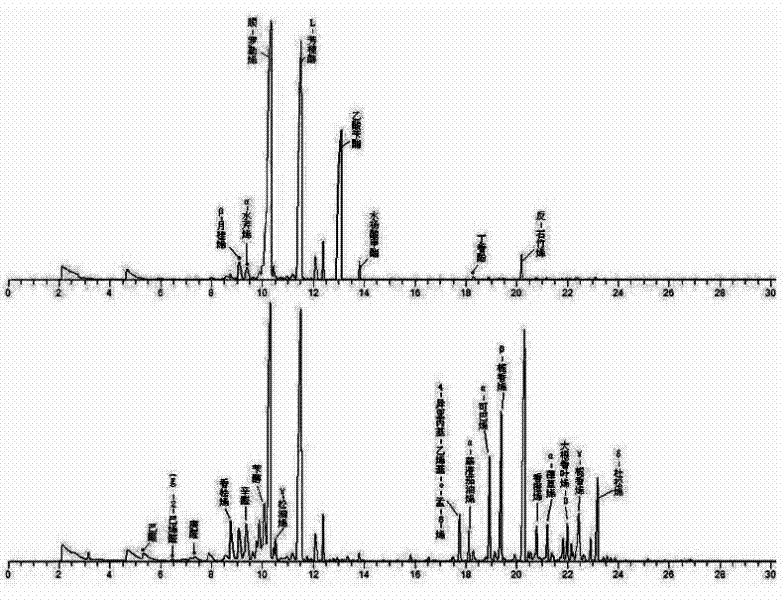

Preparation method of meratia praecox extract for improving aroma and application thereof

InactiveCN102344853AGood sensory evaluationFloral fragranceCosmetic preparationsToilet preparationsChemistryFlavor

The invention discloses a preparation method of meratia praecox extract for improving aroma and application thereof, and belongs to the technical field of perfume preparation. The method comprises the following steps of: adding meratia praecox fresh flower into disodium hydrogen phosphate-nitric acid buffer solution; sterilizing; cooling; adding glucoside lytic enzyme; placing in a vapor bathing constant temperature vibrator for enzymolysis; heating to deactivate enzyme; cooling; separating meratia praecox through centrifugal separation or filtration to obtain clear meratia praecox extract; then concentrating the clear meratia praecox extract under reduced pressure, concentrating the clear meratia praecox extract through a reverse osmosis membrane or performing freezing concentration to obtain meratia praecox raw material concentrate; or treating the clear meratia praecox extract through a steam distillation method, a solvent extraction method, a membrane concentration method, a resin adsorption method, a supercritical extraction method or a reduced pressure concentration method to prepare the meratia praecox extract. The meratia praecox extract, meratia praecox raw material concentrate or aroma concentrate product prepared by the method has sufficient and strong flower aroma; and both intensity and richness of the aroma exceed those of the conventional product.

Owner:JIANGNAN UNIV

Pure manual preparation method of Shuchazao green tea

The invention belongs to the field of foods and in particular relates to a pure manual preparation method of Shuchazao green tea. The method comprises the following steps: picking, fixing, twisting and forming, drying and performing secondary drying. The Shuchazao green tea processed by the process has special effects on aging resistance, cancer prevention, cancer resistance, sterilization and inflammation diminishment. Moreover, the green tea produced by the method is bright and green in tea color, excellent in taste, gentle and soft, has obvious flowery flavor, is resistant to brewing and brings comfortable taste to tea tasters.

Owner:ANHUI HUOSHAN COUNTY JUYI TECH

Paeonia suffruticosa edible candy block and preparation method thereof

InactiveCN105076636AIncrease nutritionGreat tasteConfectionerySweetmeatsPaeonia suffruticosaAdditive ingredient

The present invention relates to a paeonia suffruticosa edible candy block and a preparation method thereof. The paeonia suffruticosa edible candy block uses paeonia suffruticosa petals and paeonia suffruticosa pollen extract. The paeonia suffruticosa pollen nutrient solution, glucose, starch and other raw materials are mixed, and the mixture is subjected to mechanical processing method and to be prepared into the edible candy block. The method effectively preserves a variety of nutrients in the paeonia suffruticosa petals, and the paeonia suffruticosa edible candy block is mellow in fruity taste and is rich in nutrition.

Owner:HENAN LUOYANG RED PEONY IND RES & DEV CO LTD

Nanometer material mould-proof formaldehyde-removing environment-friendly coating and preparation method thereof

InactiveCN107216797AReactiveTo achieve the purpose of purifying the airAntifouling/underwater paintsPaints with biocidesWaxAdjuvant

The invention discloses a nanometer material mould-proof formaldehyde-removing environment-friendly coating. The coating is prepared from the following raw materials in parts by weight: 4 to 6 parts of formaldehyde absorbing agent, 10 to 16 parts of formaldehyde-removing filler, 8 to 14 parts of effective adjuvant, 9 to 15 parts of nanometer material, 2 to 4 parts of silane coupling agent, 28 to 36 parts of high-molecular polymer, 0.2 to 0.8 part of petal extracting solution, 2 to 4 parts of lubrication-increasing water mist-proof wax powder and 7 to 9 parts of organic solvent. The coating disclosed by the invention has an excellent formaldehyde-removing and air-purifying performance, is relatively good in a mould-proof and sterilizing performance, and poisonless and harmless, has the fragrance of flower, and is relatively excellent in a caking property and surface flatness; meanwhile, raw material components of the coating are safe and reliable, healthy and harmless to human bodies, the raw materials are available, the cost is relatively low, and the process is simple. Therefore, the coating has relatively high practical value and a good application prospect.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

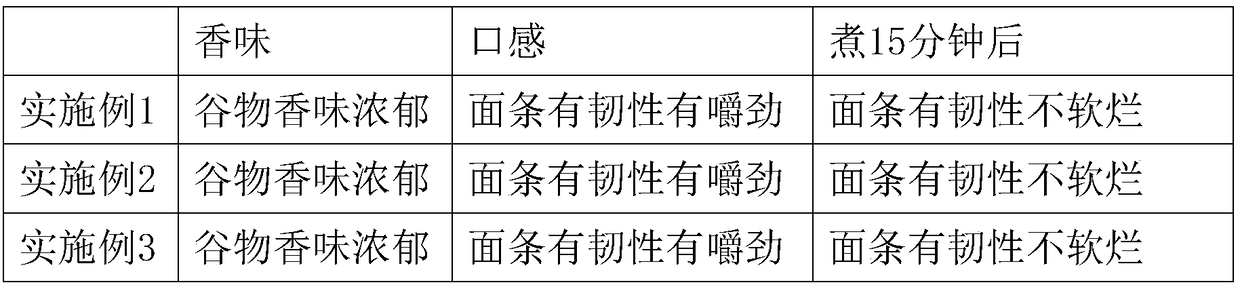

Non-fried highland barley noodle

InactiveCN108967886AAdd flavorUnique flavorFood ingredient as antioxidantFood ingredient as taste affecting agentAdditive ingredientAntioxidant

The invention relates to a non-fried highland barley noodle. In the invention, only wheat flour and eggs are used as main raw materials and are mixed with highland barley flour, so that the flavor ofhighland barley is added while nutrient elements, such as various microelements, vitamins and dietary fibers, are added; potatoes, beans, brown rice, oat and corn kernels are added, so that the potatoes and beans as well as cereals are added for increasing the ingestion of human body to cereals, balancing nutrition and supplementing various microelements and dietary fibers; compared with the chemical components, such as preservatives, added into the traditional instant noodles, the antioxidants extracted from lemon peel and shaddock peel are added, so that the non-fried highland barley noodlehas natural and healthy ingredient sources and has unique flavor and rich nutrition.

Owner:安徽康乐食品科技有限公司

Peony dumplings and preparation method thereof

InactiveCN105010898AIncrease nutritionGreat tasteFood ingredient as taste affecting agentFood ingredient as flavour affecting agentPetalNutrient solution

The invention relates to peony dumplings and a preparation method thereof. The nutrition, the mouth feel, the taste and the flower fragrance of the peony dumplings disclosed by the invention are better than those of other conventional dumplings, and the peony dumplings have the functions of being fragrant and sweet, promoting blood circulation, maintaining beauty and keeping young. The peony dumplings comprise outer wrappers and filling, wherein the outer wrappers consist of 75-90% of flour, 0.2-0.8% of peony seed oil, 1.5-3% of peony pigments, 3-10% of a peony powder nutrient solution and 5-15% of a peony petal extracting solution. The peony dumplings not only maintain original fragrant, sweet and fresh flavors of conventional dumplings but also balance nutrients, and have a better health-care effect on human bodies when being eaten.

Owner:HENAN LUOYANG RED PEONY IND RES & DEV CO LTD

Method for producing chloranthus tea

The invention provides a method for producing chloranthus tea. The method comprises the following steps: treatment of tea base, picking of fresh flowers, treatment of fresh flowers, scenting, as well as packaging, sterilization and warehousing. The invention provides the method for producing jasmine tea with energy saving, high efficiency, and lower production cost. The chloranthus tea obtained by the steps has the advantages of heavy fragrance of flowers, and refreshed mouthfeel.

Owner:青岛益邦瑞达生物科技有限公司

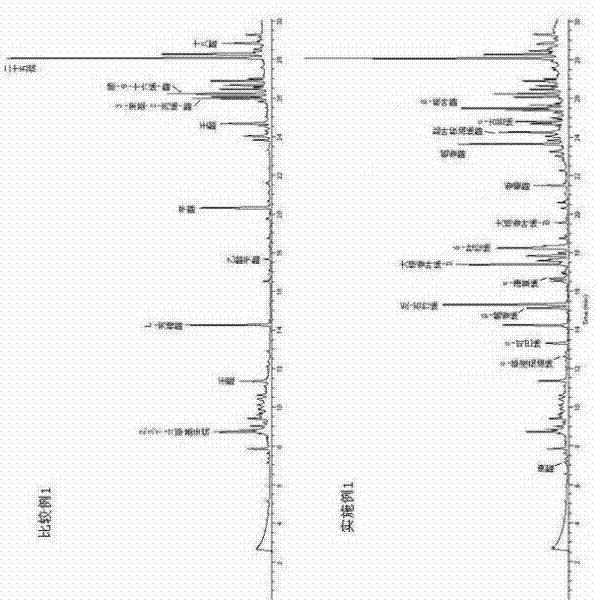

Green tea processing technology

InactiveCN107821661ASolve the problem of low taste and astringencySoft leavesPre-extraction tea treatmentFlavorMicrowave

The invention relates to a processing technology of tea, in particular to a processing technology of green tea. The process includes the following steps: (1) picking fresh leaves; (2) spreading to dry; (3) sun-drying; (4) fixing; (5) kneading; (6) drying. Compared with the traditional green tea processing method, the present invention breaks through the traditional green tea processing, and only performs a short-term air-drying process before finishing. During the drying process, the fresh leaves lose part of the water under the action of light and heat, and the leaf quality becomes soft, which is suitable for subsequent shaking. It can also avoid the burnt smell caused by excessive drum fixing, and it is easier to exert the floral fragrance formed by the tea itself. The final product has a rich and long-lasting floral fragrance, bright apricot-green soup, and a mellow and sweet taste, which solves the problem of low-flavor and astringent taste of middle and low-grade green tea, greatly improves its sensory quality, and significantly improves economic benefits.

Owner:杨小会

Processing technology of floral type Tieguanyin green tea

InactiveCN110292077AImprove efficiencyPromote transformation synthesisPre-extraction tea treatmentSweetnessCell budding

The invention provides a processing technology of floral type Tieguanyin green tea. The processing technology comprises the following steps of picking (small and tender tea leaves with 1 bud and 2-3 leaves are picked), spreading and drying (the tea leaves are spread on a bamboo sieve with thickness of 2-5 centimeters for 1 hour or above), rocking (slight rocking is performed for 30-12 seconds through a rocking machine), withering (the tea leaves are spread on the bamboo sieve with thickness of 2-5 centimeters for 6 hour or above), fixation (fixation is performed for 2-5 minutes at the pot temperature of 220-280 DEG C), rolling (rolling is performed for 25-45 minutes, and deblocking is carried out), primary stir-drying (the tea leaves are stir-dried to 50-60% dryness at the pot temperatureof 160-200 DEG C, and spreading for cooling is carried out), secondary stir-drying (the tea leaves are stir-dried for 1 hour or above at the pot temperature of 60-75 DEG C) and fragment enhancing (thetea leaves are stir-dried for 5-15 minutes at the pot temperature of 85-125 DEG C). The processing technology of the floral type Tieguanyin green tea fills the technical blank of an existing Tieguanyin variety suitable for making green tea, the prepared product has high aroma, obvious floral scent, thick and mellow taste, sweetness after drinking, bright green or bright yellow green soup color and light green leaf bottom, the quality reaches the middle and high-end green tea level, the yield is relatively increased, and the comprehensive benefits of the Tieguanyin variety are improved.

Owner:钟德民

Health care scented tea, and preparation method thereof

InactiveCN105475564AFloral fragranceReasonable collocationTea substituesNutritive valuesLilium brownii

The invention discloses a health care scented tea, and a preparation method thereof, and belongs to the technical field of scented tea. The health care scented tea is composed of, by weight, 30 to 50 parts of folium ginkgo, 7 to 15 parts of Chinese wolfberry, 7 to 15 parts of astragalus membranaceus flower, 7 to 15 parts of flos chrysanthemi, 5 to 11 parts of syringa pubescens flower, 4 to 10 parts of lilium brownii flower, and 10 to 14 parts of flos lonicerae. Raw material combination of the health care scented tea is reasonable; the health care scented tea can be used for replacing traditional tea, is abundant in a plurality of vitamins, mineral substances, and trace elements; a finished product possesses thick flowery flavour; the health care scented tea is capable of reducing blood pressure and blood fat; frequent drinking of the health care scented tea is helpful for losing weight; mouthfeel is excellent; requirements of consumers on health and mouthfeel can be satisfied; the preparation method is simple and reasonable; and nutritional value is high.

Owner:季桂芳

Paeonia suffruticosa rice glue ball and preparation method thereof

InactiveCN105010899AIncrease nutritionGreat tasteFood ingredient as taste affecting agentFood ingredient as flavour affecting agentPaeonia suffruticosaFlavor

The present invention relates to a paeonia suffruticosa rice glue ball and a preparation method thereof. The paeonia suffruticosa rice glue ball is superior to other existing rice glue ball in nutrition, mouthfeel, flavor, and flower fragrance, has functions of sweetening, activating blood, and beautifying features and keeping young, and includes skins and fillings. The skin is made of 75-90% of glutinous rice flour and long-shaped rice flour, 0.2-0.8% of paeonia suffruticosa seed oil, 1.5-3% of paeonia suffruticosa flower pigment, 3-10% of paeonia suffruticosa pollen nutrient solution, and 5-15% of paeonia suffruticosa petal extract. The paeonia suffruticosa rice glue ball not only maintains the original fragrant, sweet, fresh, smooth, and waxy flavor of traditional sweet dumplings without attenuation, but also is nutritionally balanced, and has relative good health-care functions of human body after being consumed.

Owner:HENAN LUOYANG RED PEONY IND RES & DEV CO LTD

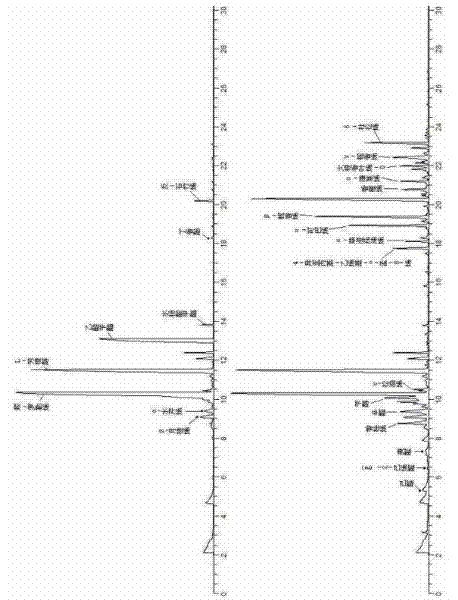

Preparation method of high-procyanidine content blueberry leaf oolong tea

InactiveCN107467231AUniform colorFloral fragrancePre-extraction tea treatmentDry weightGallic acid ester

The invention relates to a preparation method of a high-procyanidine content blueberry leaf oolong tea, and belongs to the technical field of agricultural product deep processing. The method comprises raw material plucking, withering, fine manipulation, enzyme deactivation, wrapping twisting, drying, and screening. The method is characterized by adopting leaves ranking second to sixth on newborn branches of vaccinium ashei fruit trees in July or August as raw materials, adopting the fine manipulation and wrapping-twisting techniques used for an oolong tea to obtain half-fermented blueberry leaves, and adopting a variable frequency microwave low temperature treatment process to reserve active components of the blueberry leaves in the enzyme deactivation process. According to the invention, resource utilization of the blueberry leaves on the branches need pruning is realized. The prepared blueberry leaf oolong tea has a similar brewing effect to a conventional oolong tea. A content of procyanidine which is an active substance is 76.1-138.7 mg catechin equivalent / g by dry weight, and a content of total phenols is 119.4-182.1 mg gallic acid equivalent / g by dry weight.

Owner:JIANGSU ACAD OF AGRI SCI

Special green tea processing method

The invention discloses a special green tea processing method, which comprises the following steps: preparing tea tree purple leaves, cooling, sun-withering, cooling for the second time, greening thegreen tea leaves, removing water, rolling and low-temperature baking to prepare green tea. Part of water is emitted through two times of cooling, leaf toughness is improved, subsequent procedures arefacilitated, meanwhile, enzyme activity is enhanced, bitterness of part of anthocyanin can be eliminated, part of grass smell is emitted, and fragrance permeation is facilitated. And low-temperature baking is performed until the water content is 15-20%, so that the special fragrance flower fragrance and fruity fragrance of the green tea can be retained, and the special fragrance loss of the greentea is reduced. According to the invention, a purple bud leaf product, namely the special green tea, is developed, the purple leaf raw material is fully utilized, the waste of the raw material in summer is avoided, the method has important significance for increasing the income of tea growers and adjusting the structure of the tea industry, and the innovation of the tea industry and health-care industry fusion mode is promoted.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

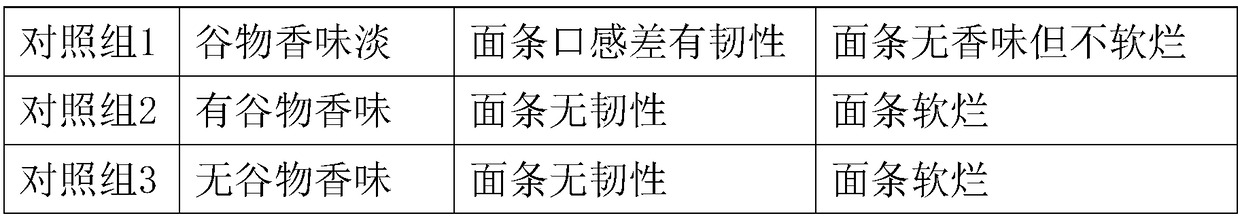

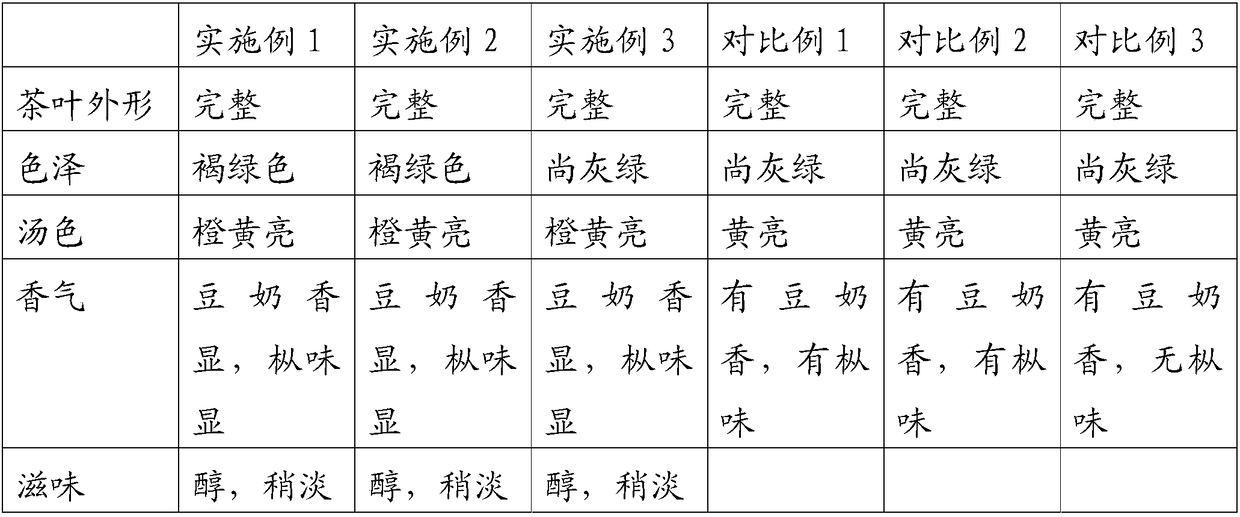

Old-fir-flavored white tea processing method

The invention discloses an old-fir-flavored white tea processing method, and belongs to the technical field of tea leaf processing. The processing method comprises: selecting a high-aroma type tea tree variety planted at an altitude of more than 1000 m or above and having a tree age of 60 years or above, and sequentially carrying out withering, pile fermentation, primary baking, picking and complete drying, wherein the pile fermentation comprises that withered tea leaves are gently stacked, the stacking height is 48-52 cm, and the pile fermentation time is 45-50 h. According to the present invention, with the processing method, the obtained finished product has characteristics of complete tea leaf shape, grayish green or brownish green color, orange and bright soup, significant and lastingsoy milk fragrance, significant fir flavor, mellow and slightly-light taste and brewing resistance, and further has advantages of no plant odor and no astringent taste compared with the product obtained by the traditional production process; the operation of the method is simple, the whole processing process can be controlled manually, and the processing process is independent of the natural environment and is not affected by the natural environment; and the finished product has advantages of good quality and stable quality.

Owner:福建省政和县茗香轩茶厂 +1

Non deep-fried instant noodles having effects of nourishing faces and reducing weight

InactiveCN108936279ARaise the ratioIncrease intakeFood ingredient functionsFlavorChemical composition

The invention relates to non deep-fried instant noodles having effects of nourishing faces and reducing weight. According to the non deep-fried instant noodles disclosed by the invention, only wheat flour, whole wheat flour and eggs are used as main raw materials, and the proportion of the whole wheat flour is increased, so that the fragrance is greatly improved, and various nutrient elements of trace elements, vitamins, dietary fibers and the like are provided; then through cooperation of crucian carps, red beans, pumpkins, oat and peanuts, intake of protein is increased, intake of coarse cereals is increased, various nutrients are balanced, protein, trace elements and dietary fibers are complemented, and the non deep-fried instant noodles are high in nutrient value and low in calorie andhave the efficacy of nourishing faces, expelling toxins and reducing weight; and besides, an antioxidant extracted from lemon peel and pomelo peel is also added, so that compared with traditional instant noodles with chemical components of preservatives and the like, the non deep-fried instant noodles are natural and healthy in component sources, and have unique flavor and rich nutrients.

Owner:安徽康乐食品科技有限公司

A kind of processing method of golden camellia black tea

InactiveCN102987034BSignificant comprehensive benefitsHas a floral qualityTea substituesMicrowaveBlack tea

Owner:GUANGXI FUXIN SCI & TECH

Okra glutinous rice wine and preparation method thereof

InactiveCN103525660BRich in nutrientsRich in water soluble substancesMicroorganism based processesAlcoholic beverage preparationBiotechnologyNutrition

Okra glutinous rice wine is characterized by being prepared through the steps as follows: raw material selection, preparation of an okra flower extracting solution, rice soaking, glutinous rice wine preparation, okra flower extracting solution and glutinous rice compositing, sterilization and the like. The preparation method is simple in production technology and low in cost; and the okra glutinous rice wine is rich in nutriment and soft in flavor, integrates functions such as nutrition, health care, diet therapy and the like, and has a better consumption prospect.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Dragon fruit sparkling wine and preparation method thereof

InactiveCN109055112AFast fermentationFloral fragranceAlcoholic beverage preparationVitis viniferaHyperplasia

The invention discloses dragon fruit sparkling wine. The dragon fruit sparkling wine is prepared from components as follows: 20-40 parts of dragon fruits, 5-15% of grapes, 10-20 parts of dragon fruitflowers and 30-50 parts of glutinous rice. Through a series of process study, grapes with downy mildew are selected and mixed with dragon fruits for fermentation, and the best fermentation process ofthe sparkling wine with high fermentation speed, outstanding flower fragrance, purplish red and bright color, fresh and sweet wine aroma and strong aftertaste is selected. The preparation method of the sparkling wine is simple and the pressure in the sparkling wine can be kept for a long time. The sparkling wine contains multiple vitamins and anthocyanin, has functions of resisting oxidation and aging, softening blood vessels and protecting heart and cerebral vessels and has very good food therapy effects on oral ulcer, eye dryness, skin spot hyperplasia and the like.

Owner:广西海泉农业有限公司

Orchid-shaped black tea making process

InactiveCN102715295BNice appearanceSoup color bright red and yellowPre-extraction tea treatmentCardingBlack tea

The invention relates to an orchid-shaped black tea making process, which comprises the steps of picking, spreading and airing, sunning, fixation, withering, carding, fermentation, first drying, fragrance extraction and the like. Black tea which is processed through the process is flat, straight, graceful and orchid-shaped, the appearance is attractive, the tea soup is reddish yellow and bright, the fragrance is pleasing and the internal quality of excellent.

Owner:句容市张庙茶场有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com