Non-fried highland barley noodle

A highland barley noodle, non-fried technology, applied in the direction of food ingredients as antioxidants, food ingredients as taste improvers, food ingredients as taste improvers, etc. Health and other issues, to achieve unique flavor, increase starch content and protein content, and enrich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

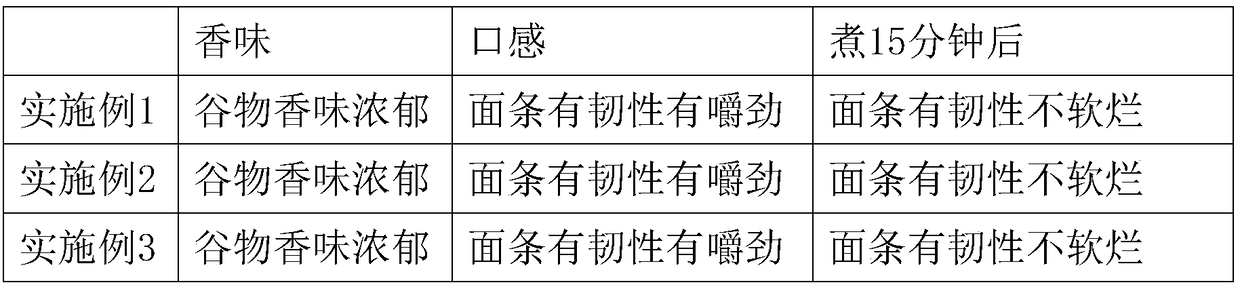

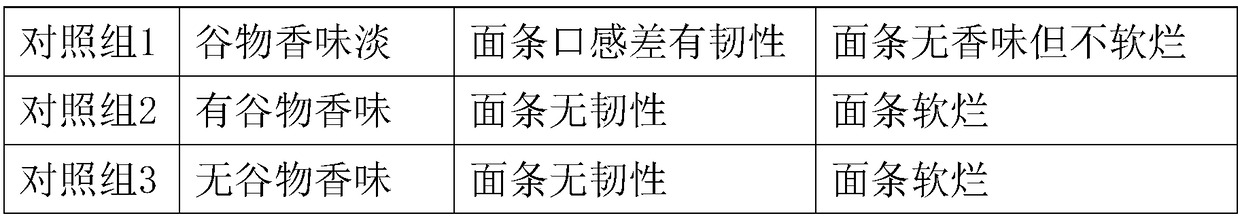

Examples

Embodiment 1

[0033] A non-fried highland barley noodle, characterized in that it consists of the following raw materials in parts by weight: 80 parts of wheat flour, 30 parts of highland barley flour, 5 parts of potatoes, 5 parts of soybeans, 5 parts of brown rice, 5 parts of oats, and 5 parts of corn kernels servings, 3 servings of antioxidants, 10 servings of eggs, 5 servings of edible salt, and 10 servings of coconut oil.

[0034] Further, the antioxidant is extracted from lemon peel and grapefruit peel, and its preparation method is as follows: cut off the white flesh of lemon peel and grapefruit peel, clean them, and put them in a freezer at -20 degrees for 1 hour , crush the juice of the frozen lemon peel and grapefruit peel with a wall breaker, add water and compound enzyme to the mixed juice, and carry out heat preservation and enzymolysis at a temperature of 35°C for 1 hour, and then heat to reflux state and heat preservation and stirring for 10 minutes, Centrifuge, take the enzym...

Embodiment 2

[0052] A non-fried highland barley noodle, characterized in that it consists of the following raw materials in parts by weight: 90 parts of wheat flour, 40 parts of highland barley flour, 8 parts of potatoes, 8 parts of soybeans, 8 parts of brown rice, 8 parts of oats, and 8 parts of corn kernels servings, 5 servings of antioxidants, 13 servings of eggs, 7 servings of edible salt, and 15 servings of coconut oil.

[0053] Further, the antioxidant is extracted from lemon peel and grapefruit peel, and its preparation method is as follows: cut off the white flesh of lemon peel and grapefruit peel, clean them, and put them in a freezer at -20 degrees for 1.5 hours of freezing , crush the juice of the frozen lemon peel and grapefruit peel with a wall breaker, add water and compound enzyme to the mixed juice, and carry out heat preservation and enzymolysis at a temperature of 40°C for 1.5 hours, and then heat to reflux state and heat preservation and stirring for 13 minutes, Centrifu...

Embodiment 3

[0071] A non-fried highland barley noodle, characterized in that it consists of the following raw materials in parts by weight: 100 parts of wheat flour, 50 parts of highland barley flour, 10 parts of potatoes, 10 parts of soybeans, 10 parts of brown rice, 10 parts of oats, and 10 parts of corn kernels servings, 6 servings of antioxidants, 15 servings of eggs, 10 servings of edible salt, and 20 servings of coconut oil.

[0072] Further, the antioxidant is extracted from lemon peel and grapefruit peel, and its preparation method is as follows: cut off the white pulp of lemon peel and grapefruit peel, clean them, and put them in a freezer at -20 degrees for 2 hours , crush the juice of frozen lemon peel and grapefruit peel with a wall breaker, add water and compound enzyme to the mixed juice, and carry out heat preservation and enzymolysis at a temperature of 45°C for 2 hours, and then heat to reflux state and heat preservation and stirring for 15 minutes. Centrifuge, take the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com