Old-fir-flavored white tea processing method

A processing method and technology of white tea, which is applied in the processing field of Laocong-flavored white tea, can solve the problems affecting the taste of Laocong, difficult to control, changeable environment, etc., and achieve the effect of good quality, stable quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

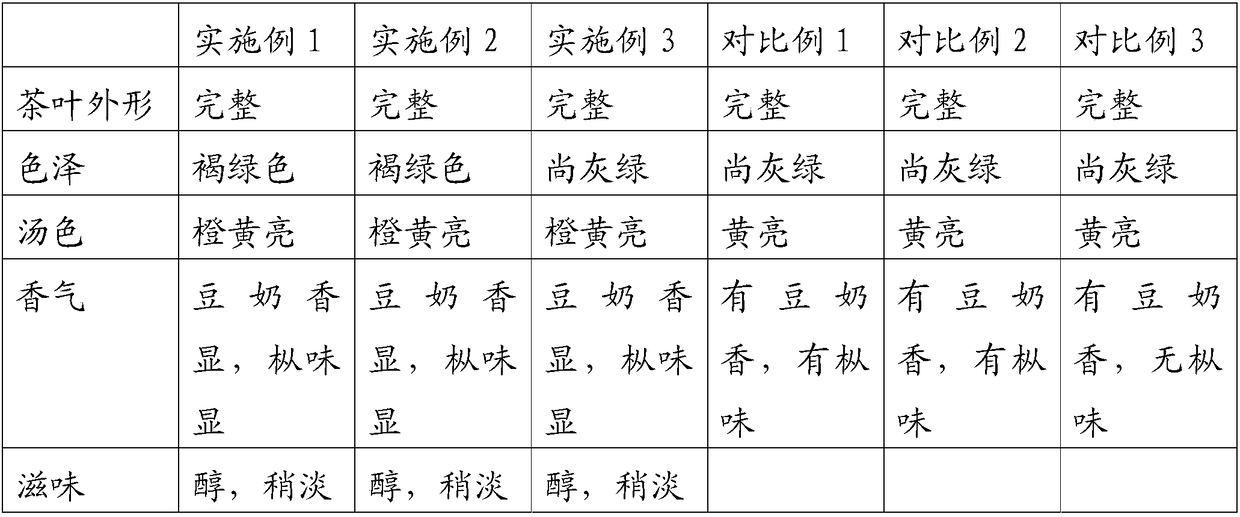

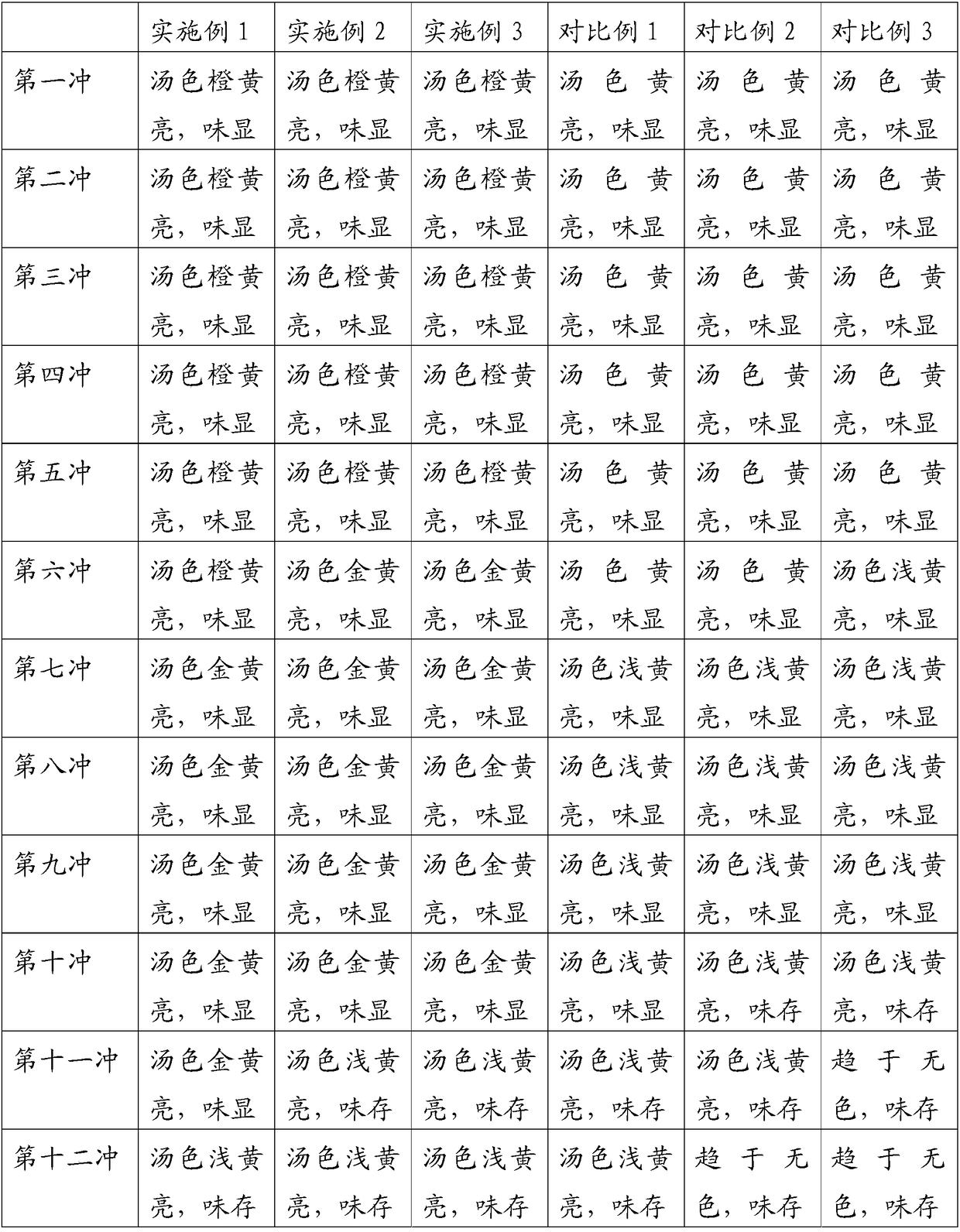

Examples

Embodiment 1

[0032] The processing method of Laocong flavor white tea comprises the following steps:

[0033] (1) Raw materials: choose Meizhan tea trees planted at an altitude of more than 1000 meters and more than 60 years old, and pick the new shoots with one bud and five or six leaves that grow robustly in the current round in mid-August as raw materials;

[0034] (2) withering trough withering: the relative humidity of the withering workshop is controlled at 90%, the workshop keeps the exhaust fan for continuous exhaust ventilation, and the fresh leaves enter the withering trough and spread out, and the thickness of the spread leaves is 15cm; blowing air for 8h earlier, and leaving standstill for 10h; Continuous blowing for 16 hours and standing for 8 hours; then blowing for 16 hours, and then standing for 8 hours until the withered leaves are 80% dry; if the temperature exceeds 35°C during the standing process, the withered leaves need to be turned once; the blowing temperature is 25...

Embodiment 2

[0040] The processing method of Laocong flavor white tea comprises the following steps:

[0041] (1) Raw materials: select Tianshan vegetable tea trees planted at an altitude of more than 1,000 meters and are more than 60 years old, and pick their vigorously growing new shoots with one bud and five or six leaves in mid-August as raw materials;

[0042] (2) withering trough withering: the relative humidity of the withering workshop is controlled at 80%, the workshop keeps the exhaust fan for continuous exhaust ventilation, and the fresh leaves enter the withering trough and spread out, and the thickness of the spread leaves is 16cm; blowing air for 8h earlier, and leaving standstill for 10h; Continue to blow air for 16 hours and let it stand for 8 hours; then blow it for 16 hours, and then let it stand for 7 hours until the withered leaves are 70% dry; if the temperature exceeds 35°C during the standing process, you need to turn the withered leaves once; the temperature of the b...

Embodiment 3

[0048] The processing method of Laocong flavor white tea comprises the following steps:

[0049] (1) Raw materials: choose Zhenghe Caicha tea trees planted at an altitude of more than 1000 meters and more than 60 years old, and pick their vigorously growing new shoots with one bud and five or six leaves in mid-August as raw materials;

[0050] (2) withering tank withering: the relative humidity of the withering workshop is controlled at 85%, the workshop keeps the exhaust fan for continuous exhaust ventilation, and the fresh leaves enter the withering tank and spread out, and the thickness of the spread leaves is 13cm; blowing air for 8h earlier, and leaving standstill for 10h; Continuous blowing for 16 hours, standing for 8 hours; then blowing for 16 hours, and then standing for 9 hours until the withered leaves are 80% dry; the blowing temperature is 25°C-26°C;

[0051] (3) Wort heap: the withered leaves are piled together gently, the leaf height is 48cm, and the wort heap t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com