Orchid-shaped black tea making process

A production process and technology for black tea, applied in the field of production technology of orchid-shaped black tea, can solve the problem that it is difficult to make a famous green tea with a beautiful shape, low requirements for the shape and leaf bottom, and achieve a beautiful appearance, prominent floral fragrance, and bright red and yellow soup color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

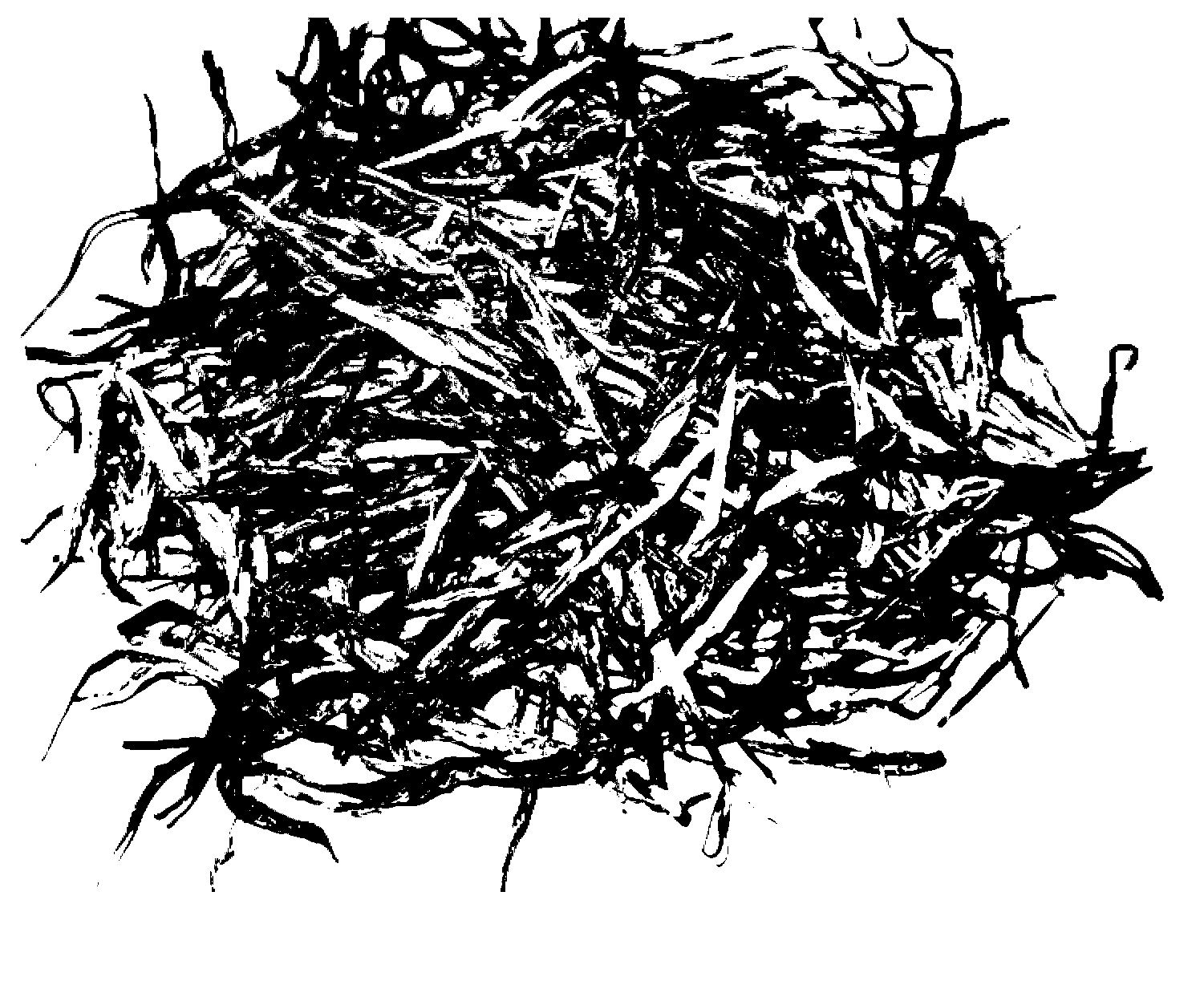

Image

Examples

Embodiment 1

[0021] A kind of manufacture craft of orchid-shaped black tea, it comprises the steps:

[0022] (1) Picking. The standard is 1 bud, 1 and 2 leaves, and leaves with diseased insects, dew leaves and rain leaves are not collected.

[0023] (2) Spread to dry. The picked fresh leaf raw materials are placed indoors to cool down in the air. The temperature in the airing room is kept at 15-22°C, and the thickness of the airing leaves is 5-10cm. Airing until the temperature of the fresh leaves uniformly drops to room temperature, so that the greening can be evenly dried.

[0024] (3) Dry green. Thinly spread the fresh leaves to dry green, the thickness of the spread leaves is less than 1cm, the temperature for drying green is 22-28°C, and the drying time is 15-30min. The degree of sun-drying is based on the green air, the leaves are wilted, the terminal buds and the first leaves are slightly drooping, and the weight loss rate of fresh leaves is 8-15%.

[0025] (4) Make green. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com