Process for preparing proton composite exchange membrane for high temperature proton exchange membrane fuel battery

A proton exchange membrane and fuel cell technology, which is used in the field of preparation of proton exchange membrane composite membranes, can solve the problem that proton exchange membranes cannot work effectively at high temperatures, and achieve strong water absorption and water retention capabilities, large surface area, high water absorption and The effect of water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

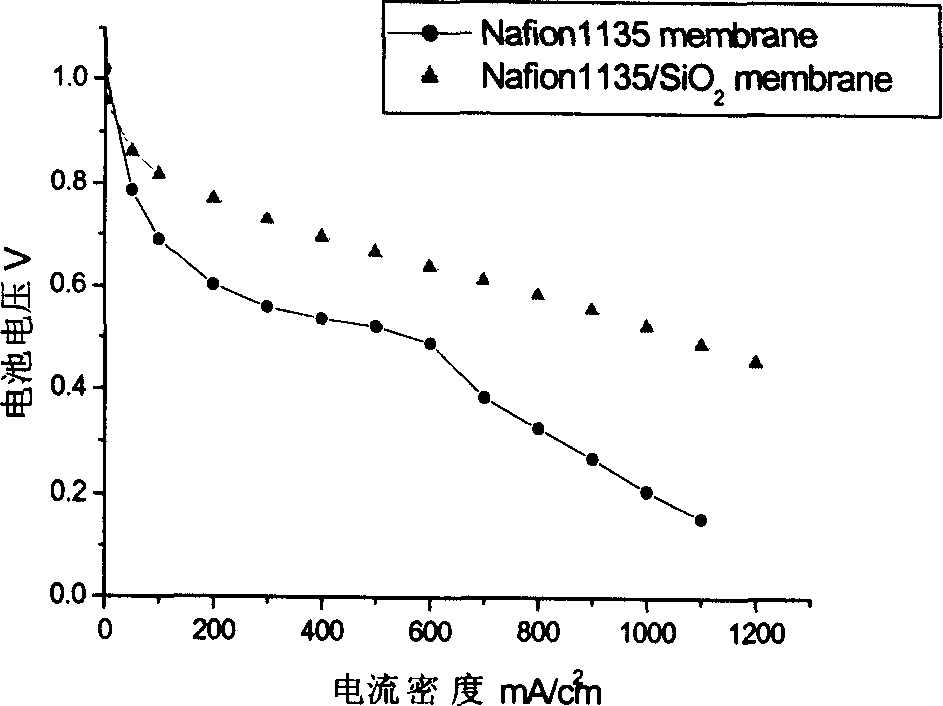

[0021] Embodiment 1: Cut a piece of Nafion1135 film of 6cm * 6cm, then Nafion1135 film is immersed in the mixed solution of tetraethyl orthosilicate and ethanol that volume ratio is 3: 2, after stirring for 1 minute, this solution is sealed and placed, 12 Take the Nafion1135 membrane out of the sealing solution after 1 hour, blot the solution on the surface of the membrane with filter paper, then immerse it in a mixed solution of ethanol and water with a volume ratio of 2:1, take the membrane out and put it in a vacuum drying oven after 5 minutes Dry at 100°C for 12 hours to get Nafion\SiO 2 composite film. Then Nafion\SiO 2 The composite membrane was put into 3% hydrogen peroxide solution, deionized water, 0.5M sulfuric acid solution, and deionized water in sequence, boiled for 1 hour each, and then placed in deionized water for standby. The conductivity test results are shown in Table 1.

Embodiment 2

[0022] Example 2: Cut a piece of Nafion1135 film of 6cm × 6cm, then immerse the Nafion1135 film in a mixed solution of tetraethyl orthosilicate and ethanol with a volume ratio of 1:3, stir for 1 minute, and place the solution in a sealed place for 10 hours Finally, take the Nafion1135 membrane out of the sealing solution, blot the solution on the surface of the membrane with filter paper, and then immerse it in a mixed solution of ethanol and water with a volume ratio of 1:1. After 10 minutes, take the membrane out and put it in a vacuum drying oven. Dry at 100°C for 24 hours to get Nafion\SiO 2 composite film. Then Nafion\SiO 2 The composite membrane was put into 3% hydrogen peroxide solution, deionized water, 0.5M sulfuric acid solution, and deionized water in sequence, boiled for 1 hour each, and then placed in deionized water for standby. The conductivity test results are shown in Table 1.

[0023] The gas diffusion electrode was prepared by using carbon paper, polytetr...

Embodiment 3

[0026] Example 3: Cut a 6cm×6cm Nafion117 film, then immerse the Nafion117 film in a mixed solution of butyl titanate and methanol with a volume ratio of 2:1, stir for 1 minute, and place the solution in a sealed place, after 12 hours Take the Nafion117 membrane out of the sealing solution, blot the solution on the surface of the membrane with filter paper, and then immerse it in a mixed solution of methanol and water with a volume ratio of 3:2. After 10 minutes, take out the membrane and put it in a vacuum drying oven at 100 ℃ for 12 hours to get Nafion\TiO 2 composite film. Then put Nafion\TiO 2 The composite membrane was put into 3% hydrogen peroxide solution, deionized water, 0.5M sulfuric acid solution, and deionized water in sequence, boiled for 1 hour each, and then placed in deionized water for standby.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com