Patents

Literature

49results about How to "Affects structural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

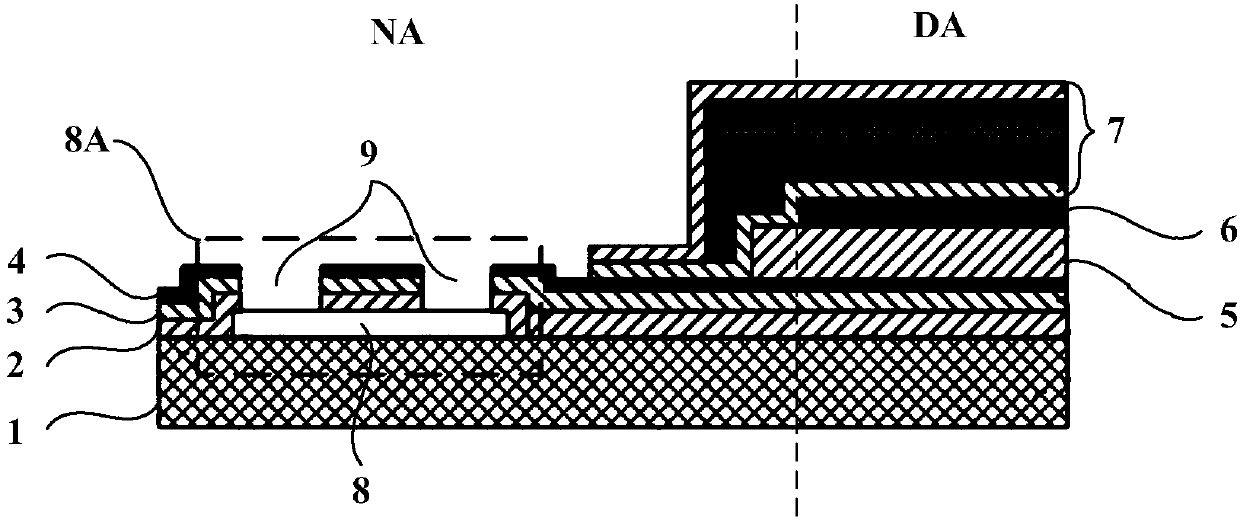

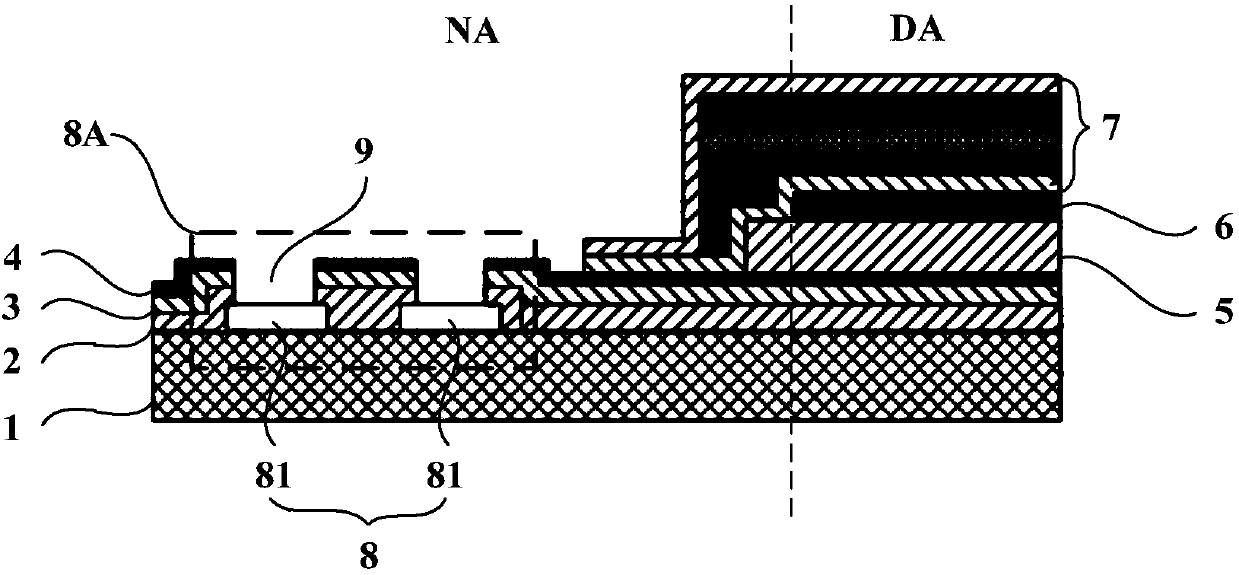

Flexible display panel and manufacturing method thereof

ActiveCN107910349AImprove yield rateAffect displaySolid-state devicesSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a flexible display panel and a manufacturing method thereof so that the possibility of excessive etching in groove hole etching in a non-display area of a flexible display panel can be reduced and thus the etching precision is improved and the yield of the flexible display panel is enhanced. The flexible display panel is composed of a flexible substrate, a buffer layer, a gate insulating layer, an interlayer dielectric layer, a thin-film transistor, an organic electroluminescence element, and an encapsulation layer. The flexible substrate consists of a display area anda non-display area. An etching stop layer is arranged at the display area of the flexible substrate; and the buffer layer, the gate insulating layer, and the interlayer dielectric layer are arranged on the flexible substrate and the etching stop layer successively. At least one etched groove hole is formed in a region, corresponding to the etching stop layer, of each of the buffer layer, the gateinsulating layer, and the interlayer dielectric layer in the non-display area respectively. And the thin-film transistor, the organic electroluminescence element, and the encapsulation layer are arranged on the interlayer dielectric layer in the display area successively.

Owner:BOE TECH GRP CO LTD

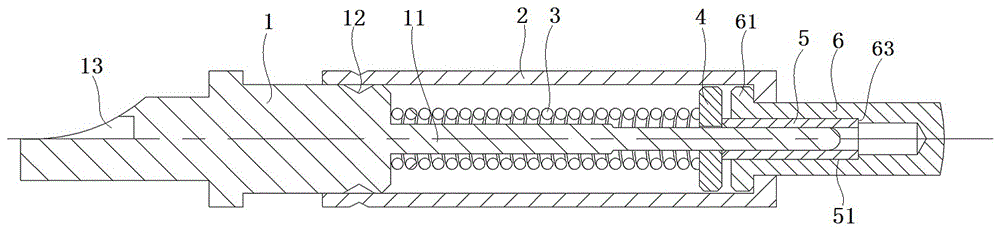

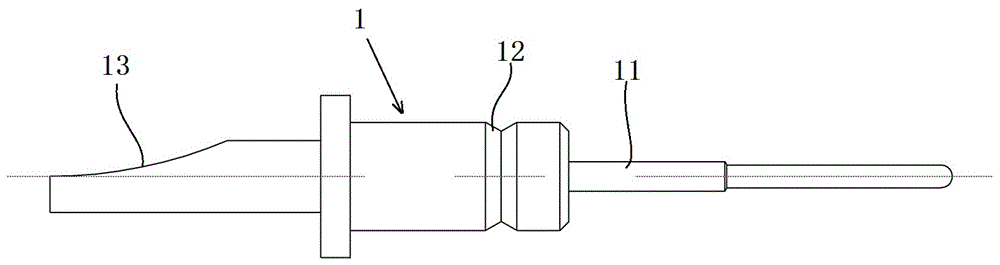

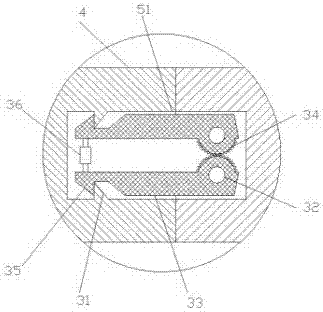

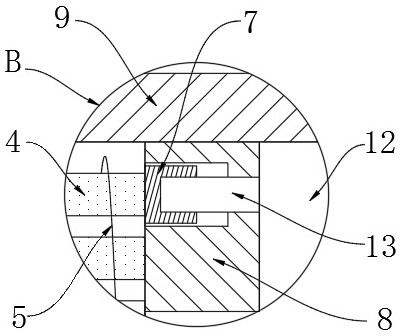

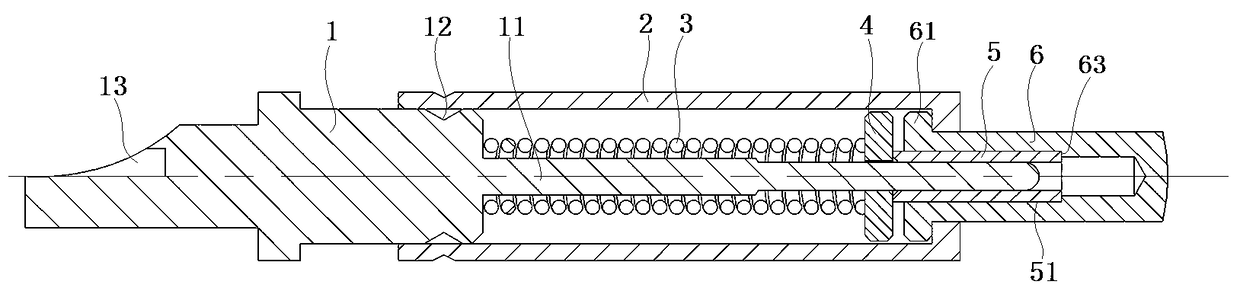

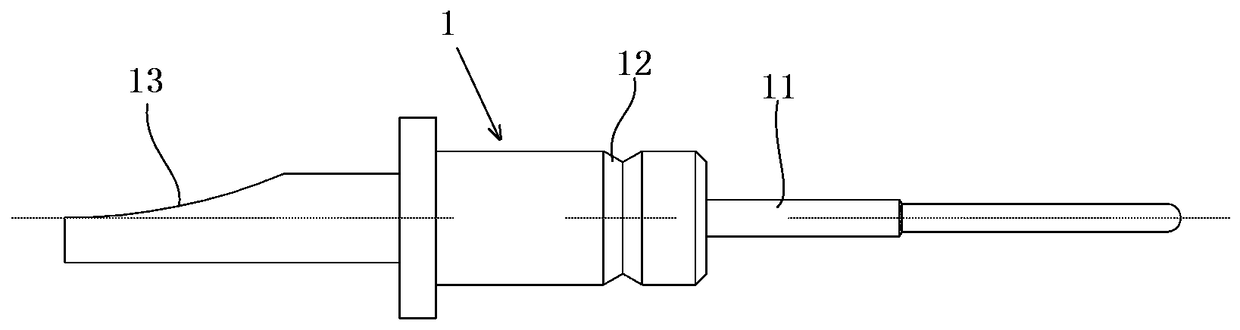

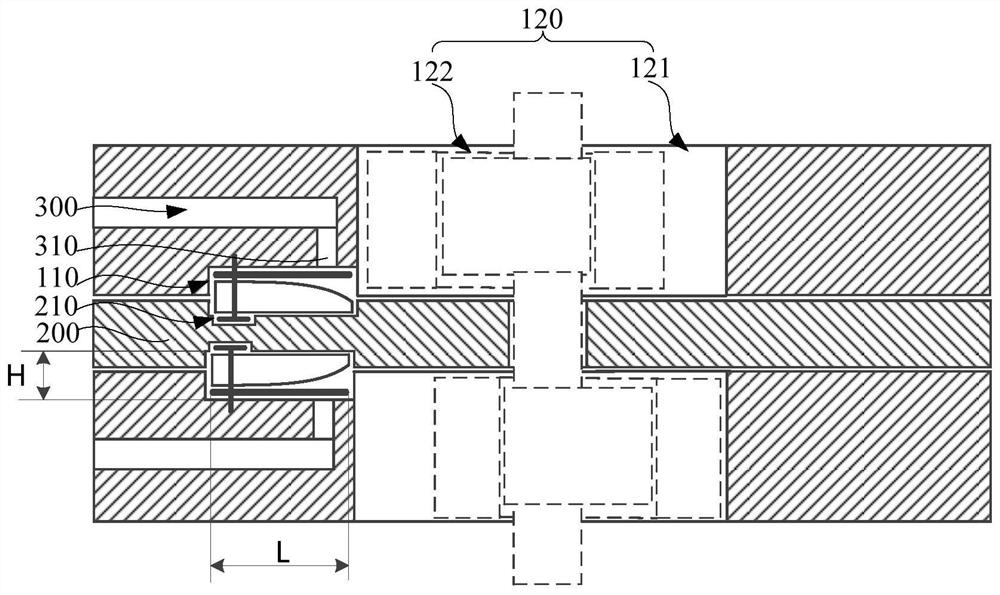

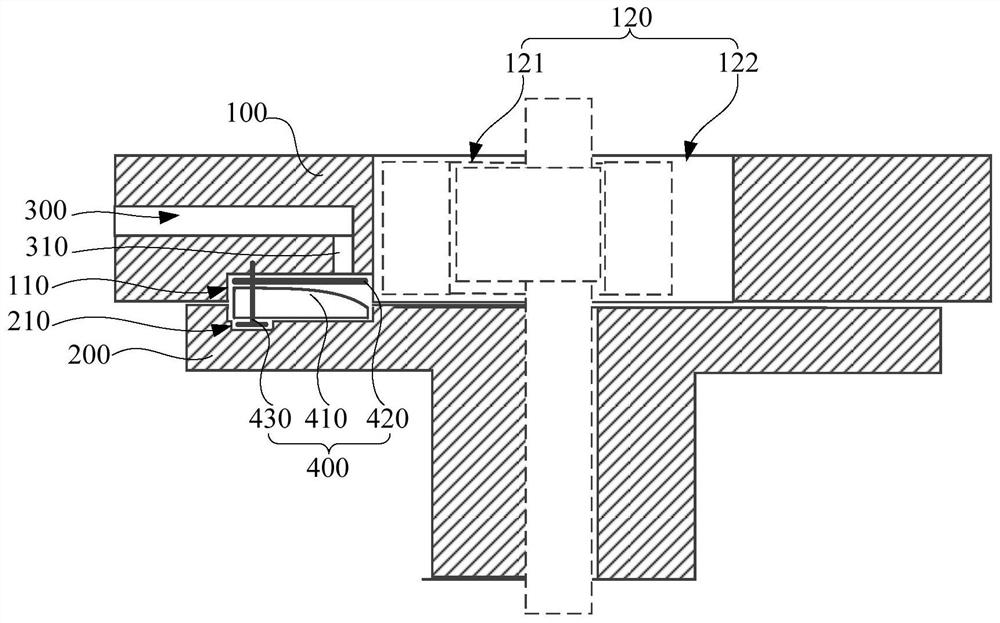

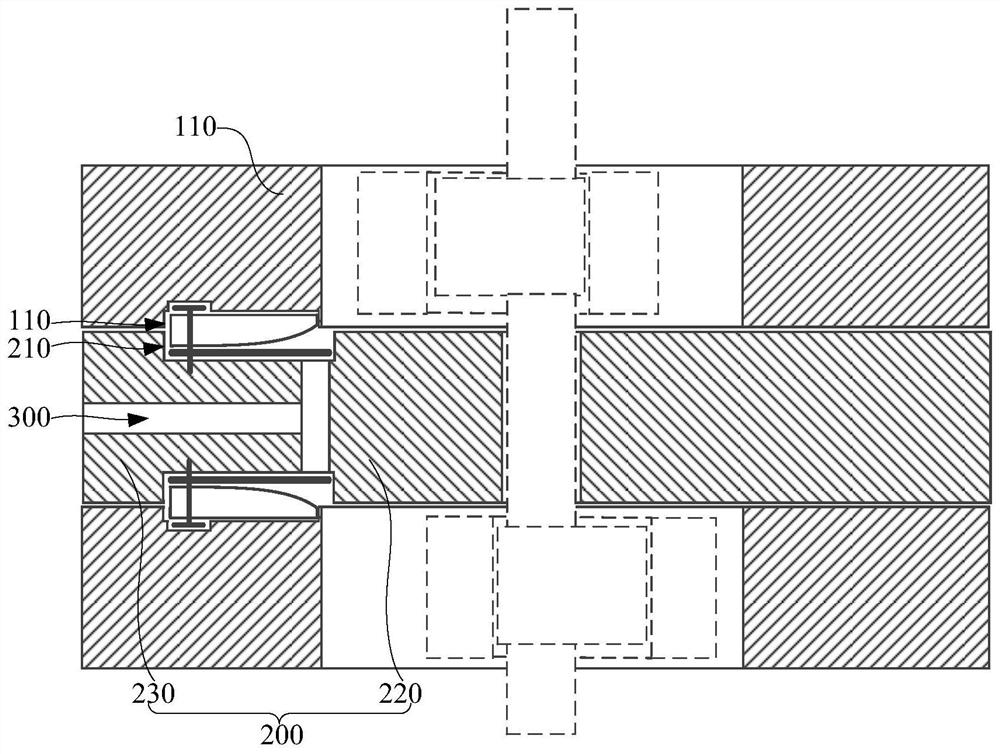

Elastic contact part and electric connector employing same

ActiveCN106025629AFit tightlyImprove reliabilityCoupling contact membersElectrical conductorSliding contact

The invention relates to the field of electric connectors, in particular to an elastic contact part and an electric connector employing the same. The elastic contact part comprises a tail conductor, a contact part and an elastic part, wherein the elastic part is used for providing the contact part with elastic force; a contact pin extending along the axial direction is arranged at the front end of the tail conductor; the contact part comprises a contact part body; a contact end is arranged at the front end of the contact part body; a shrinking structure capable of extending along the axial direction of the contact pin and elastically shrinking along the radial direction of the contact pin is arranged at the rear part of the contact part body; and the shrinking structure and the contact pin are in elastic sliding contact. The contact pin extending along the axial direction is arranged at the front end of the tail conductor; and the shrinking structure capable of shrinking along the radial direction of the contact pin is arranged at the rear end of the contact part body; and the contact part sleeves the contact pin through the shrinking structure on the contact part body, so that the contact part and the contact pin are tightly laminated; and the electric connection reliability between the contact part and the contact pin is strengthened.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

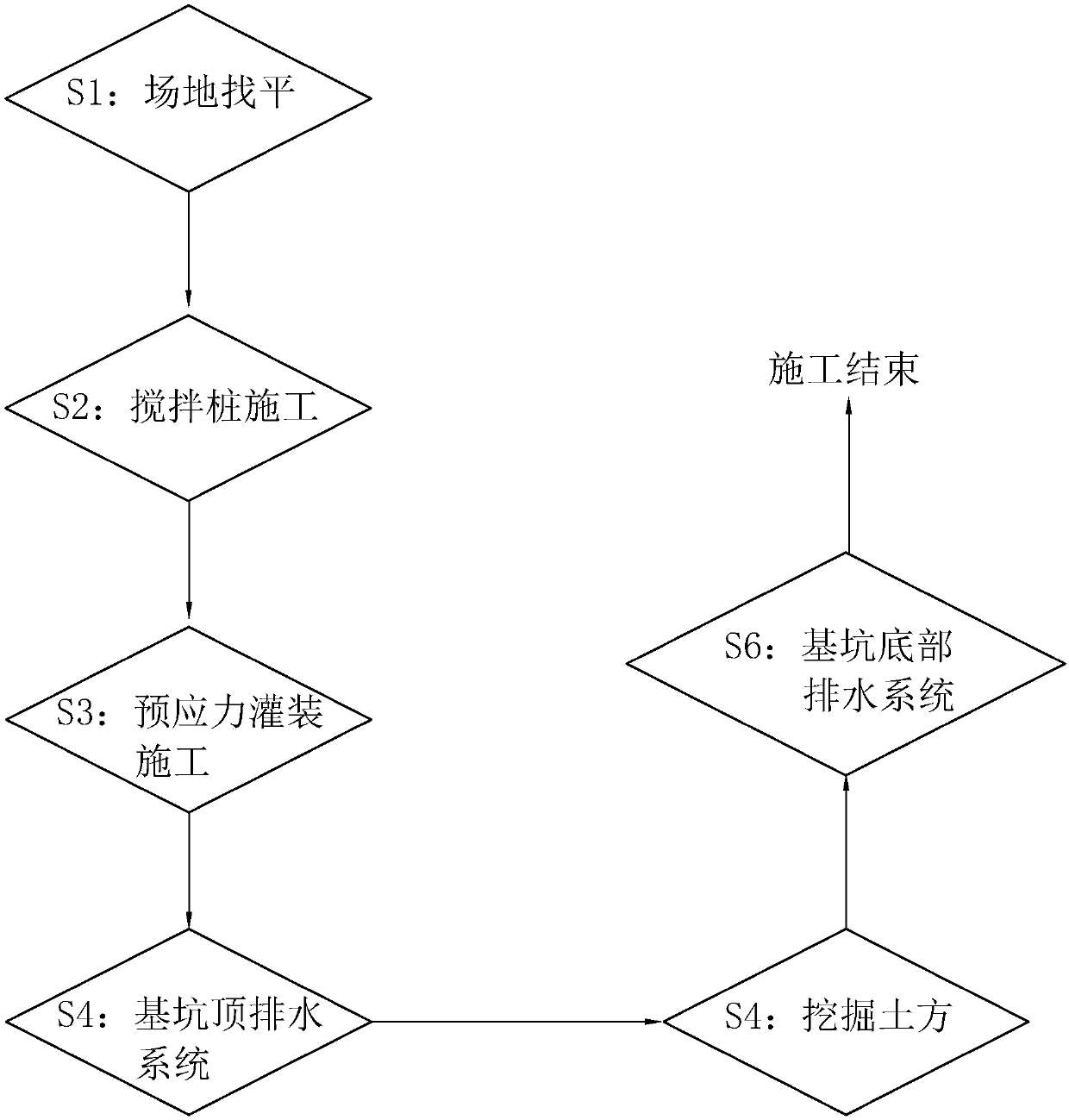

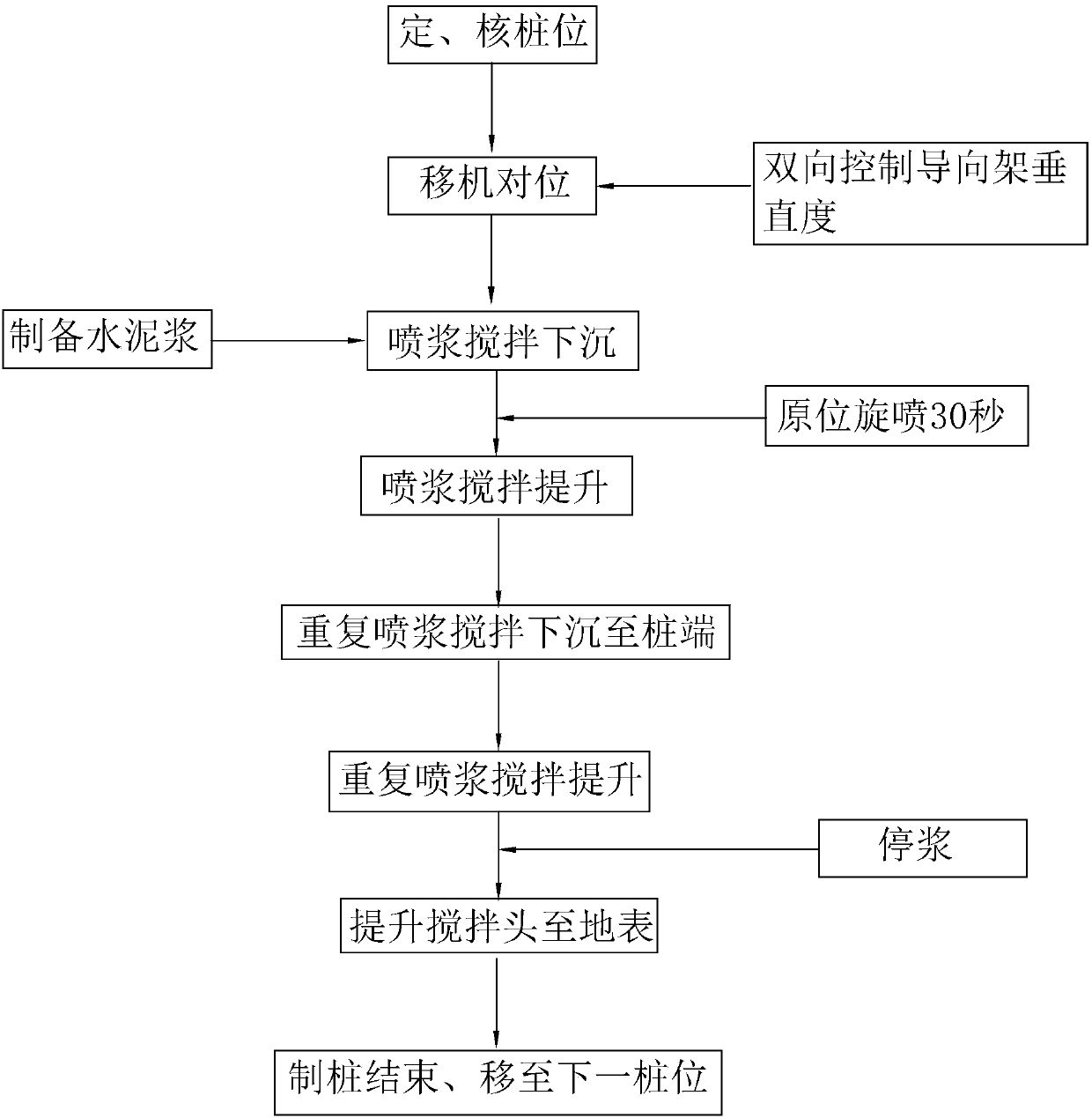

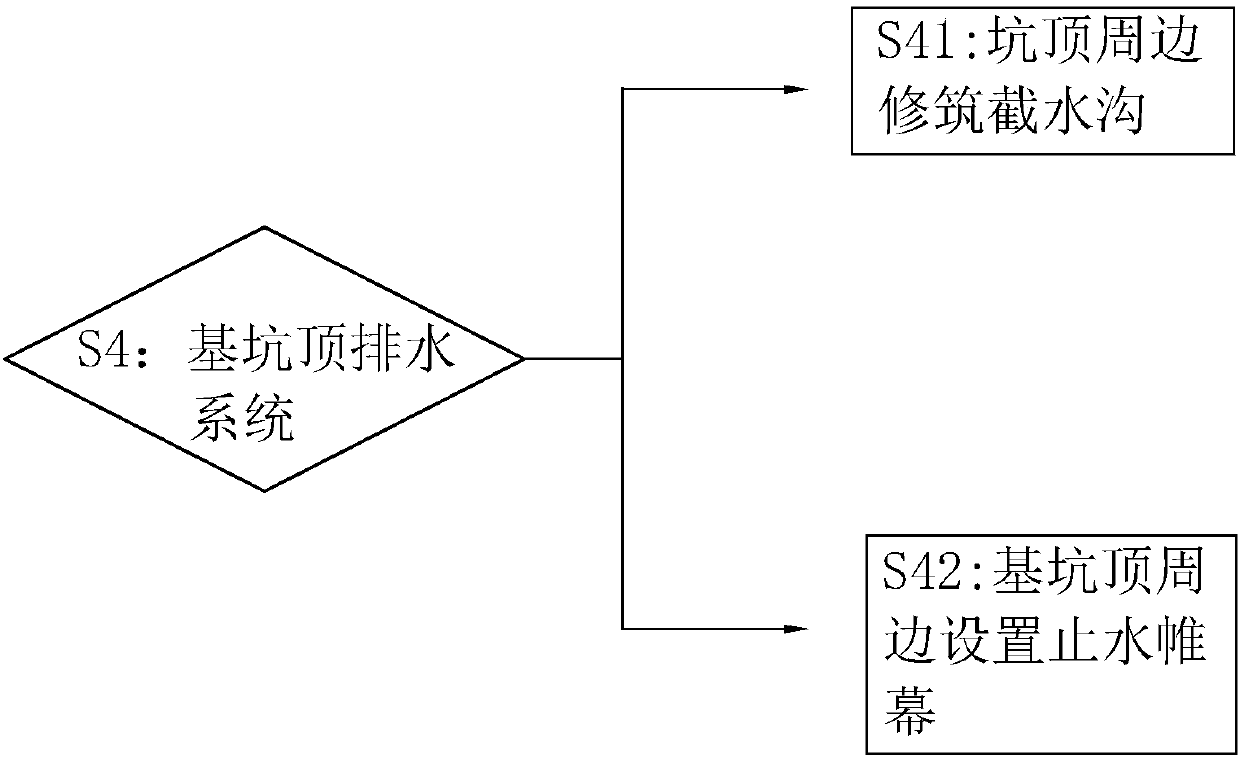

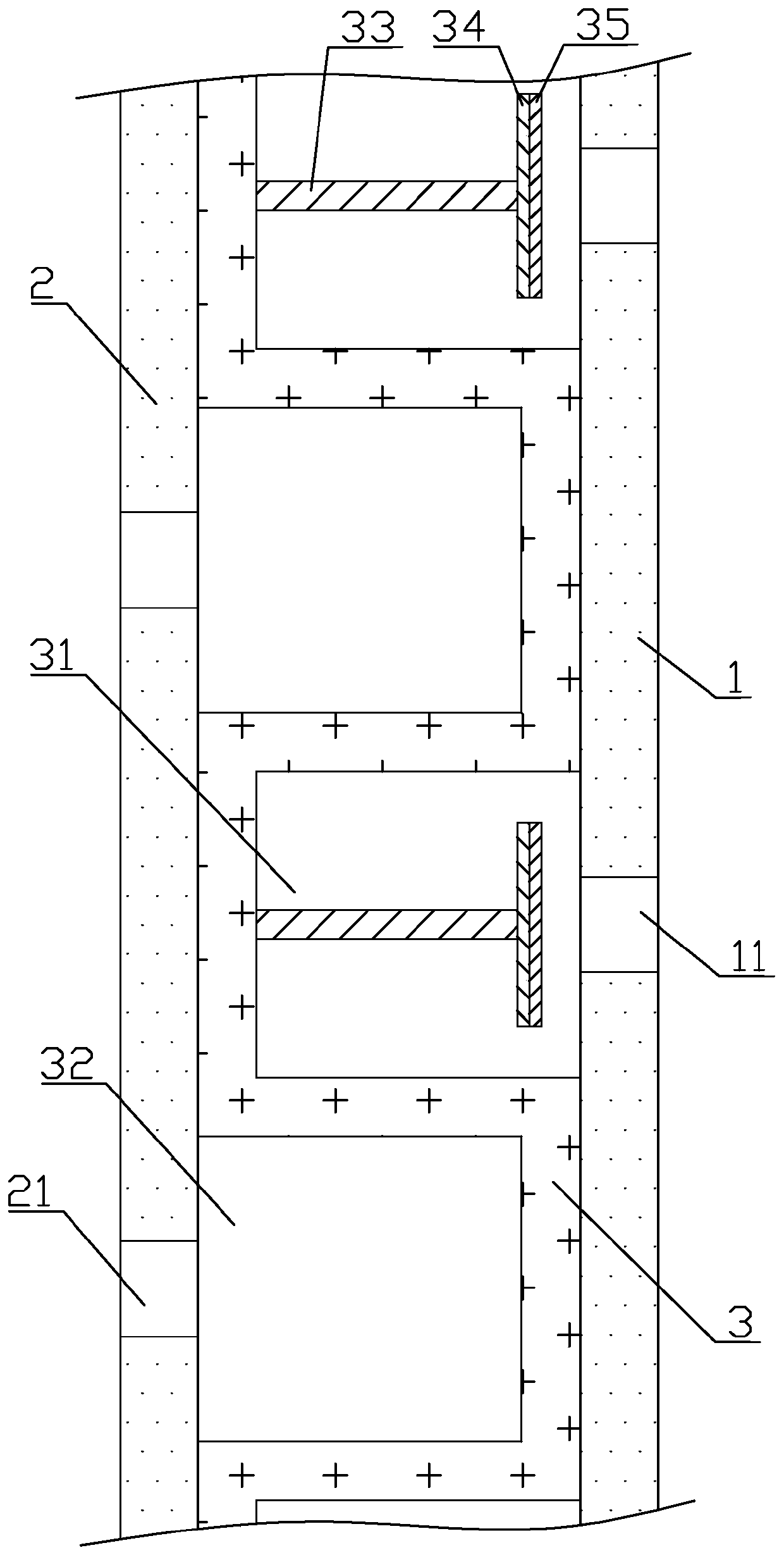

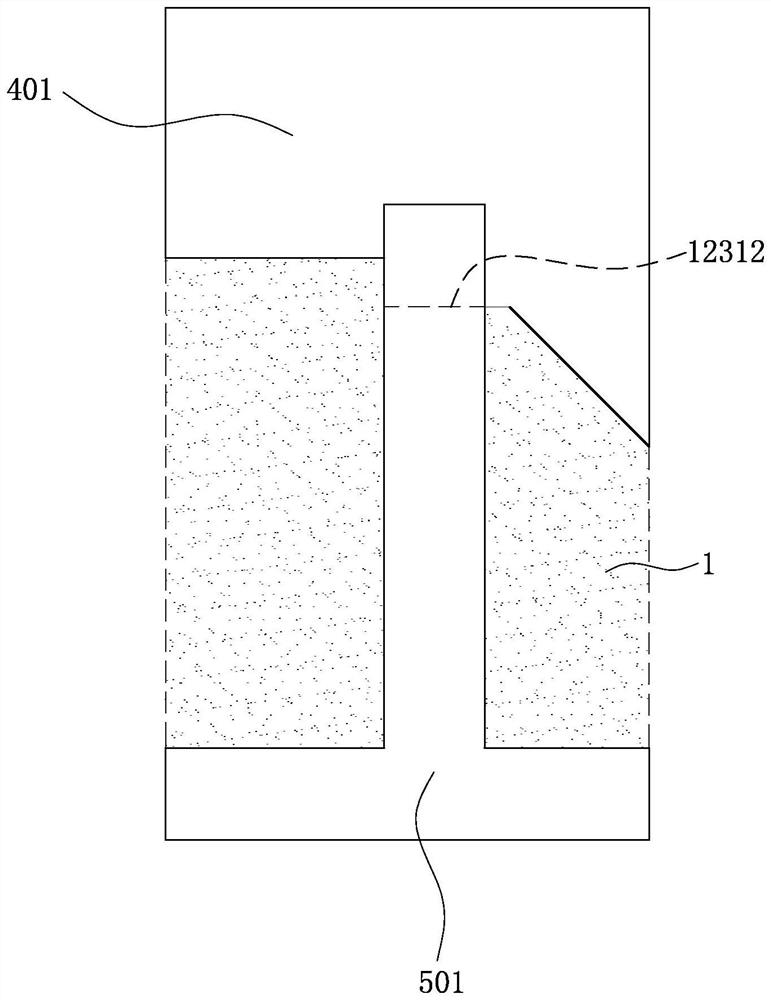

Construction method of foundation pit supporting and earth excavation of building basement

The invention relates to a construction method of foundation pit supporting and earth excavation of a building basement. The construction method comprises the following steps that S1, a site is leveled, side setting-out of an edge line is conducted, the axis is constructed, and the pile position of a stirring pile is determined; S2, the stirring pile is constructed; S3, a prestressed pipe pile isconstructed; S4, a foundation pit top drainage system is constructed; S5, earth is excavated; and S6, a foundation pit bottom drainage system is arranged. A building is arranged under underground water, and therefore water stopping or drainage devices such as a water stopping curtain and a water collection well are arranged on the peripheral side of a foundation pit. As for blocking of surface water, the main steps are that a water blocking concrete foundation is arranged on the top of a side slope; the top of the slope is slightly high, so that the surface water is drained into a drainage ditch outside the foundation pit; and meanwhile the ground on the top of the slope is subjected to hardening treatment, so that the surface water and rainwater are prevented from permeating into a protecting wall of the side slope. The drainage ditch and the water collection well are arranged in the foundation pit along the periphery of the foundation pit according to the design requirement, water inthe foundation pit is drained timely, and the situation that the surface water or the underground water affects the structural strength of the foundation pit is avoided.

Owner:广州市番禺区第五建筑工程公司

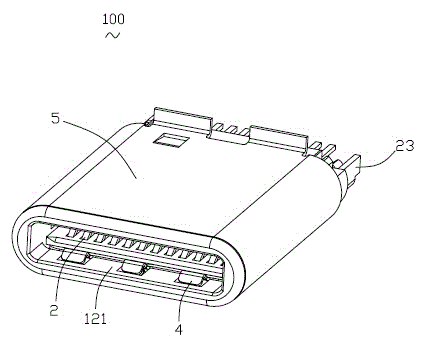

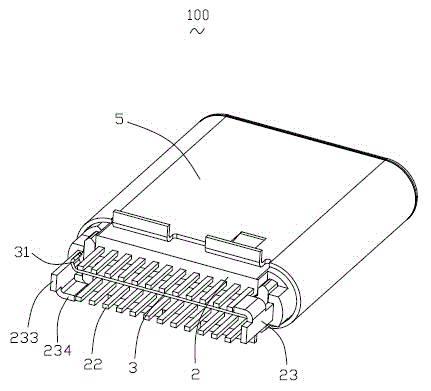

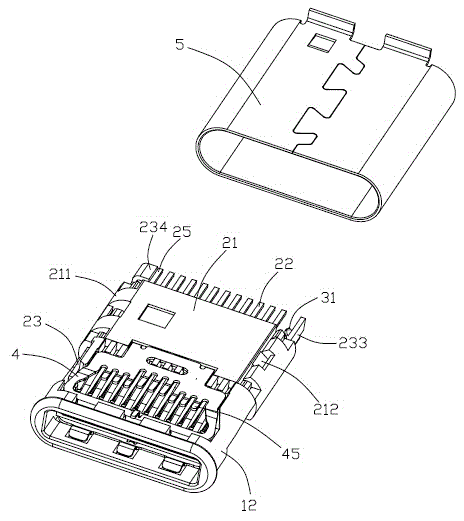

Electric connector and manufacturing method thereof

InactiveCN105470690AAffects structural strengthEasy to manufactureContact member assembly/disassemblySecuring/insulating coupling contact membersElectricityButt joint

The invention provides an electric connector and a manufacturing method thereof. The electric connector comprises an insulating body, a central grounding piece and terminal assemblies. The insulating body is provided with a butt joint part, a main body part, an upper accommodating cavity and a lower accommodating cavity, wherein the upper accommodating cavity is formed on the upper side of the main body part, and the lower accommodating cavity is formed on the lower side of the main body part. The butt joint part comprises an accommodating space which is open forward, a top wall, a bottom wall and two side walls. The central grounding piece is fixed in the main body part. Each terminal assembly is provided with an insulating block arranged in the upper accommodating cavity or the lower accommodating cavity, electric conduction terminals fixed in the insulating block and a latch spring piece, wherein the latch spring piece is arranged outside the electric conduction terminals; the latch spring piece is provided with a fixed part fixed in the insulating block, a latch arm which extends from the front side of the fixed part into the accommodating space in a protruding manner, and an extending arm which is formed through extension from the rear side of the fixed part; and each electric conduction terminal is provided with a contact arm which protrudes forward into the accommodating space.

Owner:ALLTOP ELECTRONICS SU ZHOU +1

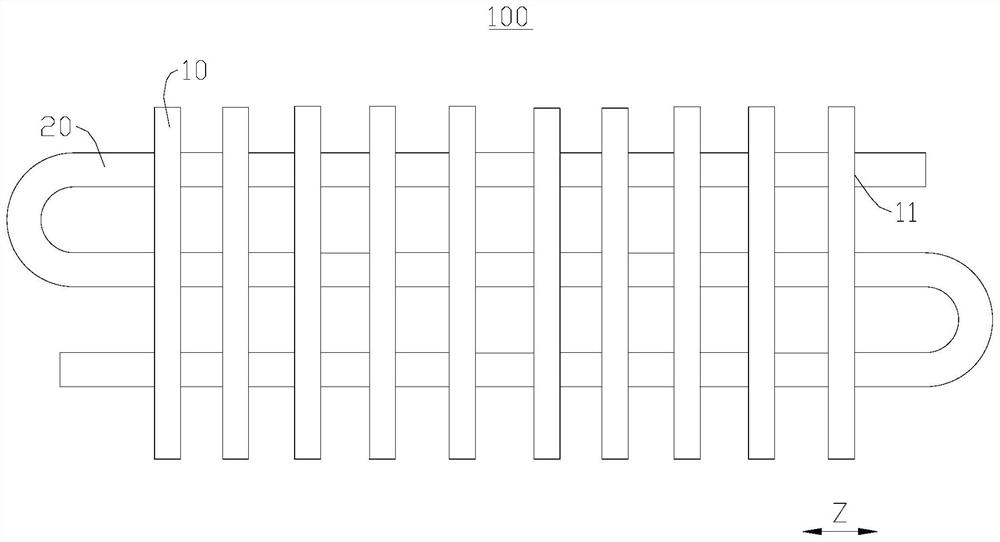

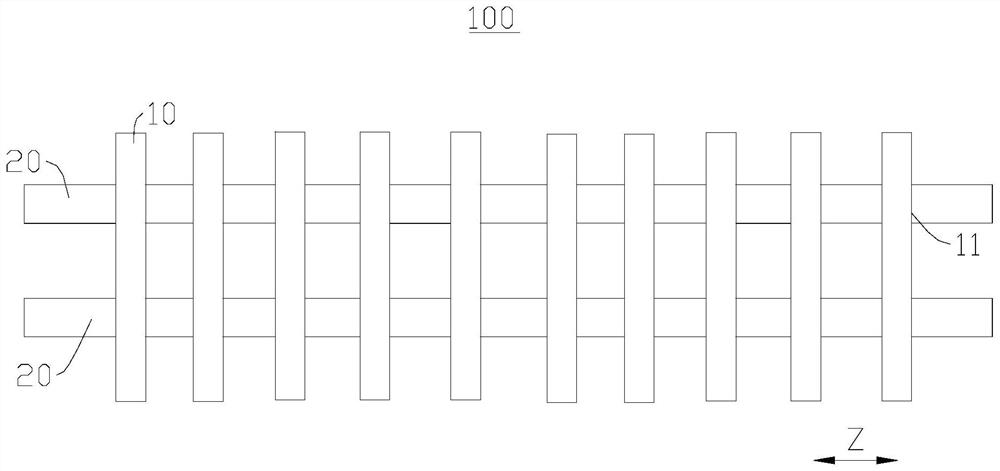

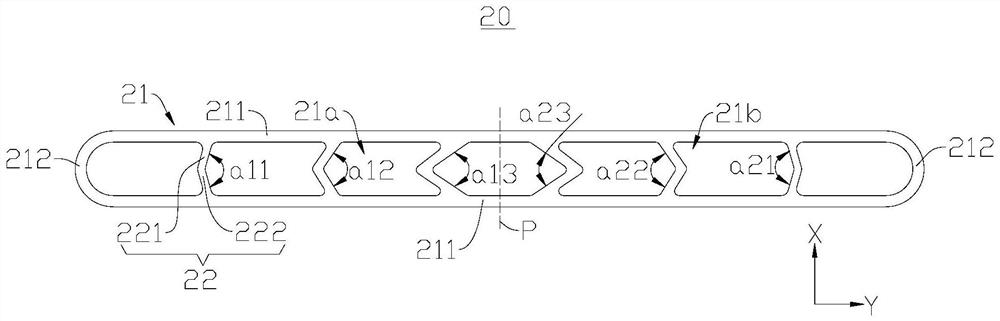

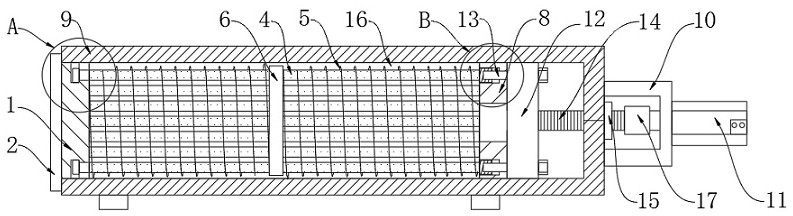

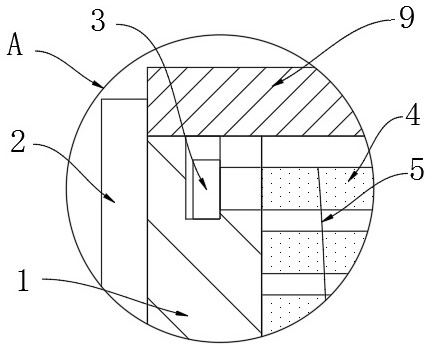

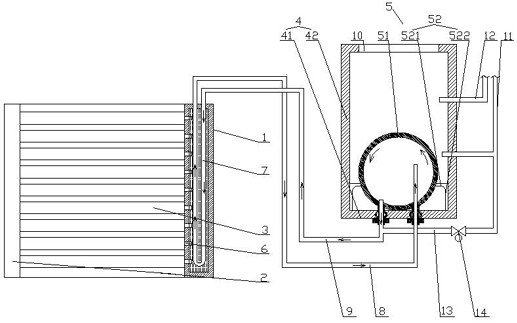

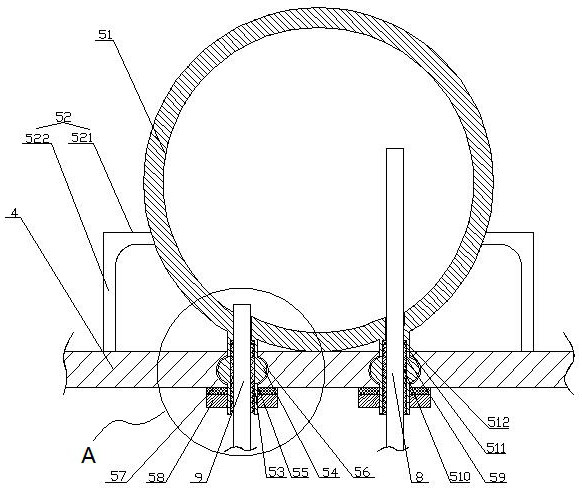

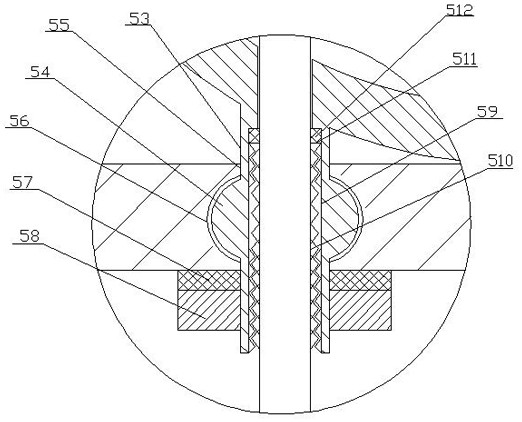

Heat exchanger and manufacturing method thereof

PendingCN114440687ALimit maximum deformationImprove structural strengthHeat exchanger casingsIce removalAir volumeEngineering

The invention provides a heat exchanger and a manufacturing method thereof, and relates to the technical field of heat exchange. The heat exchanger comprises fins and flat pipes; the fins are provided with mounting holes; each flat pipe comprises a pipe body and a reinforcing part, the pipe bodies are inserted into the mounting holes and connected with the fins in an expanded mode, the reinforcing parts are arranged in the pipe bodies and connected with the inner surfaces of the pipe bodies, and the reinforcing parts are configured to allow the pipe bodies to deform and limit the maximum deformation amount of the pipe bodies. The tube body of the flat tube is in expanded connection with the fins to fix the flat tube to the fins, so that the flat tube and the fins are fixedly connected without welding, the hydrophilicity of the hydrophilic layer of the fins is not affected, and the air volume of the heat exchanger and the heat exchange efficiency of the heat exchanger are prevented from being reduced. The reinforcing part in the pipe body can limit the maximum deformation amount of the pipe body, and the situation that the structural strength of the pipe body is affected due to excessive deformation of the pipe body in the pipe expanding process is avoided. And the reinforcing part can also play a role in reinforcing the structural strength of the tube body so as to prolong the service life of the flat tube and the heat exchanger.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

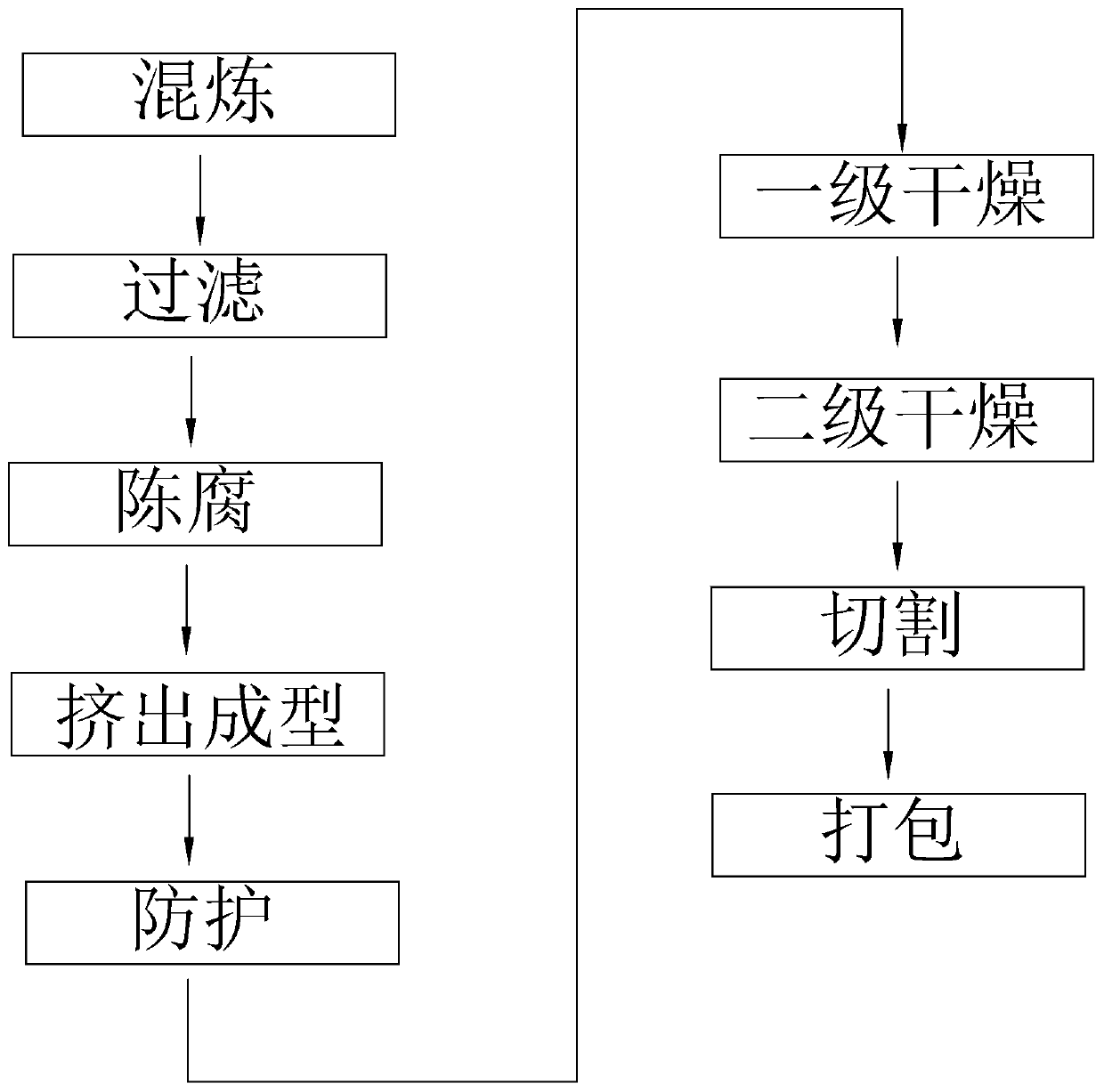

Denitration catalyst production process

PendingCN110743533AAffects structural strengthAvoid crackingDispersed particle separationCatalyst activation/preparationPtru catalystHoneycomb like

The invention discloses a denitration catalyst production process, which comprises: A1, mixing; A2, filtering; A3, ageing; S4, extrusion molding: putting the aged raw material into an extruder, and extruding the raw material from an extruder mold to form a honeycomb-like catalyst crude product; A5, protection: packaging and sealing the catalyst crude product by using a protection paper shell; A6,primary drying: placing the protected catalyst crude product on a cart, pushing into a drying chamber, and drying; A7, secondary drying; A8, roasting; A9, cutting; and A10, packaging, wherein the stepA6 is divided into four stages, the first stage is a heating constant-humidity stage, the second stage is a constant-temperature constant-humidity stage, the third stage is a constant-temperature dehumidification stage, and the fourth stage is a gentle cooling stage. According to the invention, with the production process, cracks are prevented from being generated on the surface of the catalyst product, and the structural strength of the catalyst product is guaranteed.

Owner:SHANDONG BOLIN ENVIRONMENTAL PROTECTION TECH DEV

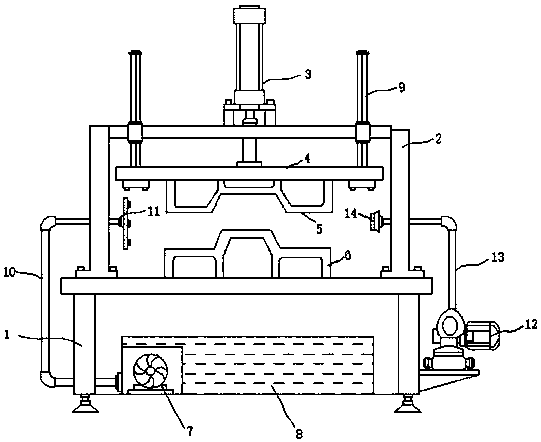

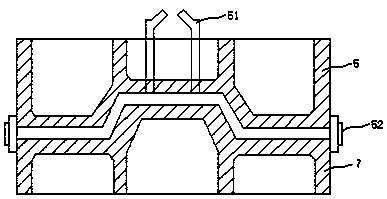

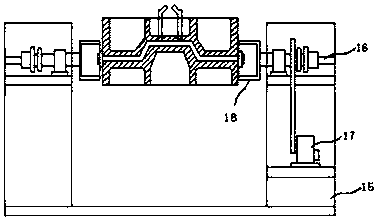

Die for producing autobody and die turnover mechanism

InactiveCN108555242AEasy to operateImprove securityFoundry mouldsFoundry coresSpray nozzleWater pipe

The invention discloses a die for producing an autobody and a die turnover mechanism. The die comprises an apparatus fixing rack, a supporting shelf is fixedly installed in an inner cavity of the apparatus fixing rack through bolts, and a driving air cylinder is arranged at the top of the supporting shelf; the power output end of the bottom of the driving air cylinder is connected with a lifting plate located in an inner cavity of the supporting shelf; a water pump is further arranged in a water tank, the output end of the water pump is connected with one end of a water pipe, and the other endof the water pipe is connected with a nozzle; an air compressor is further arranged on the right side wall of the apparatus fixing rack, the output end of the air compressor is connected with one endof an air delivery pipe, and an upper die base and a lower die base constitute a die structure. The die has the advantages that the upper die base is fixed to the lifting plate, the driving air cylinder is utilized to drive the lifting plate to move downwards and coincide with the lower die base to form the die structure, and an injection pipe is utilized o inject an alloy solution into the die;the die is easy and convenient to operate, die compounding and die opening do not need to be conducted manually, and the safety of operators is improved.

Owner:王甲亮

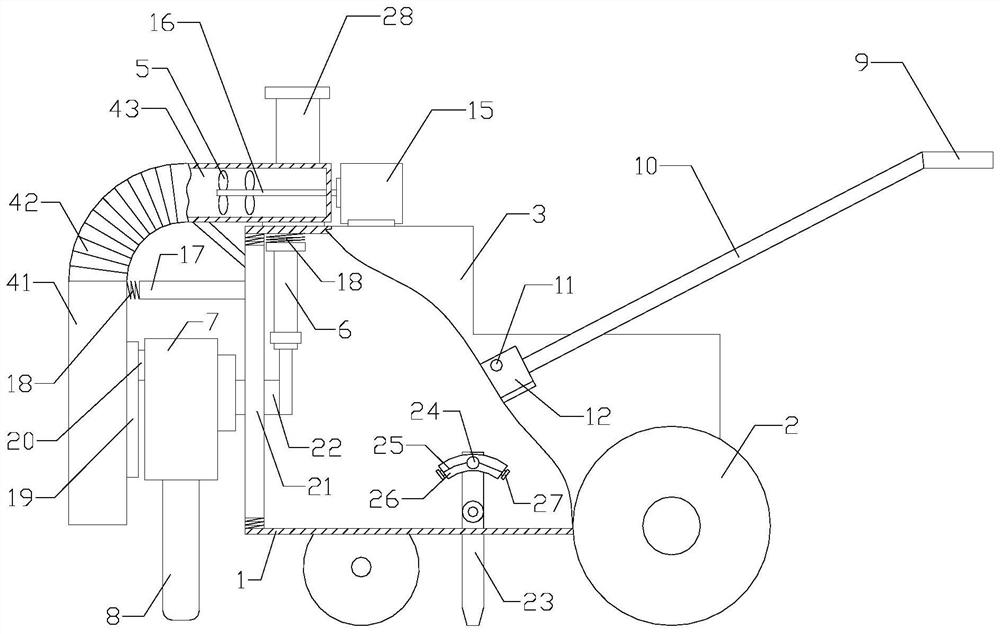

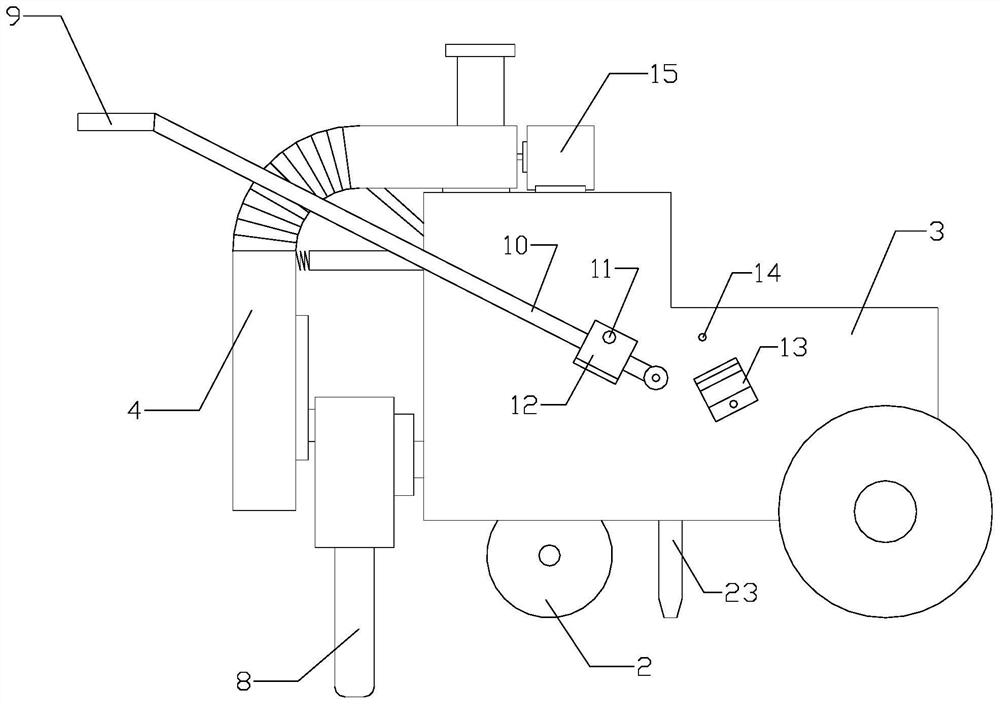

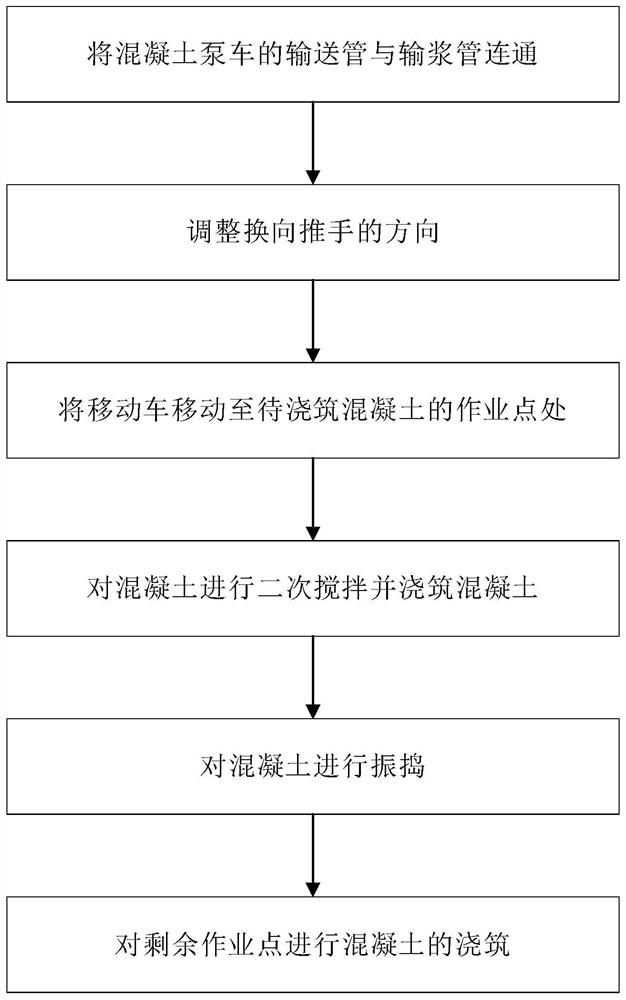

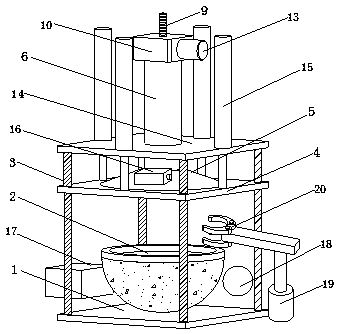

Concrete pouring device for water conservancy project building and using method of concrete pouring device

ActiveCN112359835AEase of pouringUniform textureFoundation engineeringMobile vehicleArchitectural engineering

The invention discloses a concrete pouring device for a water conservancy project building and a using method of the concrete pouring device. A cabinet body is arranged on a mobile vehicle of the device, and a reversing pushing hand is arranged on one side of the cabinet body; a concrete secondary stirring mechanism comprises a slurry conveying pipe used for conveying concrete and a stirring unit,and stirring blades of the stirring unit are located between a slurry outlet and a slurry inlet of the slurry conveying pipe; a concrete vibrating mechanism comprises a lifting unit, a vibrating motor and a vibrating rod, the vibrating motor and the vibrating rod are arranged on the mounting seat, and an output shaft of the vibrating motor is connected with a rotating shaft in the vibrating rod;and the telescopic end of the lifting unit is connected with the mounting base. The method comprises the steps of making a conveying pipe of a concrete pump truck and the slurry conveying pipe communicate; moving the mobile vehicle to an operation point of the concrete to be poured; carrying out secondary stirring on the concrete and pouring the concrete; and carrying out vibration of concrete According to the concrete pouring device, concrete conveyed into an reinforcement cage can be uniform in texture, bubbles in the concrete can be removed in time, and the quality of a concrete structure is guaranteed.

Owner:杨玉庆

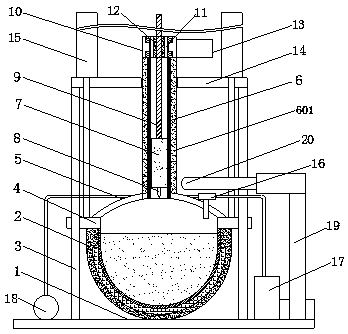

Single crystal silicon refining production process and refining device thereof

InactiveCN110528074AControl spawn rateAffects structural strengthPolycrystalline material growthBy pulling from meltBall screwGraphite

The invention belongs to the technical field of single crystal silicon refining, and particularly relates to a single crystal silicon refining production process and a refining device thereof. The refining device comprises a base; a furnace body is fixedly installed at the middle of the top of the base, and four guide pillars are fixed to the sides of the base. A lifting plate is movably fitted inthe middle portions of the four guide columns. A furnace cover is fixedly fastened to the middle of the lifting plate. The top of the furnace cover is vertically connected with a stretching tube. Theinner wall of the stretching tube is fitted with a graphite piston. The bottom end is vertically connected with a seed rod, and the top end of the graphite piston is vertically fixedly connected witha ball screw. In the invention, the servo motor is driven to rotate the screw nut through the gearbox, and then the ball screw and the graphite piston are screwed down to move along the stretching tune, so that the seed rod can contact the silicon melt, and the rotation speed can be accurately controlled. The necking growth process, the shoulder growth process, the isometric growth process and the tail growth process can be well ensured, and the formation speed of the single crystal silicon rod can be precisely controlled.

Owner:南通晶耀新能源有限公司

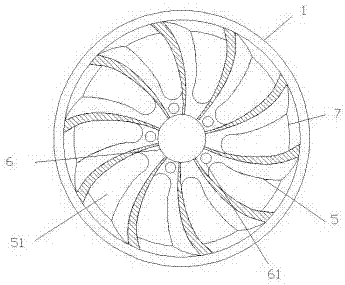

Novel hub for sedan car

InactiveCN107323166AAffects structural strengthImprove safety and reliabilityRimsDisc wheelsThrust bearingEngineering

The invention discloses a new wheel hub for cars, which includes a hub body, the hub body includes an outer hub and an inner hub, the outer hub and the inner hub are fixedly connected by buckles, and the buckles are evenly distributed on the connection of the rim On the surface, the buckle includes a fixed clip and a connecting clip, the connecting clip is connected with the fixed clip, the surface of the outer hub is provided with spokes, and the spokes are evenly distributed inside the rim, and the outer A fixing seat is arranged at the center of the hub, and a plurality of fixing holes are evenly arranged on the surface of the fixing seat, through holes are arranged between the spokes, and inclined wheel grooves are arranged on the edge of the through holes near the rim. By setting fan blade-type spokes on the surface of the outer hub, during the rotation of the hub, the air inside the hub is drawn out to the outside, which improves the heat dissipation efficiency of the bearing inside the hub and improves the service life of the bearing; by using the buckle connection type The wheel hub reduces the difficulty of operation when installing tires.

Owner:MAANSHAN ZHICHENG SCI & TECH

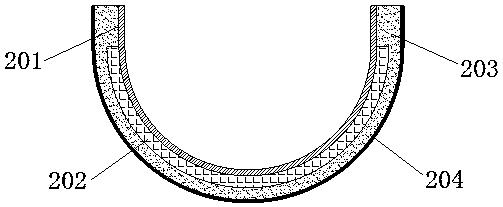

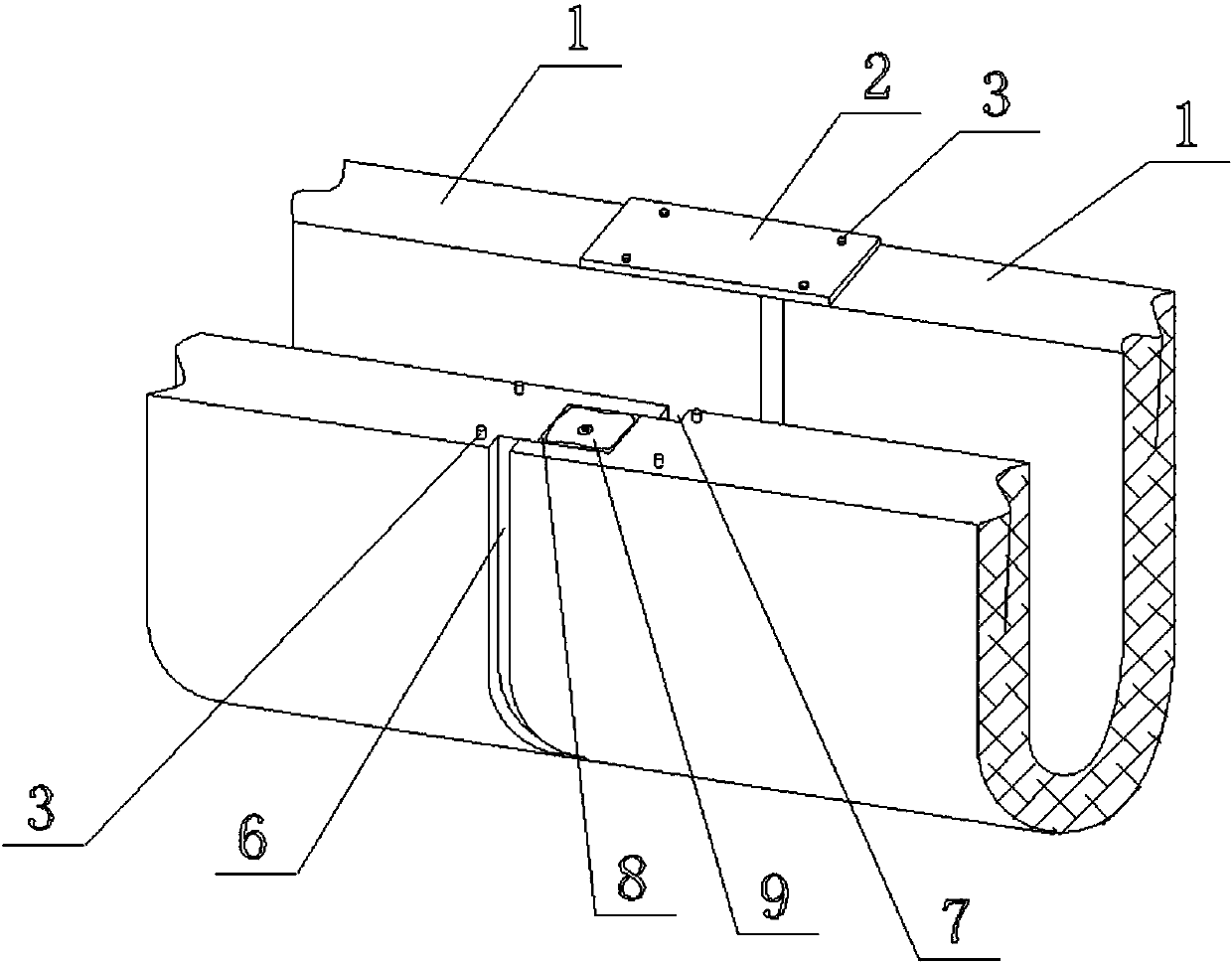

Quickly mounted prefabricated drainage ditch

The invention discloses a quickly mounted prefabricated drainage ditch. Three layers of steps are arranged at one end of a U-shaped drainage ditch concrete unit block to form an outer step region while three layers of steps are arranged at the other end to form an inner step region, two adjacent unit blocks are in butt joint to form a butt joint reserving cavity, and an inflating bag is assembledin the butt joint reserving cavity in a matched manner. The quickly mounted prefabricated drainage ditch disclosed by the invention can be quickly assembled and detached and repeatedly used. By arranging the inflating bag, the demand on the sealing precision of the butt joint surface of two adjacent unit bodies is not high, so that the unit bodies can be fully sealed. The quickly mounted prefabricated drainage ditch is reasonable in structural design, good in using effect and convenient to mount and detach, and can be repeatedly used. The unit pieces are standardized, so that the quickly mounted prefabricated drainage ditch is suitable for batch manufacturing and processing, can be purchased or leased to use and is suitable for being popularized and applied.

Owner:郑州宇恒环保技术有限公司

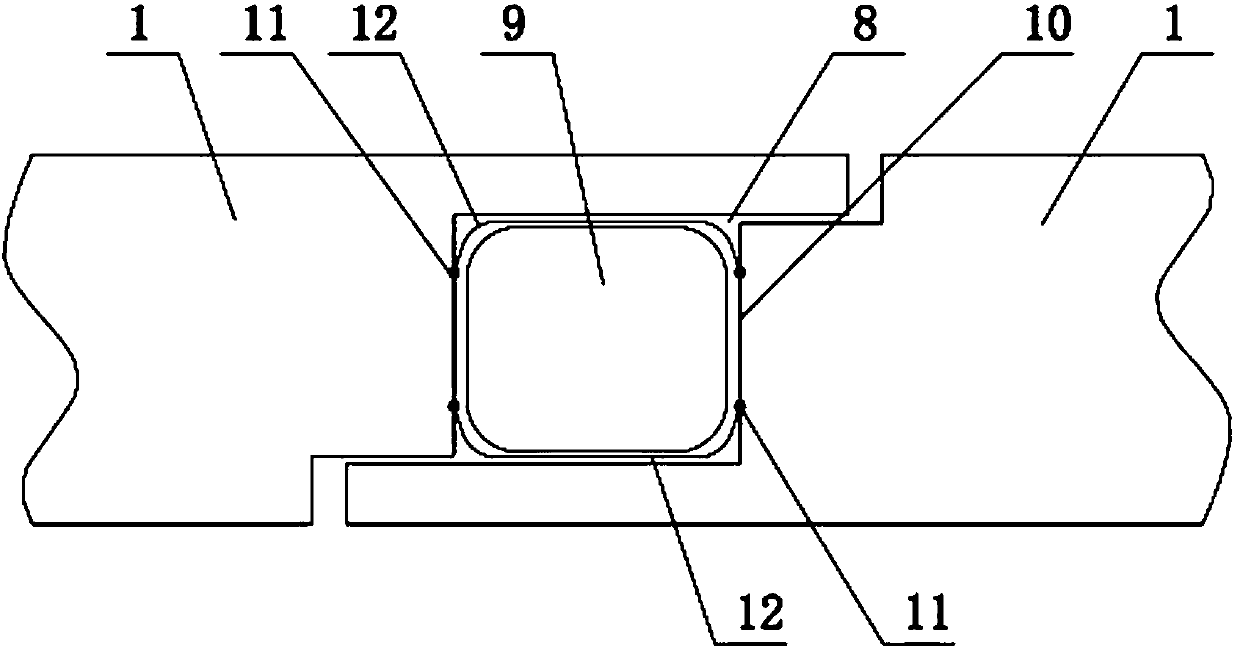

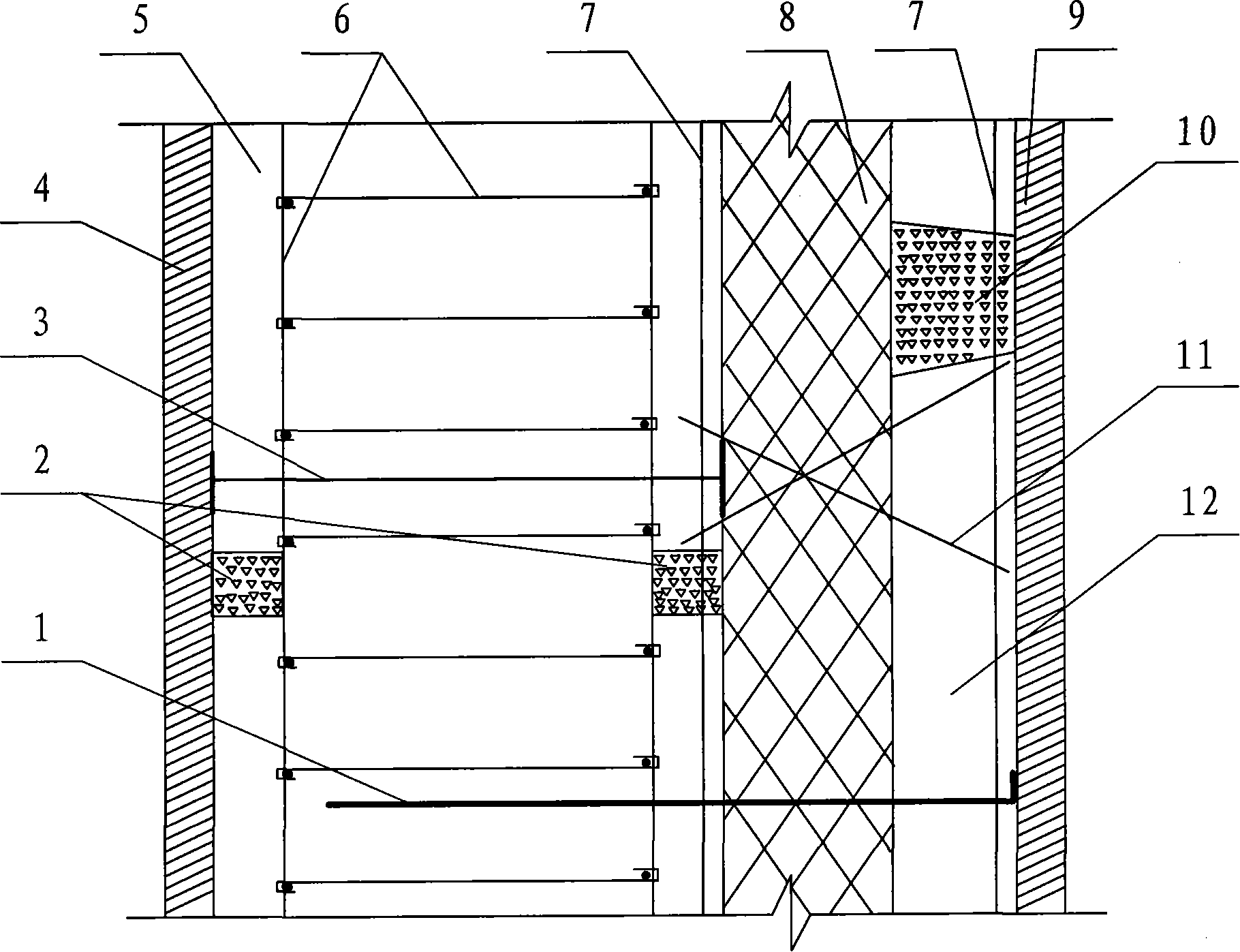

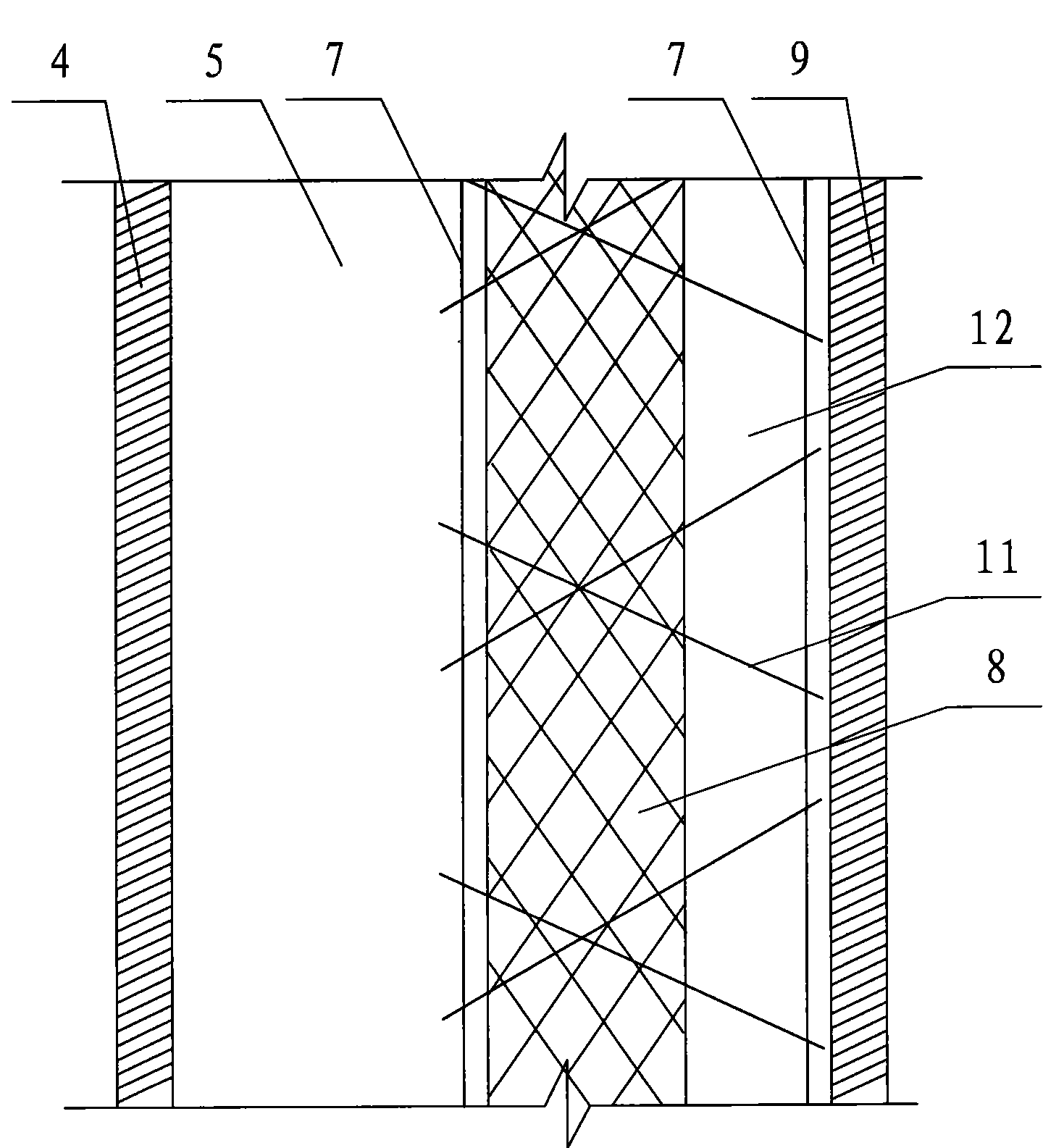

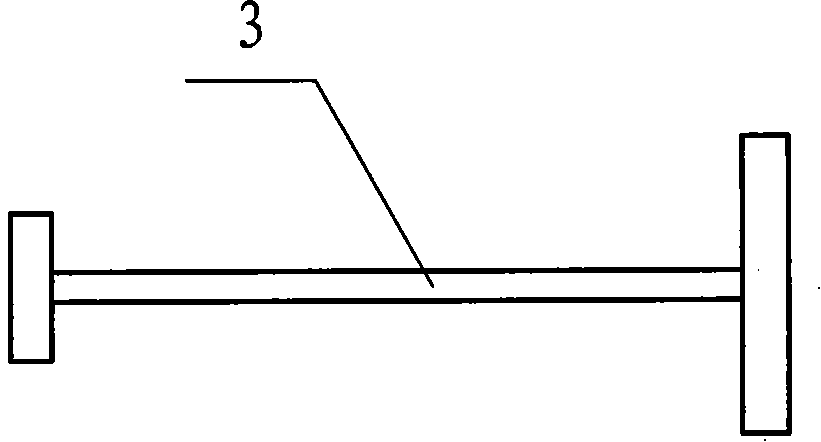

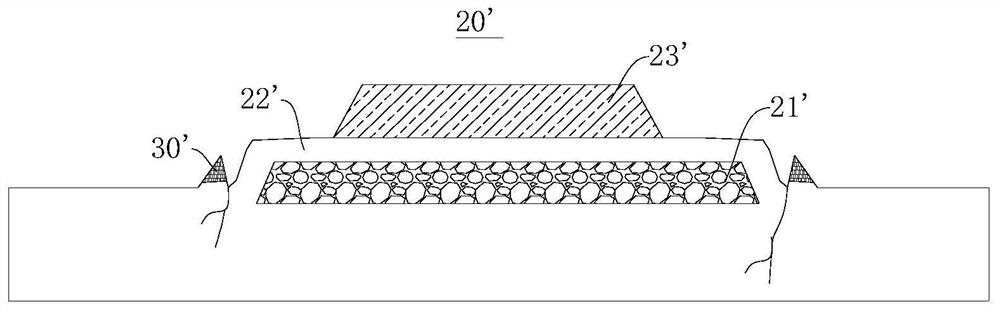

Construction method for embedding thermal insulation in concrete structure exterior wall surface

InactiveCN101294423BIntrinsic Quality GuaranteeGuaranteed appearanceWallsHeat proofingInsulation layerThermal insulation

The invention discloses a construction method of a concrete structure external wall with a built-in thermal insulating layer. The construction method comprises the steps of putting polystyrene plates among multiple layers of reinforcing meshes, obliquely inserting reinforcing steel bars in three-dimensional direction, welding the steel bars to obtain a thermal insulating wire rack board, and simultaneously pouring concrete on both internal and external sides to form a structural system. The specific construction method comprises the steps of: fabricating the thermal insulating wire rack board, banding external wall boundary members (embedded columns) and external wall board steel bars, installing the thermal insulating wire rack board, connecting steel bars around the thermal insulating wire rack board and laying pipelines, installing and fixing steel struts on the inner side of the thermal insulating wire rack board and cushion blocks on the outer side of the thermal insulating wire rack board, erecting inner templates for an external wall, erecting outer templates for the external wall, testing, simultaneously pouring concrete at both the internal side and the external side, removing templates, and curing. The inventive concrete structure external wall with the built-in thermal insulating layer has the advantages of solid connection, good sound insulating and thermal insulating effects, long service life, simple construction method, good shock resistant effect, short construction time, environmental friendliness, low construction cost, and good social and economic benefits; and is suitable for various urban residential buildings.

Owner:HENAN NO 1 CONSTR ENG GRP

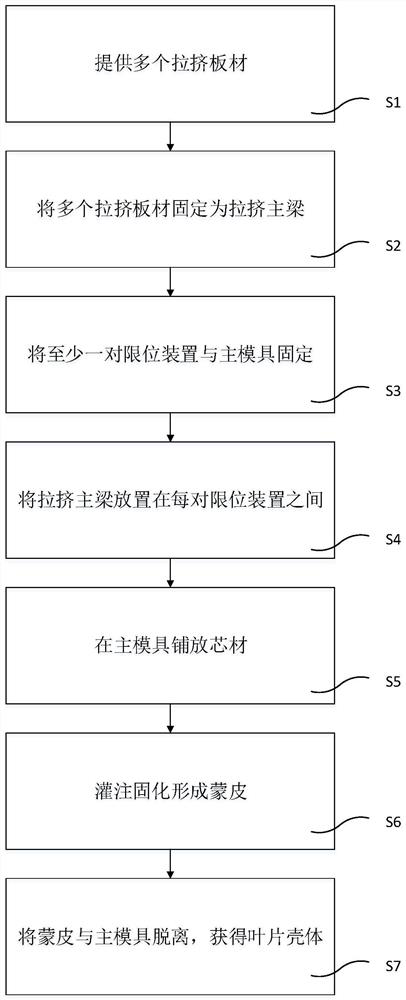

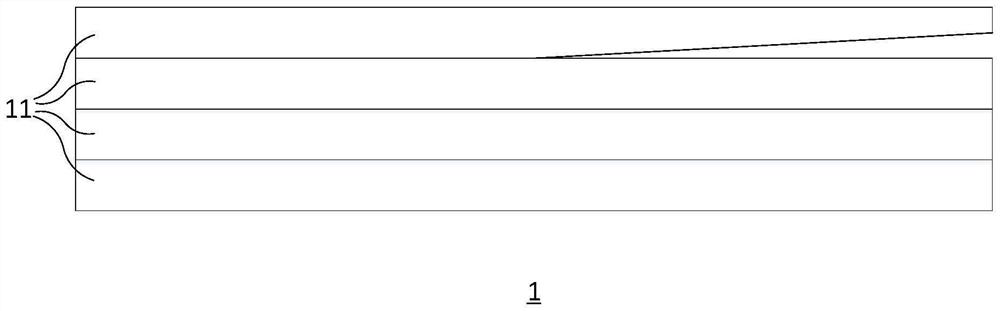

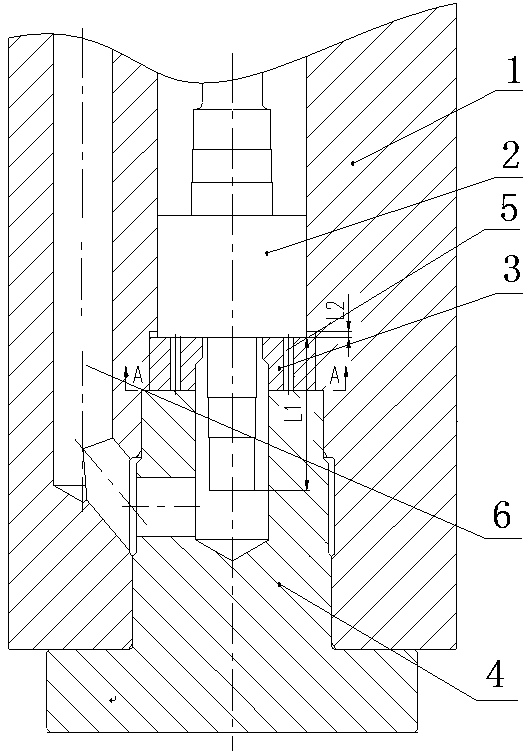

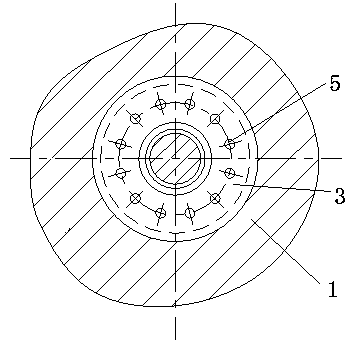

Blade shell preparation method and blade

InactiveCN113119495AAffects structural strengthHigh strengthFinal product manufactureWind energy generationForeign matterStructural engineering

The invention discloses a blade shell preparation method and a blade. The blade shell preparation method comprises the following steps that a plurality of pultrusion strips are provided; the plurality of pultrusion strips are stacked to form a main beam; at least one pair of limiting devices are fixed to a blade mold; the main beam is placed between each pair of limiting devices; a core material is laid on the blade mold; pouring and curing are performed to form a shell; and the shell is separated from the blade mold, and the blade shell is obtained. The limiting devices are arranged in the blade mold, and after the main beam is placed in the blade mold and when a fixing device is detached, the pultrusion strips are prevented from displacement or deformation through the limiting devices, so that the main beam can be kept in an expected shape, and the situation that foreign matters such as a binding rope and the like are introduced to affect the structural strength of the blade is avoided.

Owner:SINOMATECH WIND POWER BLADE

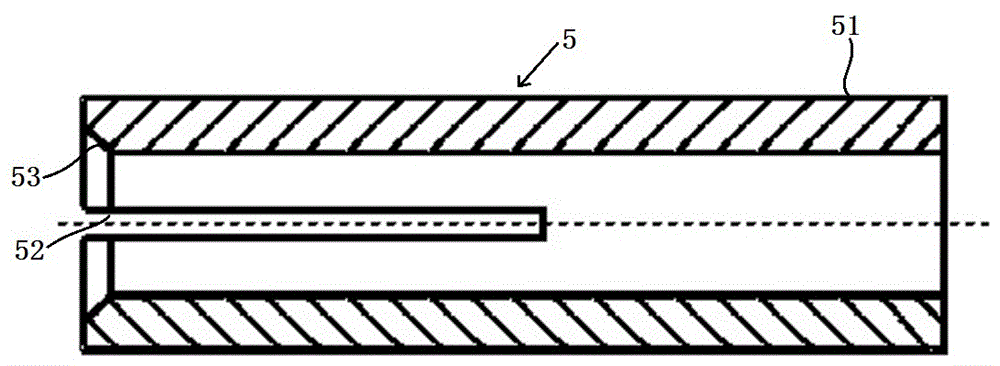

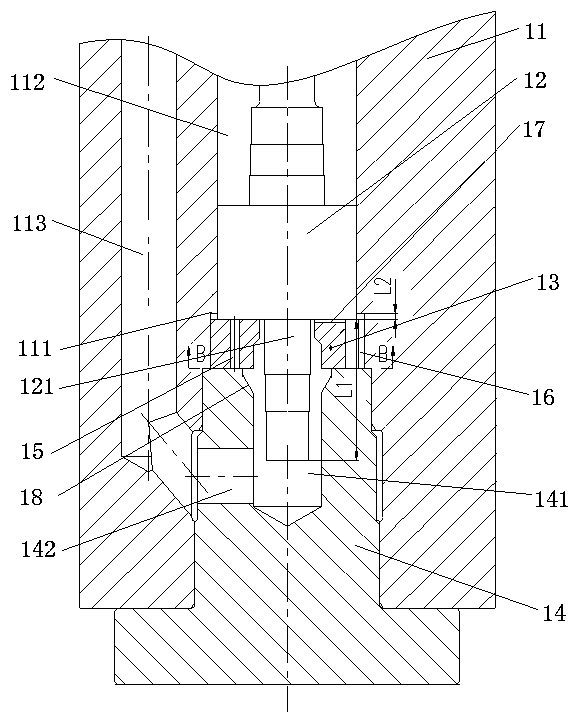

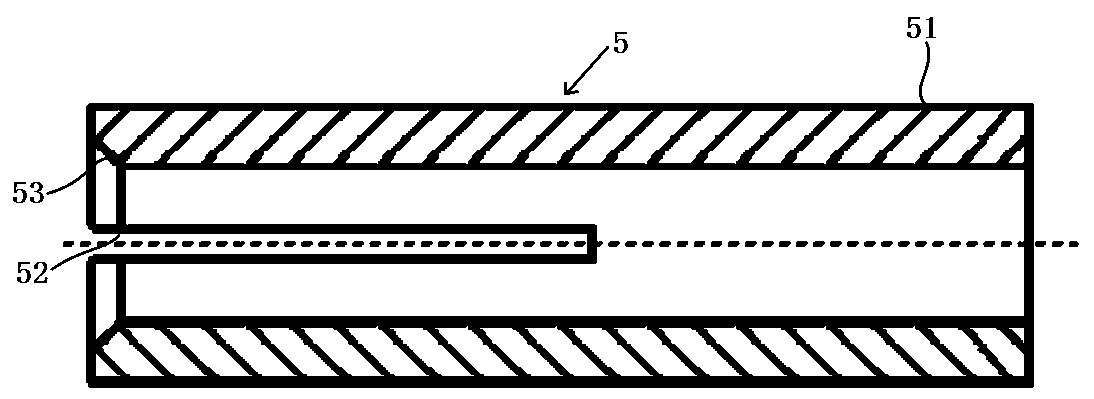

Buffer sleeve and working cylinder of hydraulic device using buffer sleeve

ActiveCN110159615AIncrease motivationIncrease the area of actionFluid-pressure actuatorsEngineeringMechanical engineering

The invention relates to a buffer sleeve and a working cylinder of a hydraulic device using the buffer sleeve. The buffer sleeve is arranged between a stopping step and a plugging head of the workingcylinder of the hydraulic device, and an inner hole allowing a buffer shaft of a piston to be inserted is formed in the buffer sleeve. Oil passing grooves are formed in the end surface of the end, faraway from the plugging head, of the buffer sleeve, and the oil passing grooves communicate with the inner hole of the buffer sleeve. According to the buffer sleeve and the working cylinder of the hydraulic device using the buffer sleeve, due to the fact that the buffer sleeve is arranged between the stopping step and the plugging head of the working cylinder of the hydraulic device, when the working cylinder of the hydraulic device is started, oil can enter the oil passing grooves through gaps between the piston and the inner hole of the buffer sleeve, and the oil entering the oil passing grooves has a driving effect on the piston. Compared with the prior art, the action area of initial oil on the piston is expanded, so that the moving speed of the piston can be increased, thus improvingthe starting force of the working cylinder of the hydraulic device so as to achieve the effect of improving the starting speed of the working cylinder of the hydraulic device.

Owner:PINGGAO GRP +1

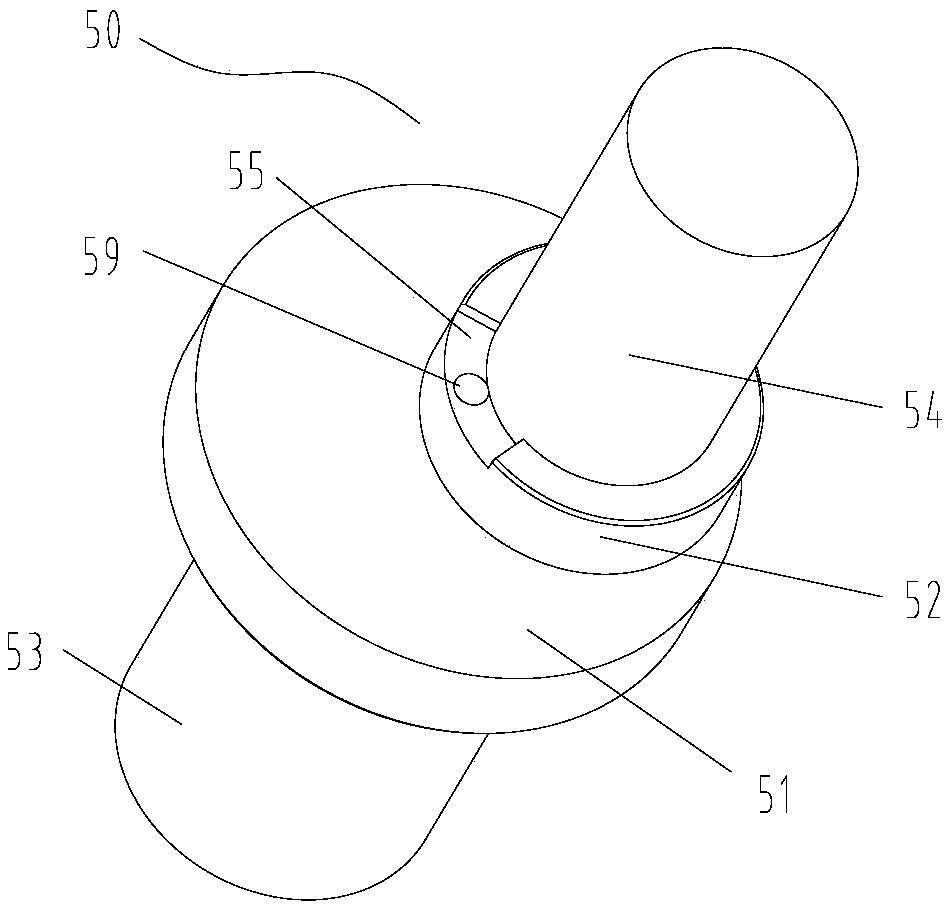

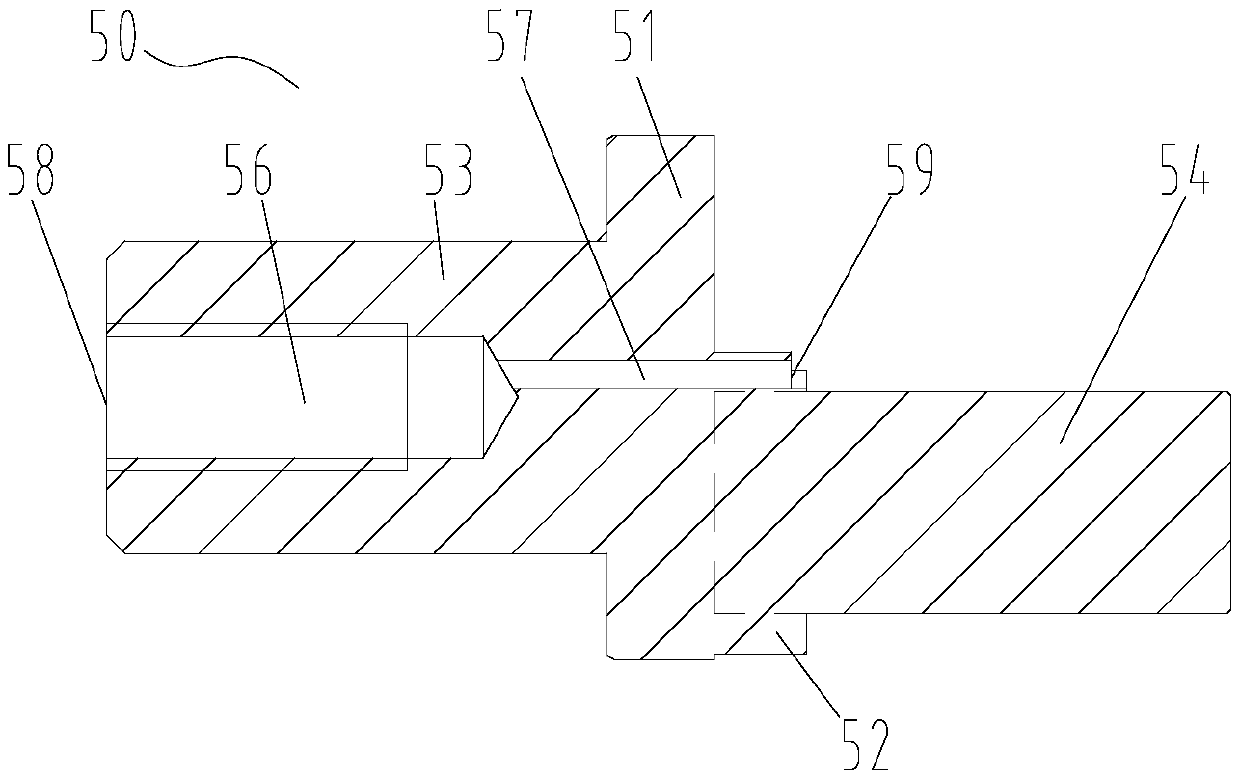

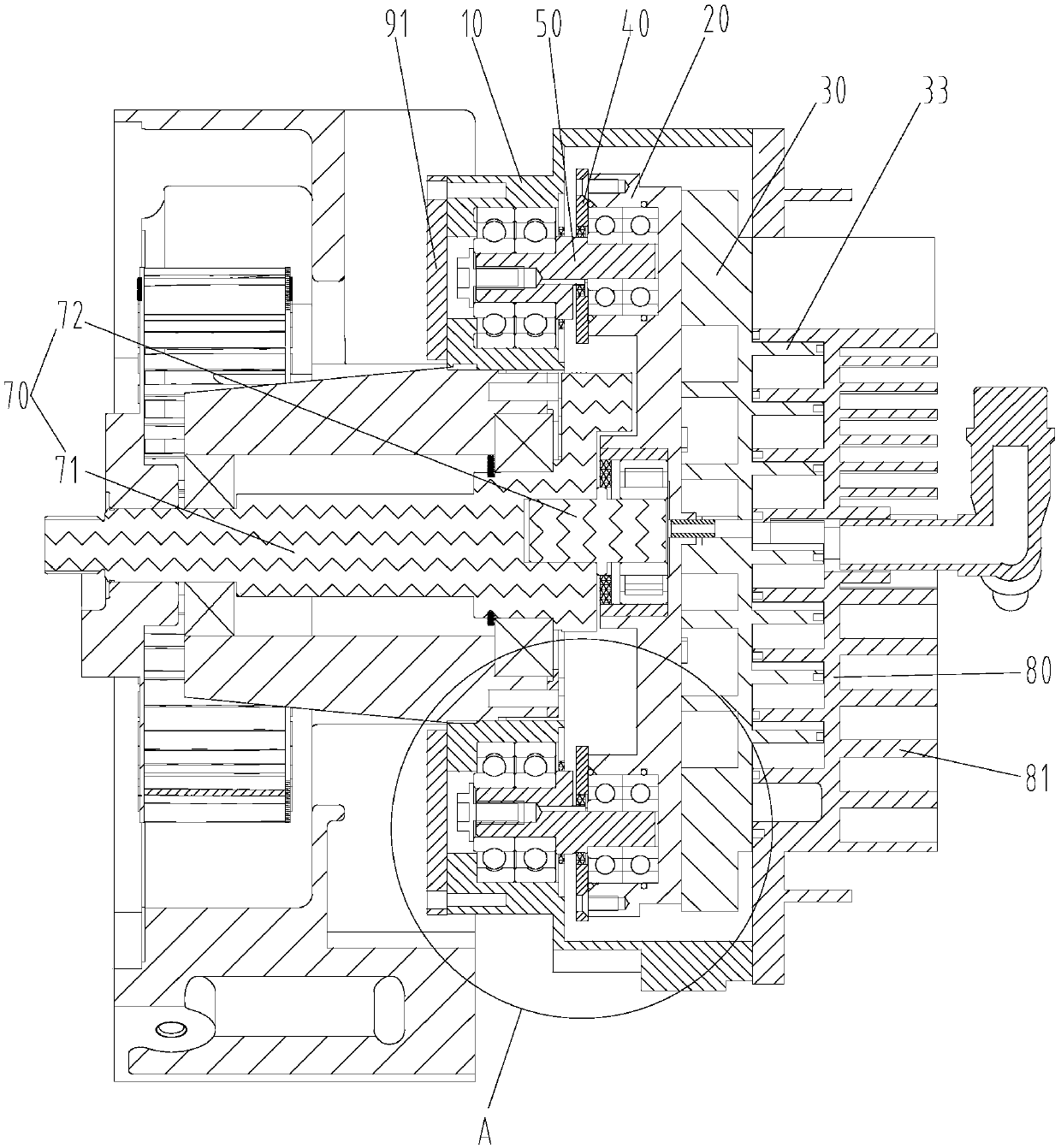

Crankshaft, scroll compressor and vehicle

ActiveCN108678955AAffects structural strengthReduce the chance of damageRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention provides a crankshaft, a scroll compressor and a vehicle. The crankshaft comprises a first rotating shaft, a second rotating shaft, a first shaft shoulder, a second shaft shoulder and anoil filling passage. The axis of the first rotating shaft and the axis of the second rotating shaft are parallel to each other. The first shaft shoulder and the first rotating shaft are coaxially arranged, and the second shaft shoulder and the second rotating shaft are coaxially arranged. The oil filling passage is arranged in the first rotating shaft, the first shaft shoulder and the second shaft shoulder. A first opening of the oil filling passage is formed in the first rotating shaft, a second opening of the oil filling passage is formed in the second shaft shoulder, and the second rotating shaft is a solid shaft. By the adoption of the technical scheme, the problems that an oil filling passage penetrating through a crankshaft is arranged in the crankshaft in the prior art, so that thestructural strength of the crankshaft is insufficient, damage to the crankshaft is caused easily and the normal operation of a scroll fluid machine is influenced are solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

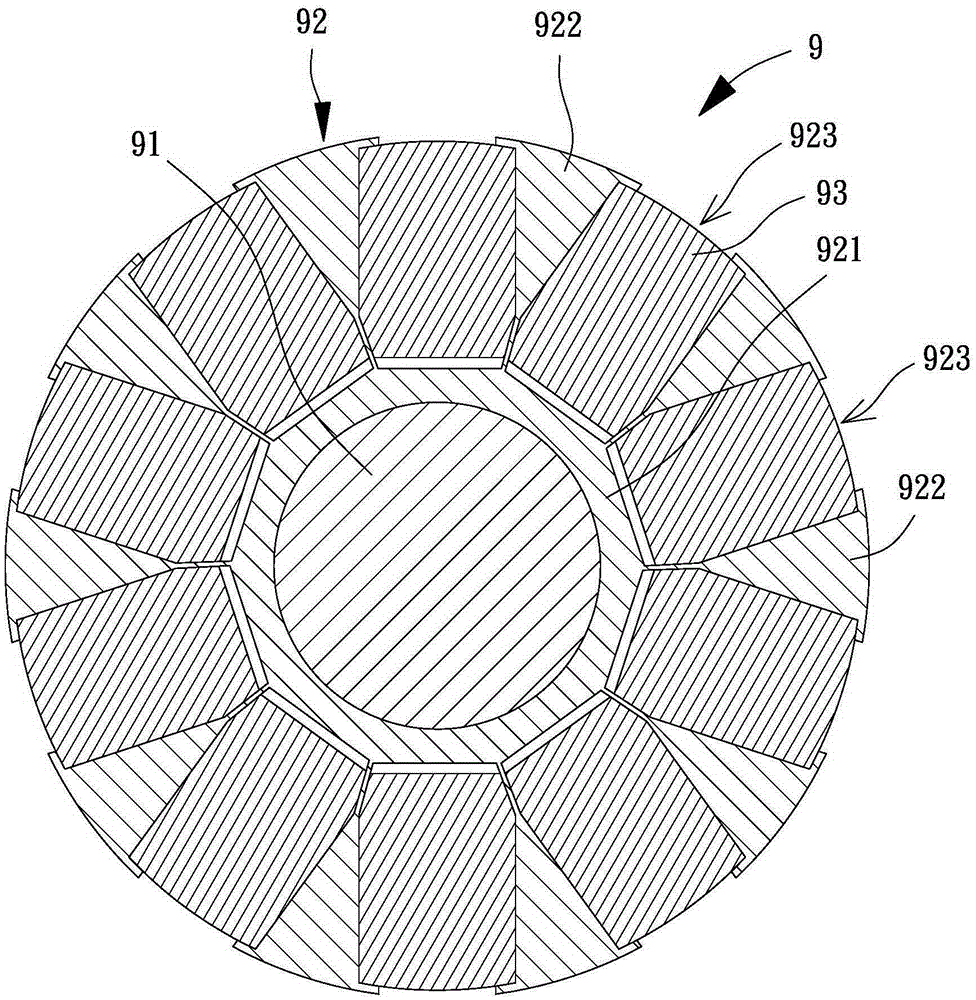

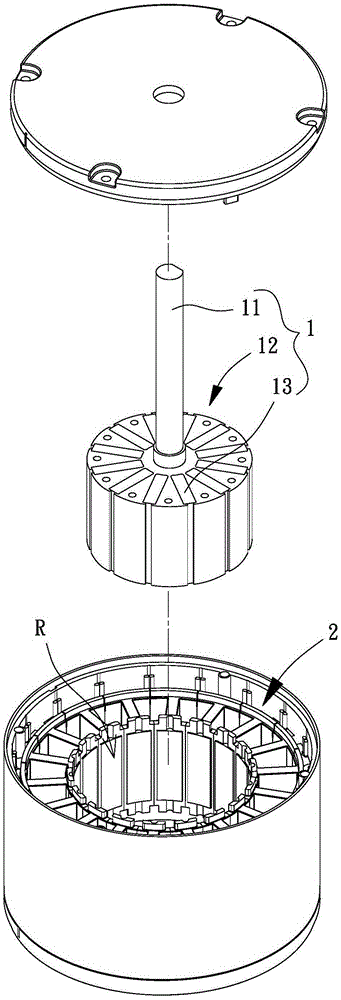

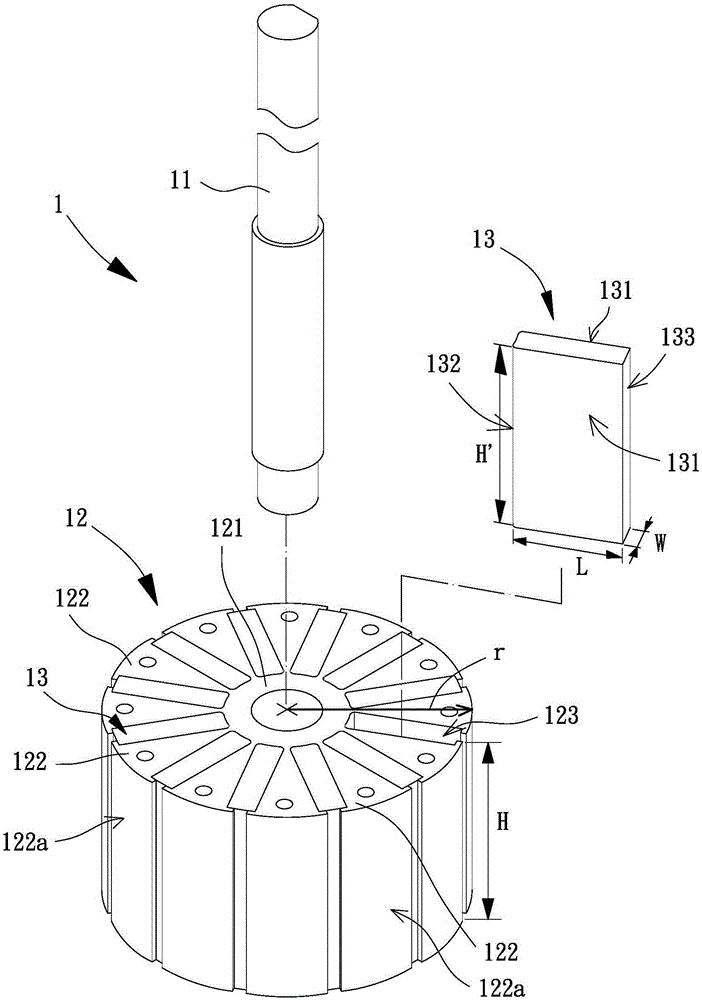

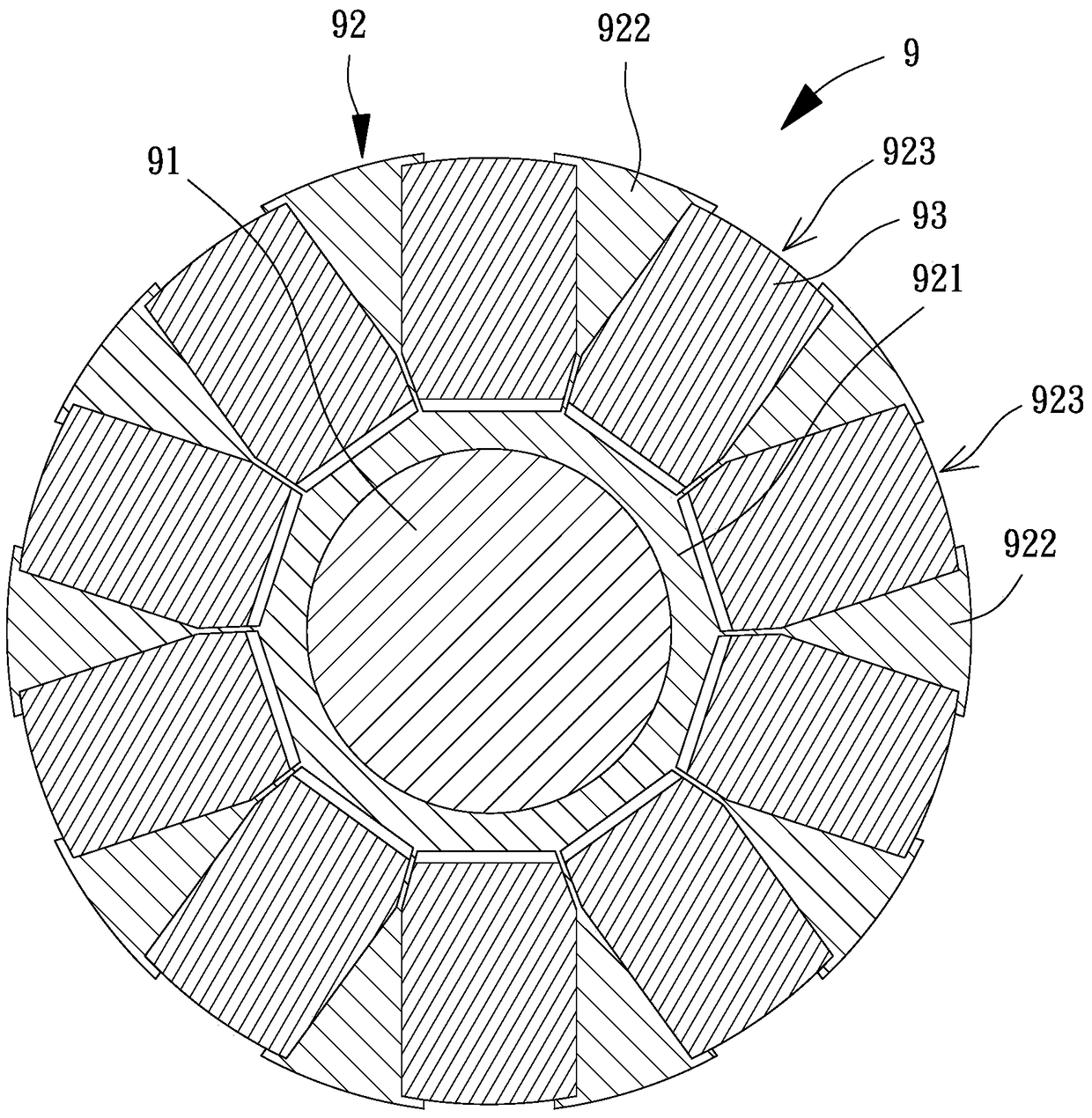

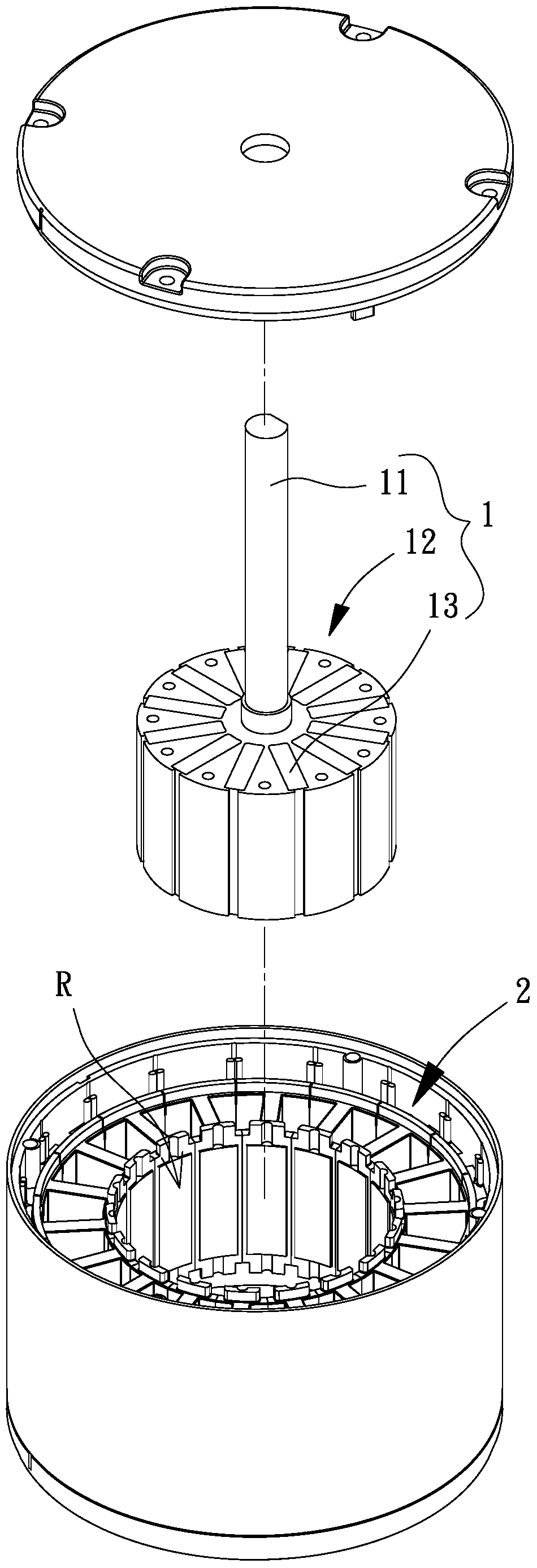

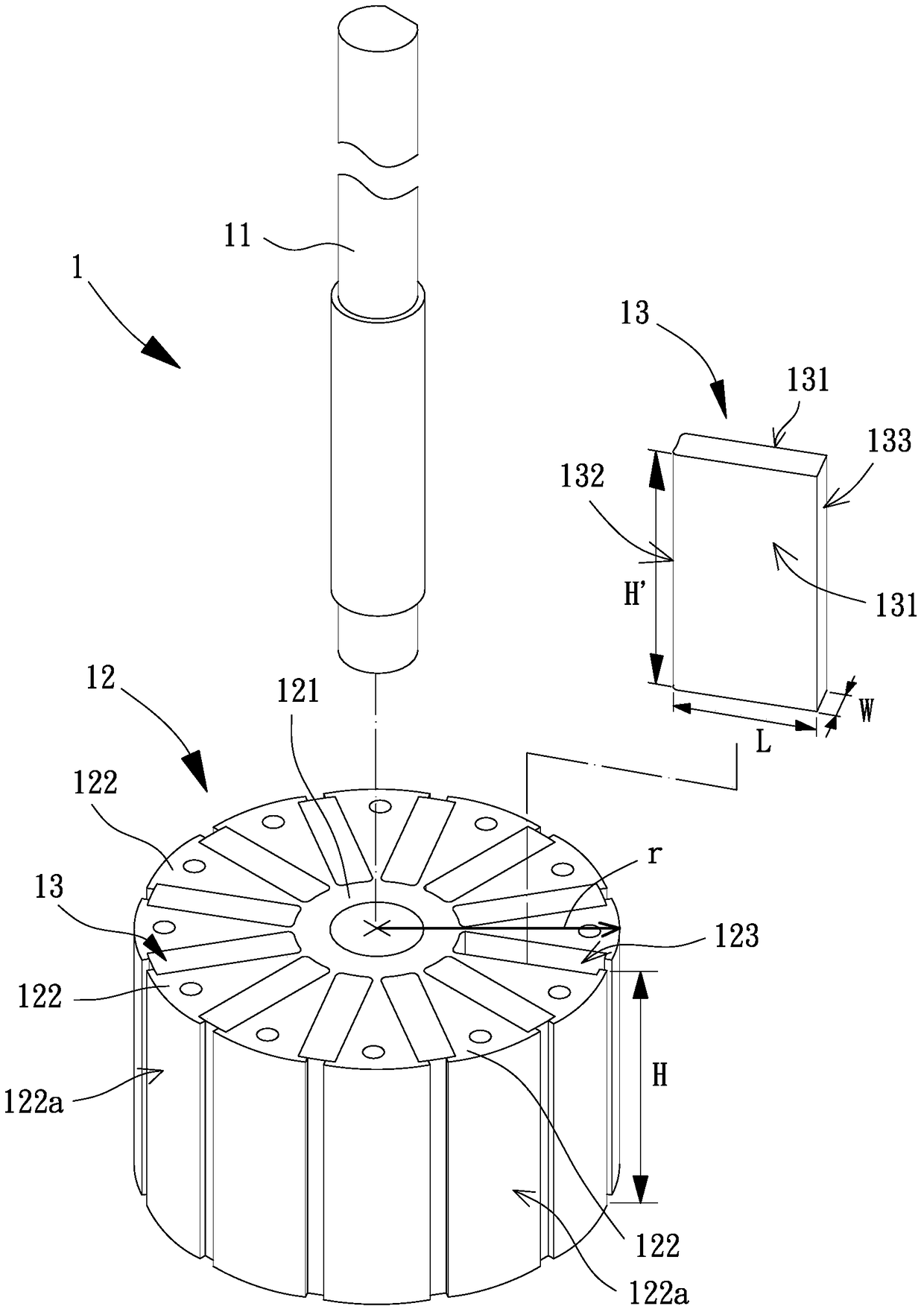

Inner Rotor Motor, Rotor Of Inner Rotor Motor And Size Selection Method Thereof

ActiveCN106560982AIncrease magnetic fluxAffects structural strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesSelection method

The present invention relates to an inner rotor motor, a rotor of the inner rotor motor and a size selection method thereof. The rotor comprises a rotating shaft, an iron core and a plurality of permanent magnets. The iron core comprises a magnet yoke part and a plurality of magnetic pole parts. The magnet yoke part is combined with the periphery of the above rotating shaft, the plurality of magnetic pole parts are arranged at the periphery of the magnet yoke part along a circumferential direction, and an accommodating groove is formed between two adjacent magnetic pole parts in the circumferential direction. The permanent magnets are arranged in the accommodating grooves respectively, wherein the magnetic pole end faces are formed at the sides of the magnetic pole parts far away from the rotating shaft, and the magnetic pole end faces of the magnetic pole parts extend in the circumferential direction to form a peripheral surface having an area. Each above permanent magnet comprises two first surfaces facing the magnetic pole parts, a second surface facing the above magnet yoke part and a third surface far away from the magnet yoke part, the two first surfaces, the second surface and the third surface have an area sum, and the ratio of the area sum and the area of the peripheral surface is between 0.15 and 0.36.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

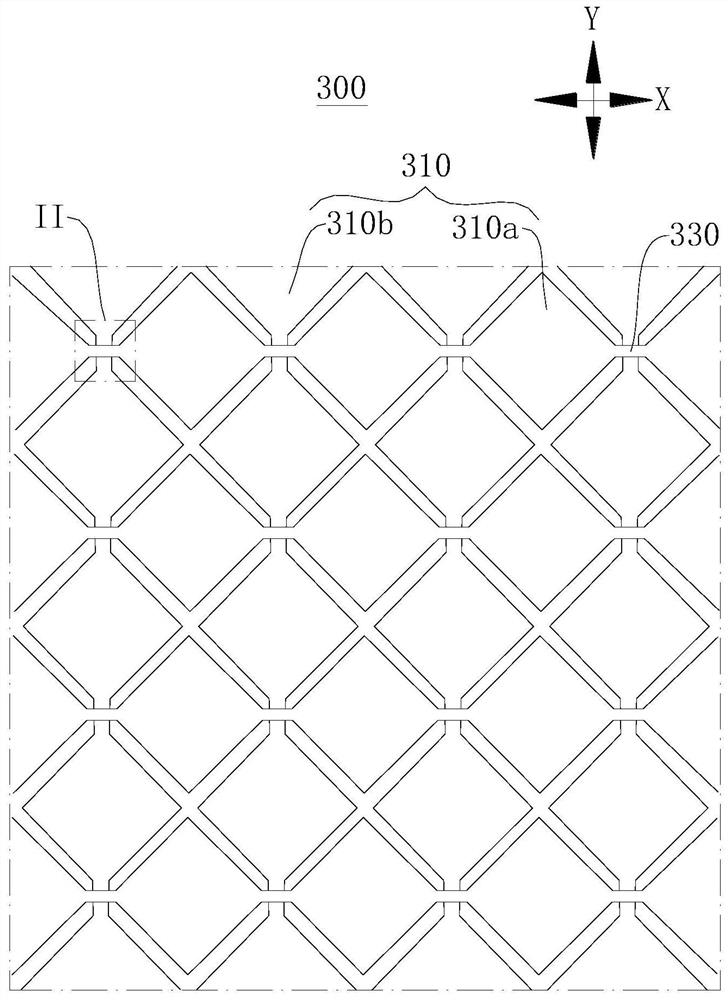

Display panel and display device

PendingCN113867572AAffect yieldImprove yieldInput/output processes for data processingDisplay deviceEngineering

The embodiment of the invention provides a display panel and a display device. The display panel comprises a substrate; a display device arranged on the substrate; and a touch control device arranged on the side, away from the substrate, of the display device, wherein the touch control device comprises a bridging layer, an insulating layer and a touch control electrode layer which are sequentially arranged in a stacked mode in the light emitting direction of the display panel, the bridging layer comprises a plurality of bridge-crossing electrodes, and the touch control electrode layer comprises touch control electrodes distributed in the first direction or the second direction; the second direction intersects with the first direction; each touch electrode comprises a touch electrode part, and the touch electrode part and the span bridge electrode are at least partially overlapped in the direction perpendicular to the plane where the display panel is located; each touch electrode part comprises a plurality of touch metal parts which form a metal grid shape and are electrically connected with one another, the bridge-crossing electrode comprises a plurality of bridge-crossing metal parts, and at least part of the touch metal parts extending in the same direction cover the bridge-crossing metal parts in the direction perpendicular to the plane where the display panel is located.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Steel structure of prestressed high-strength concrete pipe pile body

InactiveCN111764381AImprove pipe pile qualityAchieve protectionShaping reinforcementsBulkheads/pilesRebarLap joint

The invention discloses a steel structure of a prestressed high-strength concrete pipe pile body. The steel structure comprises a first pile head plate, wherein the side surface of the first pile headplate is fixedly connected with a tensioning positioning plate; a positioning groove is formed in the side surface of the first pile head plate; the inner wall of the positioning groove is in lap joint with a prestressed tendon pier head; the other end of the prestressed tendon pier head is fixedly connected with a prestressed steel bar; a spiral stirrup is arranged on the surface of the prestressed steel bar; the surface of the prestressed steel bar is sleeved with a steel sleeve hoop; and the right end of the prestressed steel bar is fixedly connected with a threaded sleeve. According to the steel structure of the prestressed high-strength concrete pipe pile body, a tensioning plate and a tensioning screw are arranged, the tensioning screw penetrates through the tensioning plate and isin threaded connection with the threaded sleeve, the gap between the threaded sleeve and the tensioning plate is adjusted through the tensioning screw, the tensioning plate and the tensioning positioning plate are parallel to each other, the situation that the structural strength of a pipe pile is affected due to the fact that the prestressed steel bar is stressed unevenly during tensioning is prevented, and therefore the effect of improving the quality of the pipe pile is achieved.

Owner:徐东新

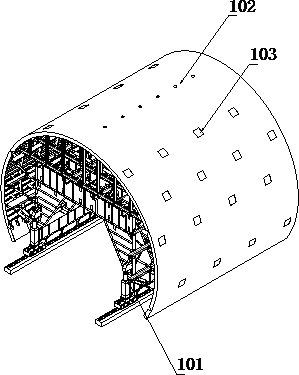

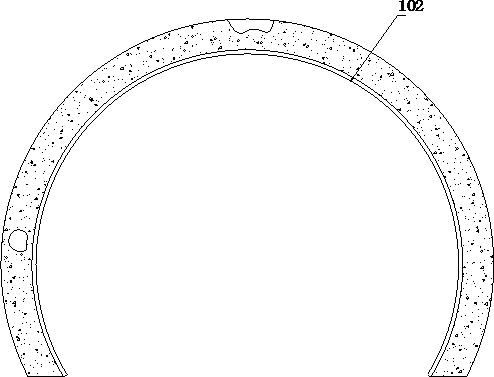

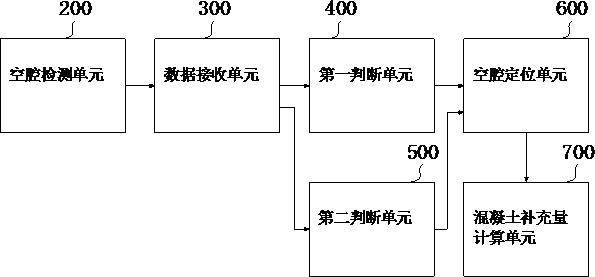

Intelligent monitoring system for tunnel power supply

ActiveCN113418483AAffects structural strengthMining devicesUnderground chambersMonitoring systemStructural engineering

The invention discloses an intelligent monitoring system for tunnel power supply. The intelligent monitoring system comprises a cavity detection unit used for collecting length information of a cavity; a first judgment unit used for screening and marking the cavity detection units located in the cavities influencing the concrete structure according to a first preset condition; a second judgment unit used for screening and marking the cavity detection units located in the cavities influencing the concrete structure according to a second preset condition; and a concrete supplement amount calculation unit used for acquiring the position information of the cavity detection units in the marked cavity detection unit set on the tunnel lining template and calculating the concrete supplement amount. The cavity detection unit is supplied with power to detect whether a cavity exists in concrete and whether the cavity affects the structural strength of the lining concrete layer, the position of the cavity is positioned, the concrete is supplemented and filled in time to make up defects, and the cavity affecting the structural strength of the lining concrete layer is avoided.

Owner:江苏高速公路信息工程有限公司

Elastic contact piece and electrical connector using the elastic contact piece

ActiveCN106025629BFit tightlyImprove reliabilityCoupling contact membersElectrical conductorElectrical connector

The invention relates to the field of electric connectors, in particular to an elastic contact part and an electric connector employing the same. The elastic contact part comprises a tail conductor, a contact part and an elastic part, wherein the elastic part is used for providing the contact part with elastic force; a contact pin extending along the axial direction is arranged at the front end of the tail conductor; the contact part comprises a contact part body; a contact end is arranged at the front end of the contact part body; a shrinking structure capable of extending along the axial direction of the contact pin and elastically shrinking along the radial direction of the contact pin is arranged at the rear part of the contact part body; and the shrinking structure and the contact pin are in elastic sliding contact. The contact pin extending along the axial direction is arranged at the front end of the tail conductor; and the shrinking structure capable of shrinking along the radial direction of the contact pin is arranged at the rear end of the contact part body; and the contact part sleeves the contact pin through the shrinking structure on the contact part body, so that the contact part and the contact pin are tightly laminated; and the electric connection reliability between the contact part and the contact pin is strengthened.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

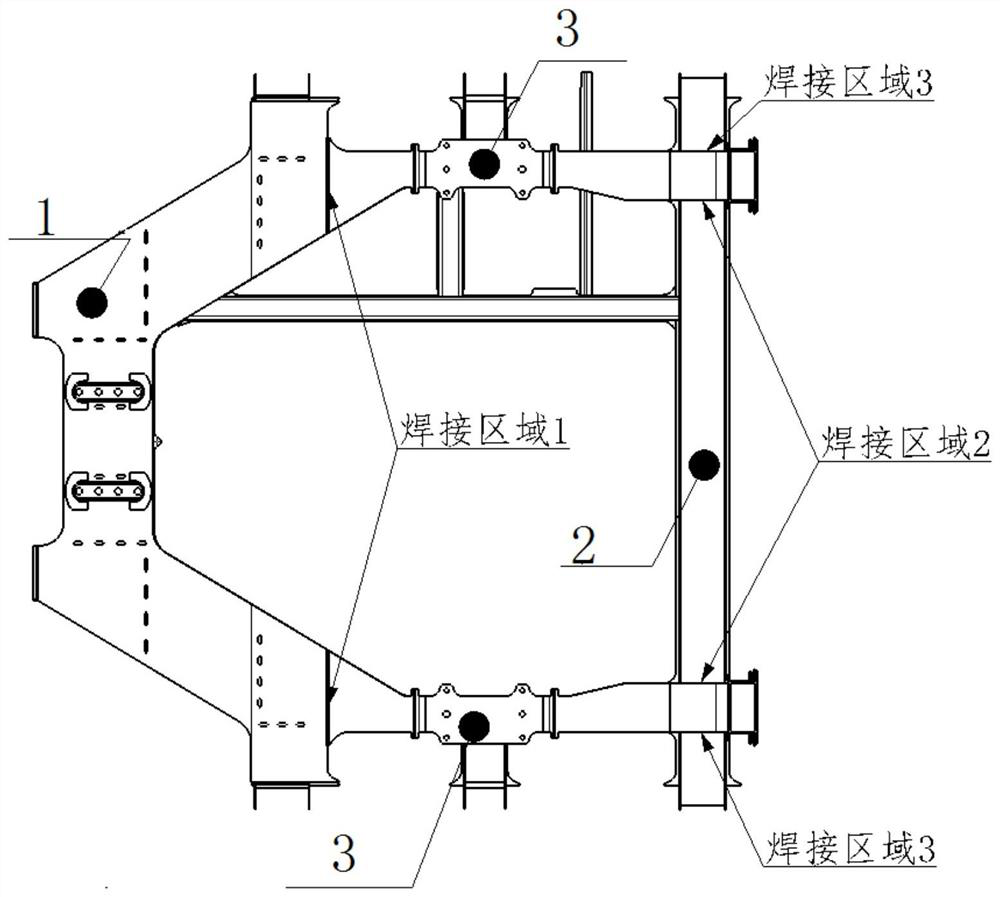

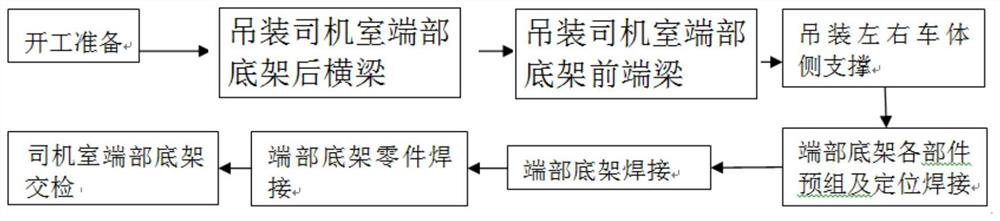

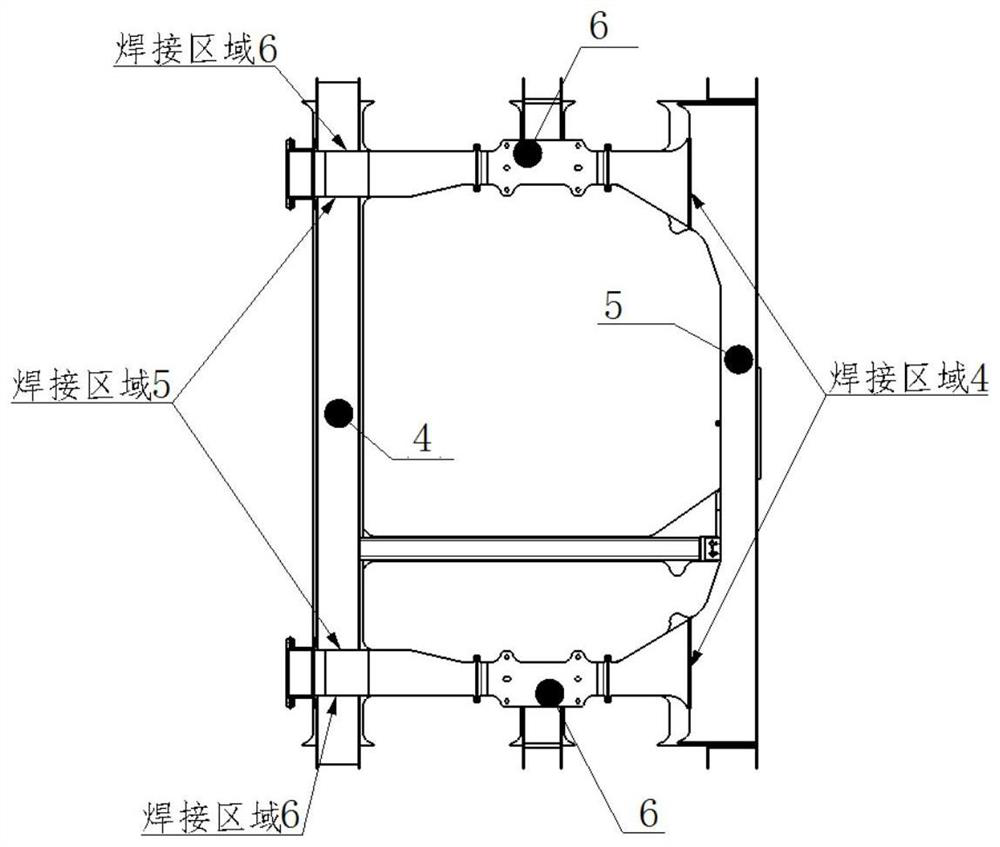

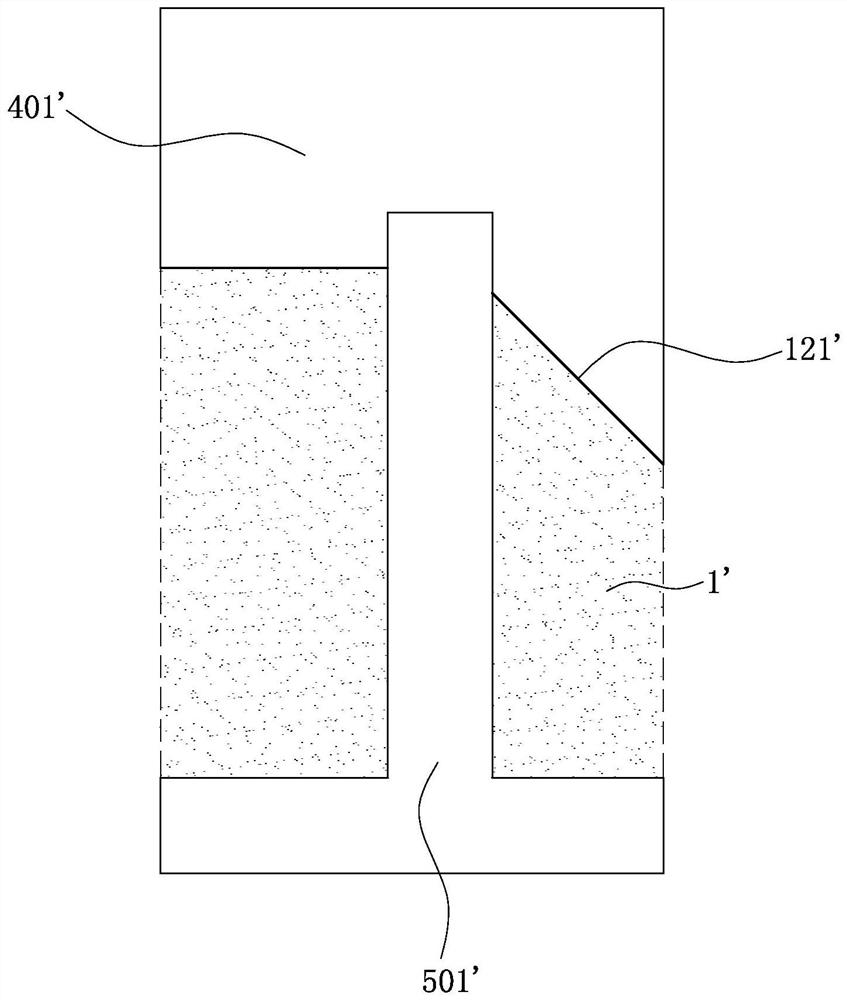

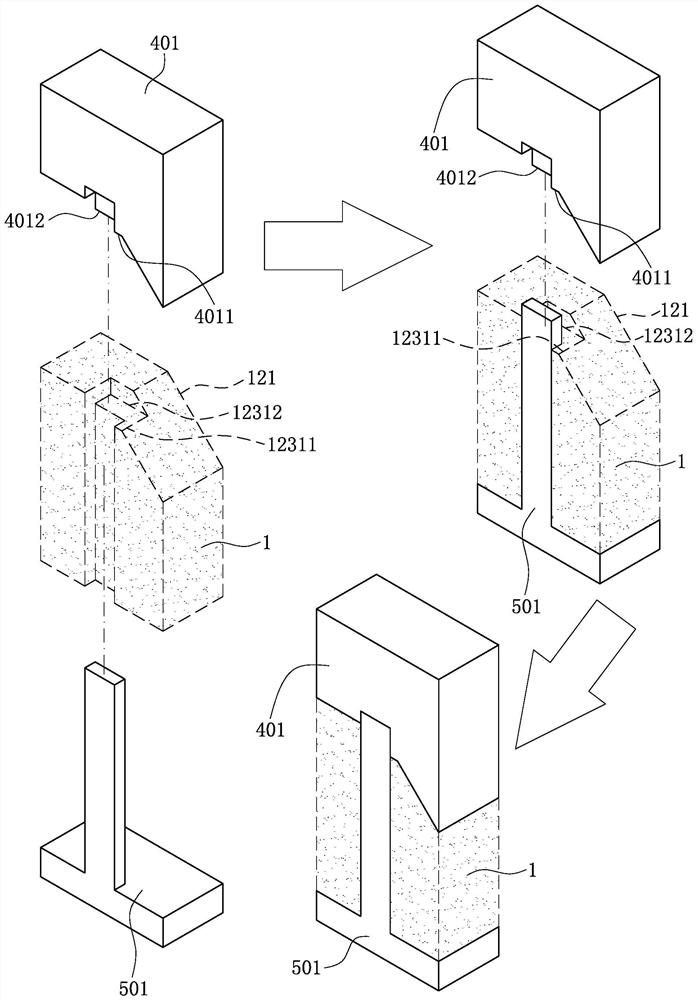

Car body underframe assembly and its welding process

ActiveCN110860770BStructural strength has no effectStructural Strength EffectArc welding apparatusUnderframesWelding processAutomotive engineering

The invention discloses a car body underframe assembly and its welding process. The process adopts a modularized production method to complete the assembly and welding of the driver's cab end underframe and the two-position end underframe respectively, and then hoist the above two The end chassis and the side beams of the chassis on both sides are attached to the base plate to complete the pre-assembly and positioning of the chassis frame; finally, parts are added on the basis of the chassis frame, and the front welding and reverse welding are completed successively to form the vehicle. Body underframe assembly; the welding is all using CMT pulse cold transition process. The present invention adopts a modular process, divides the bottom frame into three large modules, and each large module has different small modules, and carries out blanking, processing and distribution of materials according to the modules. The site is clean and the process is clear, effectively avoiding The phenomenon of wrong installation and missing installation. The invention also discloses a vehicle body underframe assembly.

Owner:安徽雷尔伟交通装备有限公司

Electric connector

The invention discloses an electric connector, which is characterized in that an insulating body is provided with a plugging groove, a butt joint element is inserted into the plugging groove along the insertion direction, and the insulating body is provided with a side wall at one side of the plugging groove; the side wall is provided with a guide inclined surface, a butt joint surface connected with the guide inclined surface and a plurality of grooves which are concavely arranged from the guide inclined surface and the butt joint surface along the insertion direction, the guide inclined surface is provided with a first boundary connected with the butt joint surface and a second boundary which is arranged at an interval with the first boundary, and the grooves are provided with inner bottom surfaces connected to the guide inclined surface; a terminal groove extends from each groove along the insertion direction, each terminal groove is provided with an opening positioned on the inner bottom surface, the inner bottom surface is provided with a first surface positioned on one side of the opening and two second surfaces positioned on two opposite sides of the opening, the first surface is provided with a first edge connected to the guide inclined surface, the opening is provided with a second edge connected to each second surface, and the first edge and the second edge are arranged along the insertion direction. The first edge is located between the first boundary and the second boundary, and the second edge intersects with an extension line of the first boundary.

Owner:中山得意电子有限公司

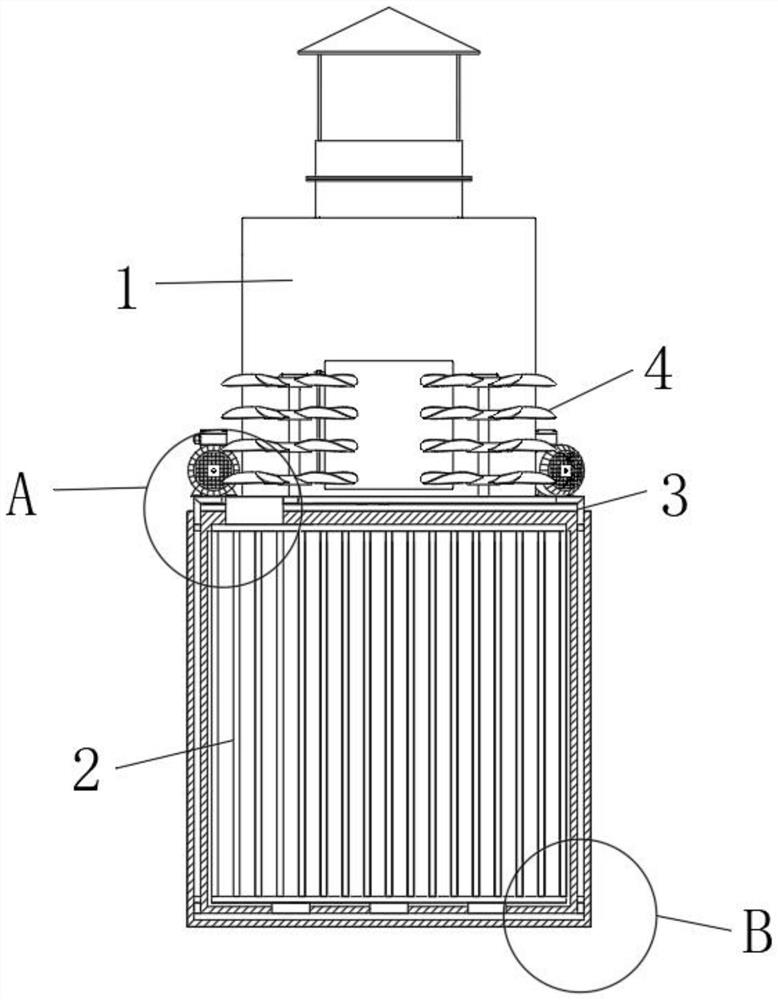

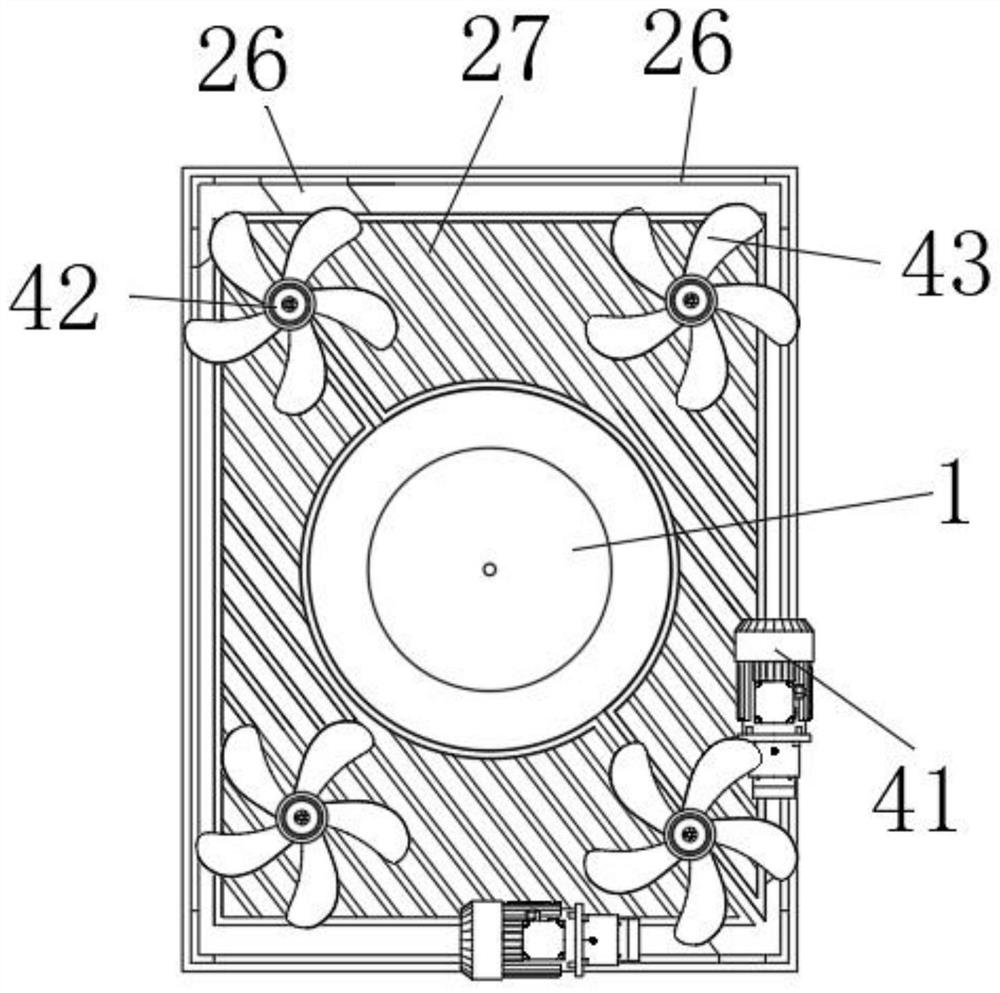

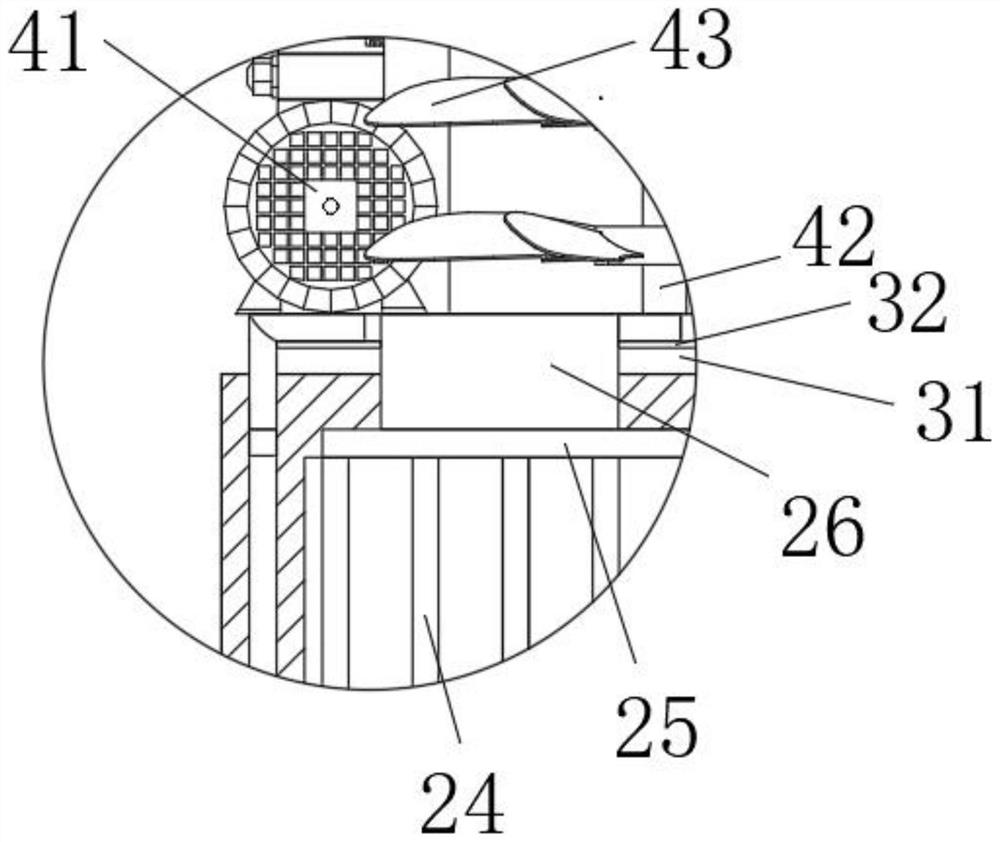

Rapid cooling system for plateau household garbage incinerator

PendingCN113701158ARapid coolingAffect the service lifeDomestic cooling apparatusIncinerator apparatusThermodynamicsProcess engineering

The invention relates to the field of rapid cooling of garbage incinerators, in particular to a rapid cooling system for a plateau household garbage incinerator. The rapid cooling system comprises the incinerator, an incineration chamber is arranged in the incinerator, two heat absorption units are fixedly mounted in the incinerator, and a heat dissipation unit and an auxiliary unit are further fixedly mounted at the top of the incinerator. When cooling is needed, a pump machine can push a heat absorption solution to flow to a heat dissipation pipe network in the incinerator, heat dissipation is carried out through an extension piece and the heat dissipation unit, and the incinerator is rapidly cooled, so that the temperature can return to the normal interval; through a liquid storage pool and flow dividing pipes, when incineration operation is carried out in the incinerator, the heat conducted by incinerated objects can be absorbed, the situation that the service life and the structural strength of the inner wall of the incinerator are affected due to the fact that the temperature in the incinerator rises sharply is avoided, the flow dividing pipes are distributed on the outer side of the incineration chamber in the incinerator and can better absorb heat of the incinerator, and the internal structure of the incinerator is prevented from being damaged by temperature difference zones formed in all positions of the inner wall of the incinerator due to sharp temperature drop.

Owner:四川正一环境科技有限公司

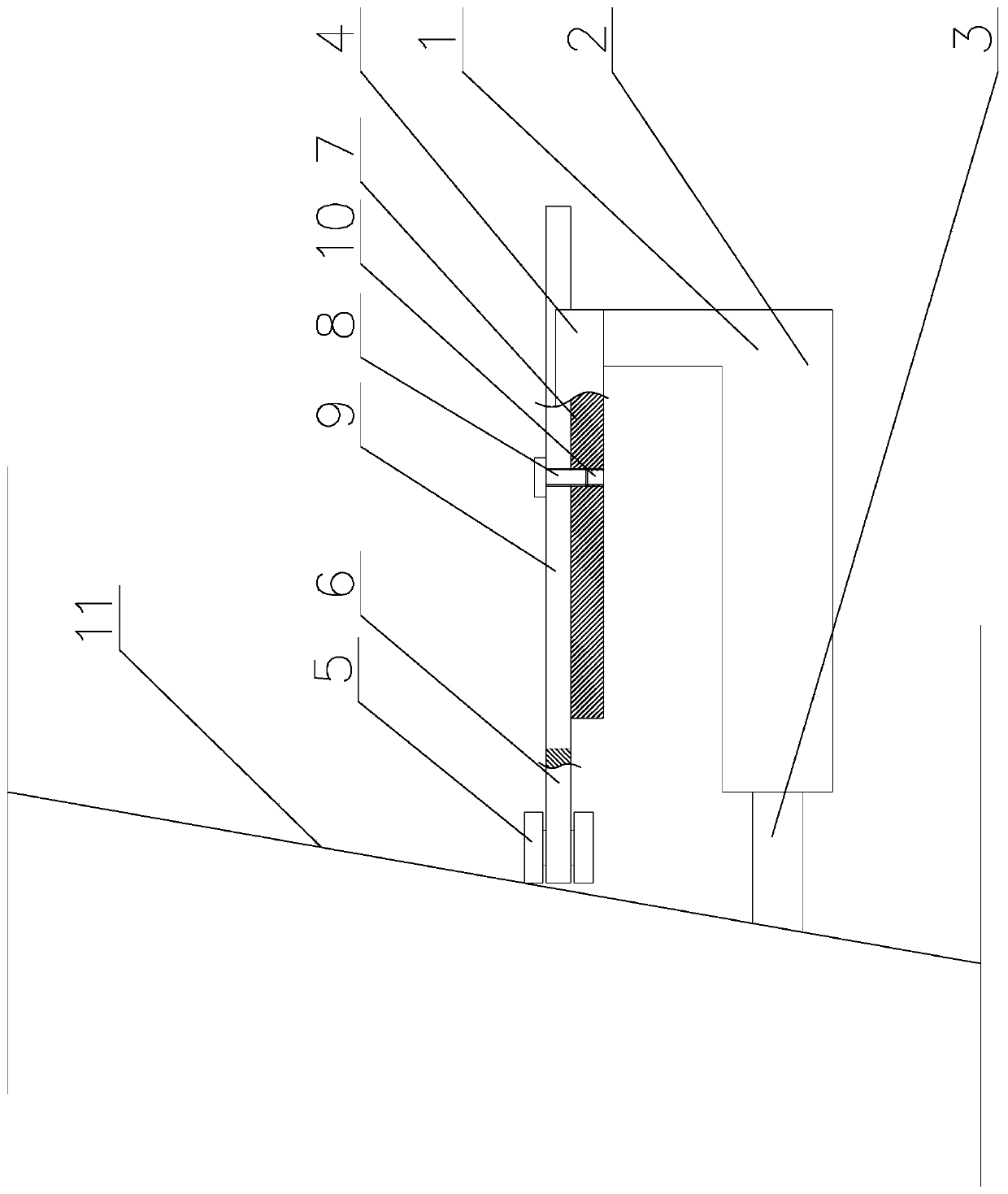

A pressurized solar water heater system and its installation process

ActiveCN112066570BImprove convective heat transfer efficiencyStrong pressureSolar heating energyFluid circuit connectionsWater storageWater storage tank

The invention relates to a pressurized solar water heater system and its installation process, which includes a heat collecting header, a support, and a plurality of heat collecting vacuum tubes placed between the heat collecting header and the support, and also includes a water storage tank and a water storage tank. The heat exchange tube inside, the heat exchange tube is placed at the bottom of the water storage tank, one end of the heat collection vacuum tube is sealed with a heat collection copper core, and the heat collection copper core extends into the heat collection header, and the heat collection header is equipped with a U-shaped The two ends of the U-shaped tube extend out of the heat collecting header and are connected with the first circulation pipe and the second circulation pipe correspondingly. The first circulation pipe and the second circulation pipe are connected with the water storage tank and communicate with the heat exchange tank; the present invention The utility model has the following advantages: while ensuring the convective heat transfer efficiency in the water storage tank, the structural strength of the heat transfer tank is improved.

Owner:JIANGSU YUPU SOLAR ENERGY

Process for breaking cast-in-place pile through ring cutting method

InactiveCN110700258AAvoid structural strengthAffects structural strengthBulkheads/pilesRebarKnife blades

The invention discloses a process for breaking a cast-in-place pile through a ring cutting method. The process comprises the construction steps that firstly, construction preparation is made; secondly, machines and tools are prepared; thirdly, the elevation is measured, and locating is conducted; fourthly, ring cutting construction is conducted; fifthly, a main reinforcement is inclined toward theouter side; sixthly, iron wedges are driven in around a pile head; seventhly, the pile head is lifted away from a foundation pit by a crane; eighthly, an inclined reinforcement is recovered; and ninthly, a site is cleaned. According to the provided process for breaking the cast-in-place pile through the ring cutting method, the ring cutting depth is located effectively through novel ring cuttingequipment, a blade can be prevented from cutting the main reinforcement in the pile head, and meanwhile, the conditions that in a traditional process, an air compressor is adopted, and structural strength of the pile head is influenced are avoided.

Owner:常州市市政建设工程集团有限公司

Compressor and heat pump equipment

PendingCN112360746AReduce opening depthGuaranteed structural strengthHeat pumpsRotary/oscillating piston pump componentsEngineeringInjection air

The invention provides a compressor and heat pump equipment. The compressor comprises at least one air cylinder assembly, a supporting piece, an air injection channel and the one-way valve, each air cylinder assembly is provided with an exhaust cavity, and a first mounting groove is formed in the end face of each air cylinder assembly; the supporting piece is arranged on one side of one air cylinder assembly in the at least one air cylinder assembly, a second mounting groove is formed in the end face of the supporting piece, the second mounting groove and the first mounting groove are oppositely formed, and the first mounting groove and / or the second mounting groove communicate / communicates with the exhaust cavity; the air injection channel is arranged on the at least one air cylinder assembly and / or the supporting piece, and the air injection channel can communicate with the first mounting groove and the second mounting groove; and the one-way valve is arranged in the first mounting groove and / or the second mounting groove. An air supplementing cavity is partially formed in the air cylinder assembly and partially formed in the supporting piece, the forming depth of the first mounting groove and the forming depth of the second mounting groove cannot be too large, the structural strength of the air cylinder assembly and the supporting piece are guaranteed, the stability is high,and use is safe and reliable.

Owner:ANHUI MEIZHI PRECISION MFG

Inner Rotor Motor, Rotor of Inner Rotor Motor and Selection Method of Its Size

ActiveCN106560982BIncrease magnetic fluxAffects structural strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesControl theory

The present invention relates to an inner rotor motor, a rotor of the inner rotor motor and a size selection method thereof. The rotor comprises a rotating shaft, an iron core and a plurality of permanent magnets. The iron core comprises a magnet yoke part and a plurality of magnetic pole parts. The magnet yoke part is combined with the periphery of the above rotating shaft, the plurality of magnetic pole parts are arranged at the periphery of the magnet yoke part along a circumferential direction, and an accommodating groove is formed between two adjacent magnetic pole parts in the circumferential direction. The permanent magnets are arranged in the accommodating grooves respectively, wherein the magnetic pole end faces are formed at the sides of the magnetic pole parts far away from the rotating shaft, and the magnetic pole end faces of the magnetic pole parts extend in the circumferential direction to form a peripheral surface having an area. Each above permanent magnet comprises two first surfaces facing the magnetic pole parts, a second surface facing the above magnet yoke part and a third surface far away from the magnet yoke part, the two first surfaces, the second surface and the third surface have an area sum, and the ratio of the area sum and the area of the peripheral surface is between 0.15 and 0.36.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

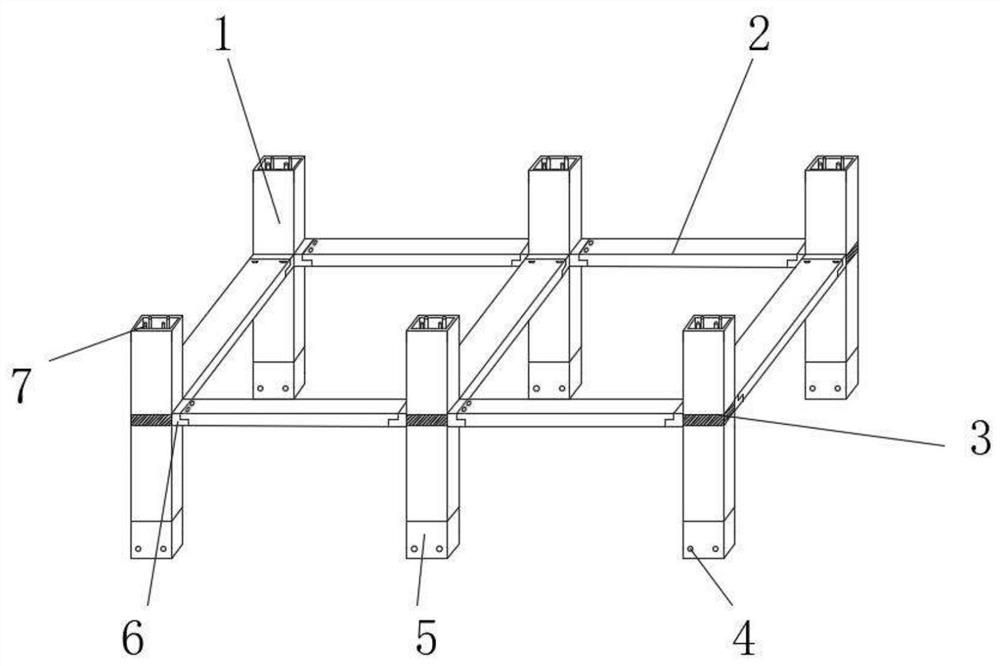

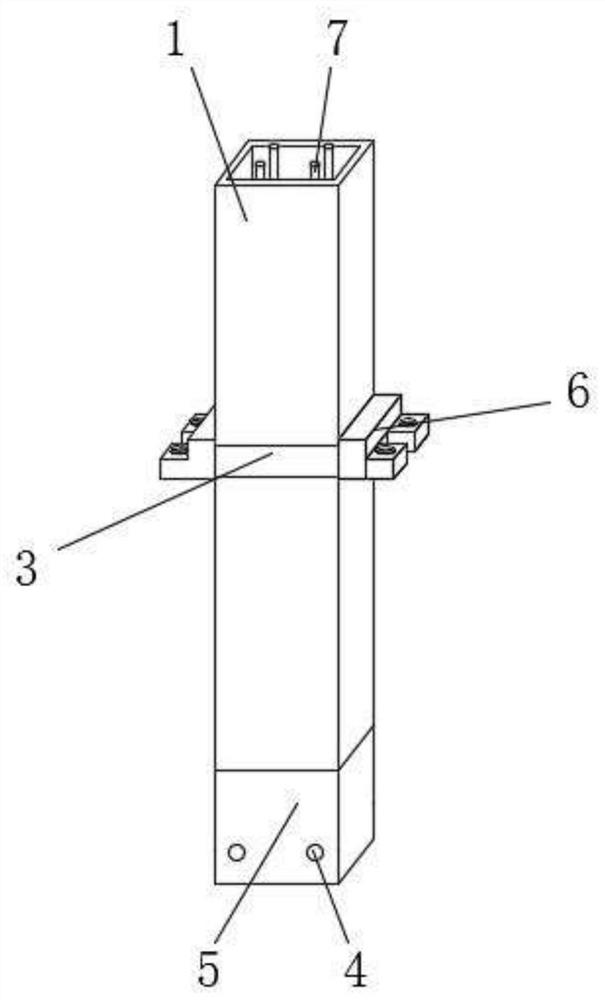

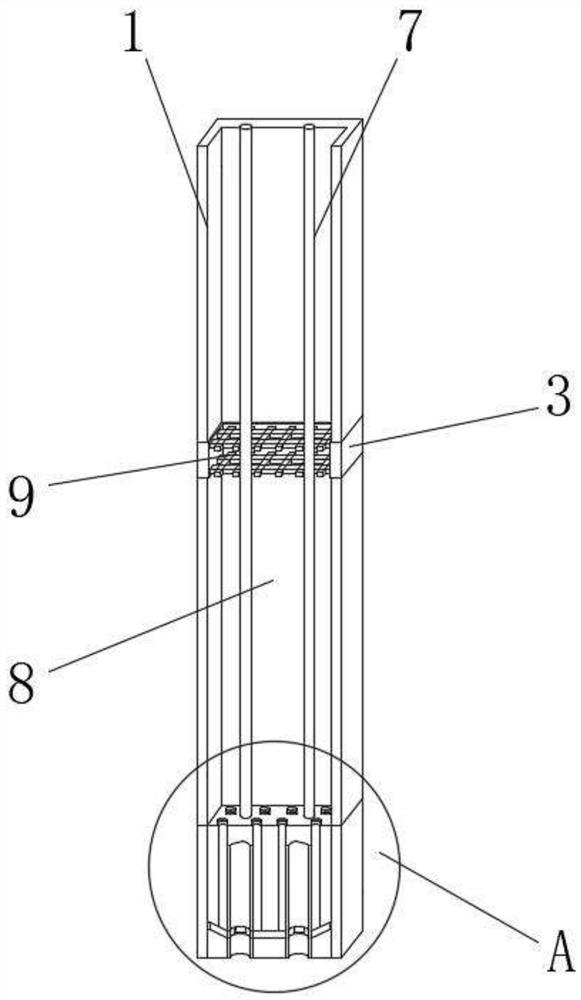

Prefabricated building frame and rapid connecting method thereof

The invention provides a prefabricated building frame and a rapid connecting method thereof. The building frame comprises at least four sets of supporting column bodies; connecting steel plates are connected with the middles of the supporting column bodies in a penetrating mode; supporting corners are fixedly connected with the side end faces of the connecting steel plates; each supporting cornercomprises a supporting leg body, a connecting platform, a limiting groove and a second threaded hole; the connecting platforms are fixedly connected with one sides of the side end faces of the supporting leg bodies; the limiting grooves are formed in the middles of the connecting platforms; the second threaded holes are formed in the upper end faces of the connecting platforms; a bearing cross beam is fixedly connected between the supporting corners; the bearing cross beam comprises a bearing cross beam body, bolt grooves, a first threaded hole, a limiting column, and a hanging ring; and the bolt grooves are formed in the four corners of the upper end face of bearing cross beam body. The prefabricated building frame is simple to build, stable in structure, high in structural strength and applicable to quick building of lower-layer building frames by the aid of prefabricated building principles.

Owner:中民筑友房屋科技(石首)有限公司

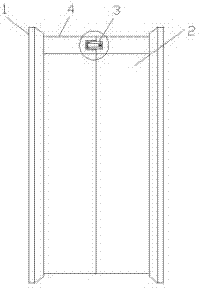

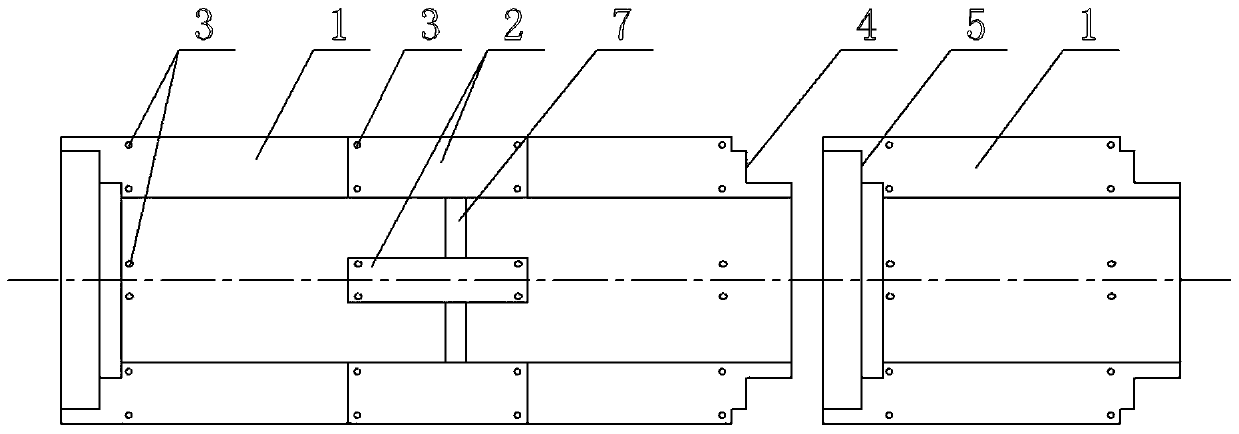

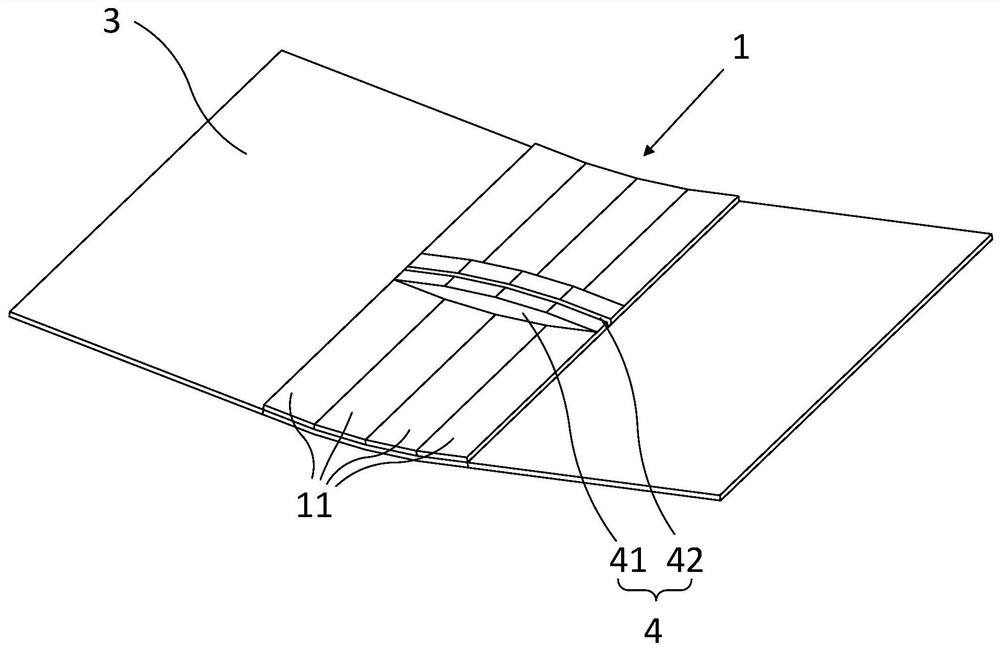

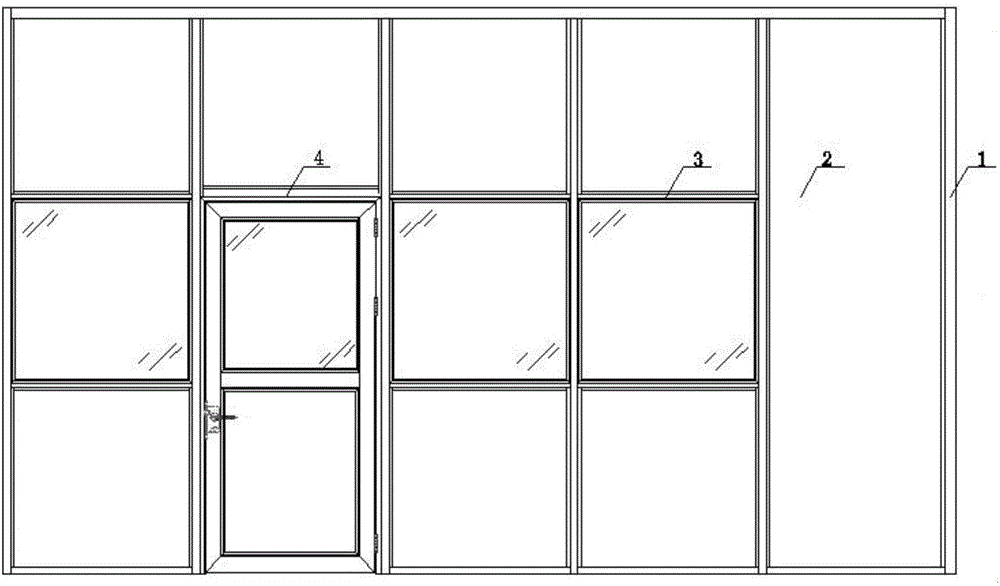

Clean partition wall system for electronic industry

InactiveCN106193380ANo impact on structural strengthAffects structural strengthWallsElectronic industryWall plate

The invention discloses a clean partition wall system for electronic industry. The clean partition wall system comprises upright posts (1), modular wall boards (2), modular single-layer windows (3) and modular finished product door laves (4), and is characterized in that the upright posts (1) are connected with the modular wall boards (2) through a framework; each modular single-layer window (3) is arranged on the corresponding modular wall board (2); and the modular wall boards (2) are connected with the modular finished product door leaves (4) through a framework. The clean partition wall system has the advantages that an upright post type structure is used; the upright posts are in a completely independent state; the adjacent board is not influenced at all when any one board is dismounted; and the structure strength of the whole partition wall system is also not influenced at all.

Owner:KUNSHAN MAX METAL

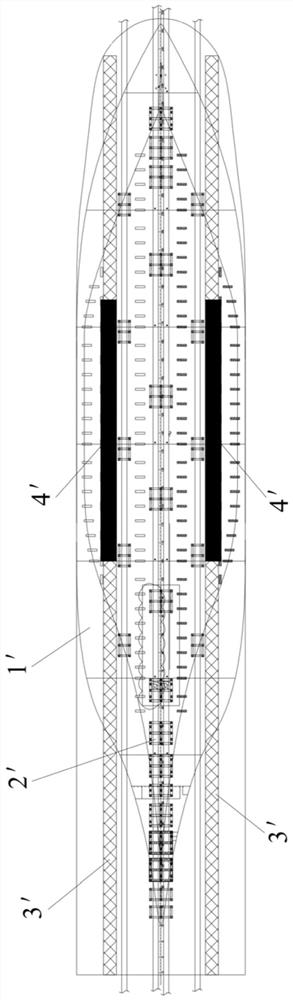

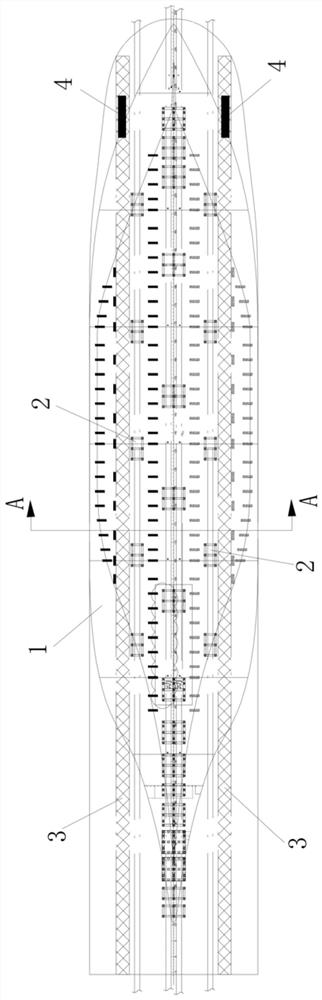

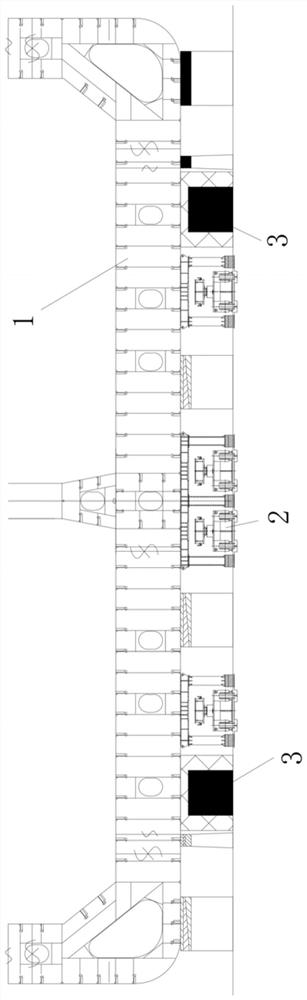

An emergency method and emergency equipment for power unit failure of a ship-moving trolley

ActiveCN109204109BSolve the problem of high water costAffects structural strengthSlipwaysVessel designingTruckPower apparatus

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com