Single crystal silicon refining production process and refining device thereof

A refining device and production process technology, which is applied in the field of single crystal silicon refining production process and its refining device, can solve the problems that the tail growth process cannot be accurately controlled, slow cooling, insufficient crystallization strength, etc., to ensure the necking growth process, Accurately generate speed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

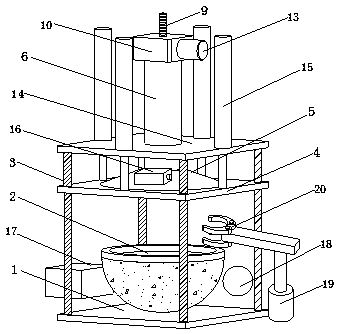

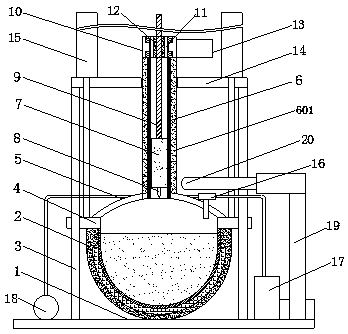

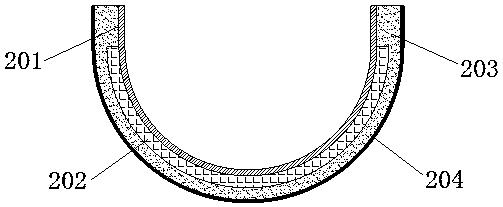

[0033] see Figure 1-4 , the present invention provides the following technical solutions: a single crystal silicon refining production process, including the following steps:

[0034] S1, feeding process: put the accurately weighed polysilicon raw materials and doping materials into the heating tank according to the ratio set by the process. The type of doping materials depends on the N or P type of resistance, and the content of doping materials depends on the conductivity. and purity requirements are determined, and the types of doping materials include boron, phosphorus, antimony, and arsenic;

[0035] S2, melting process: After adding the polysilicon raw material into the quartz crucible, the crystal growth furnace is closed and evacuated, and then filled with high-purity argon to maintain a certain pressure range, and then turn on the power of the graphite heater to heat until the polysilicon is melted Above the temperature, the mixture of polysilicon raw material and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com