Buffer sleeve and working cylinder of hydraulic device using buffer sleeve

A technology of hydraulic devices and buffer sleeves, applied in fluid pressure actuators, mechanical equipment, etc., can solve problems such as insufficient oil supply to the piston chamber, insufficient starting force of piston 2, unstable closing time, etc., to improve the starting force , Increase movement speed, increase the effect of starting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

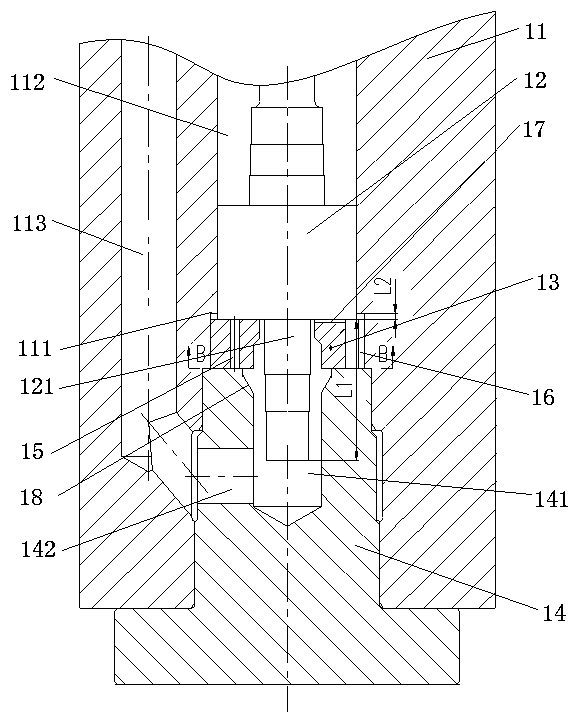

[0041] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

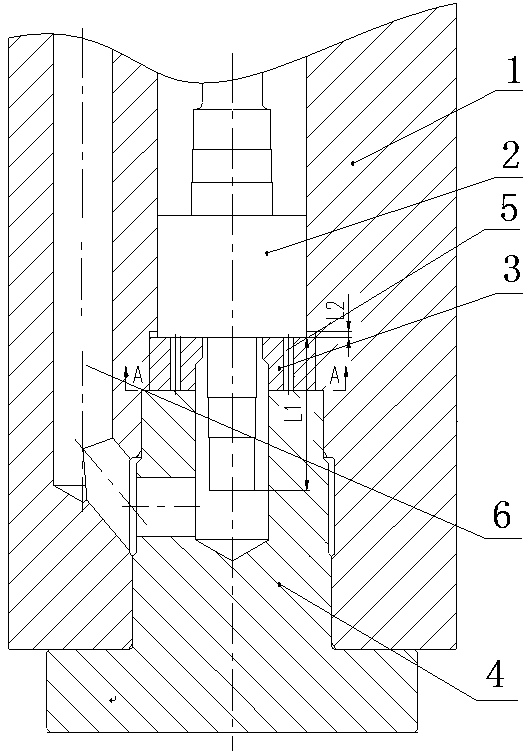

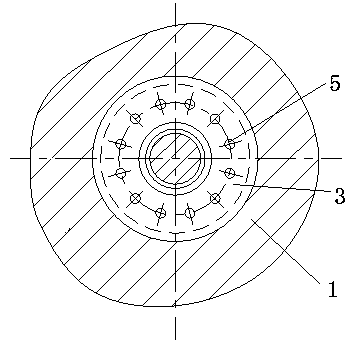

[0042] An embodiment of the working cylinder of the hydraulic device of the present invention, such as image 3As shown, the working cylinder of the hydraulic device includes a cylinder body 11 and a piston 12. The cylinder body 11 is provided with a piston chamber 112. The piston 12 is movably assembled in the piston chamber 112 along the axial direction of the cylinder body 11. The piston chamber 112 is used to communicate with the piston. The inner wall of one end corresponding to the buffer stroke end of 12 is provided with a stop step 111, and the end of this end is provided with a plug 14, and the plug 14 is connected with the cylinder body 11 by bolts. A center hole 141 for inserting the buffer shaft 121 of the piston 12 is provided at the center of the plug 14 .

[0043] The working cylinder of the hydraulic device also includes a buffer sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com