Process for breaking cast-in-place pile through ring cutting method

A cast-in-place pile and girth cutting technique, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of low construction efficiency, affecting the overall durability of the structure, increasing noise and dust pollution, and avoiding structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the technical solutions provided by the present invention more clearly, the present invention will be further described below in conjunction with specific examples.

[0027] A kind of circumcision method provided by the present invention breaks cast-in-situ pile technology, its construction steps;

[0028] The first step is construction preparation, and the work preparation inside the foundation pit is carried out;

[0029] The second step is to prepare the equipment, adjust the construction equipment properly, and prepare for operation;

[0030] The third step is to measure the elevation and position, mark the design elevation of the pile head, and prepare for the construction work;

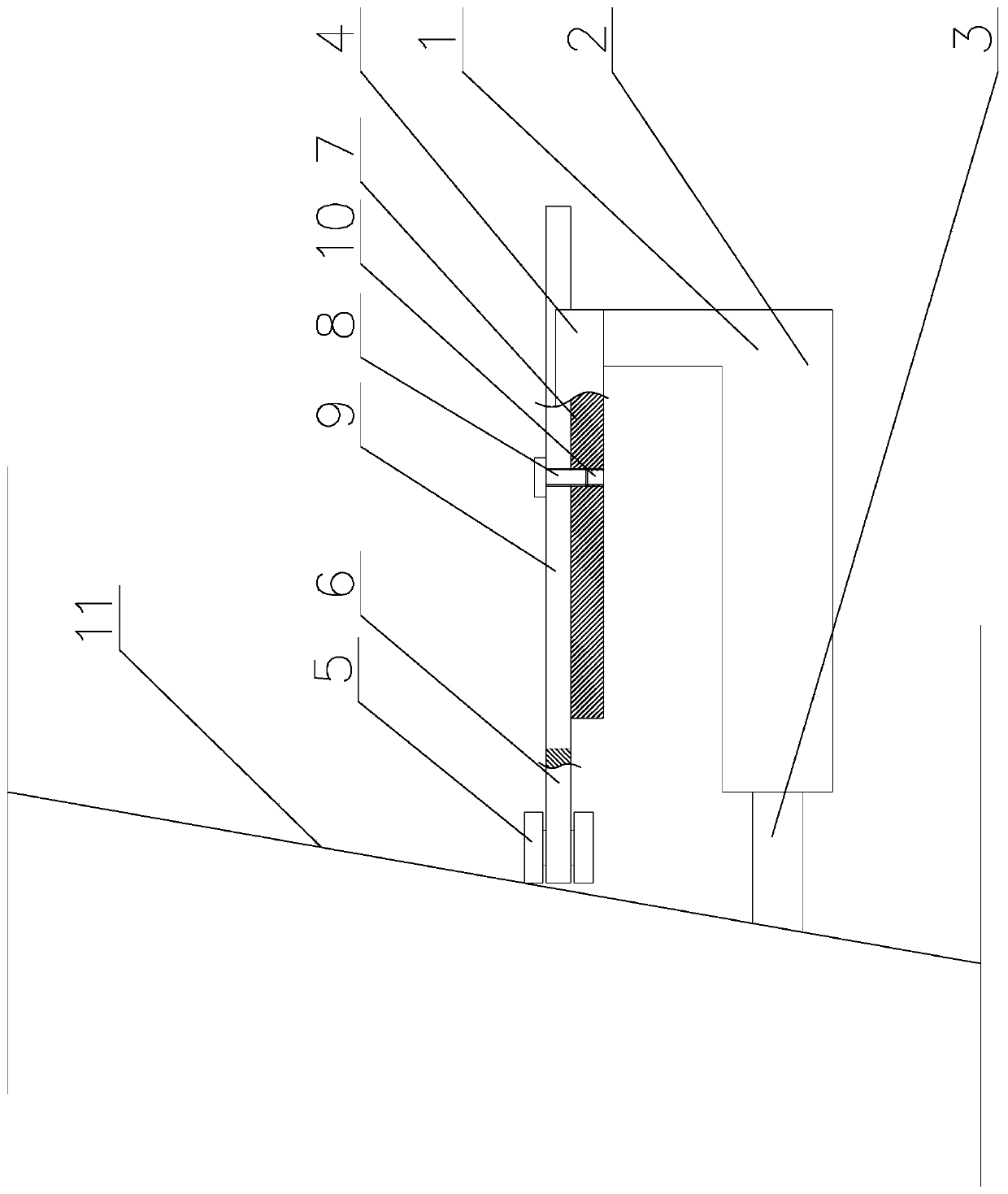

[0031] The fourth step is ring cutting construction. Ring cutting equipment is used to cut the pile head at the design elevation, and at the same time, the concrete is chiseled on the cutting seam to expose the steel bars;

[0032] The fifth step is to tilt the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com