Ultrahigh-pressure artificial miscellaneous grains and making method thereof

A technology of ultra-high pressure and multi-grain rice, which is applied in the agricultural field, can solve the problems of single nutrition and taste, and achieve the effect of good taste, uniform water distribution and complete grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

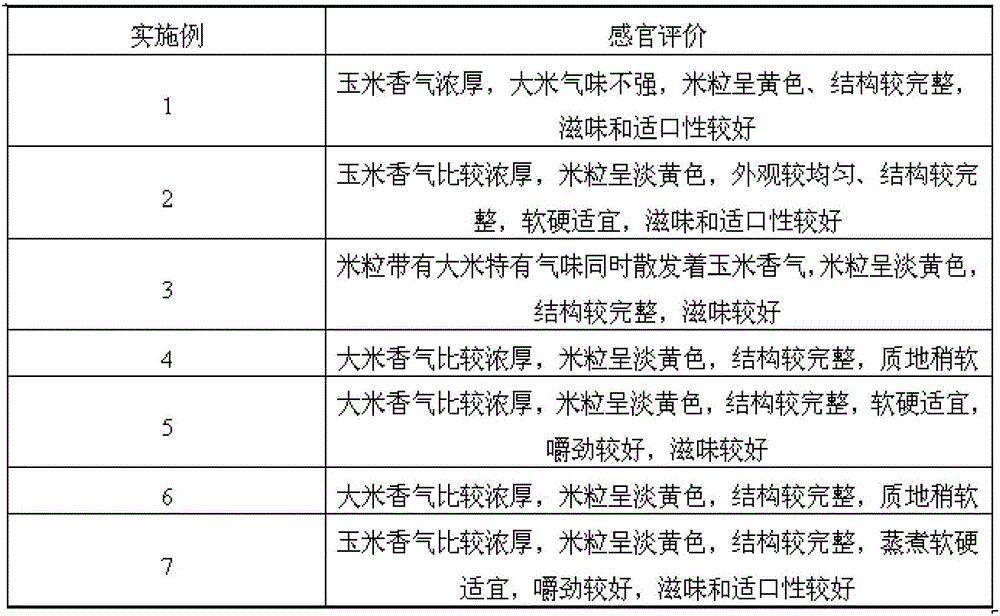

Examples

Embodiment 1

[0042] Ultra-high pressure artificial miscellaneous grain rice is prepared from the following raw materials:

[0043] 350g rice;

[0044] 400g corn;

[0045] Soy protein isolate powder 150g;

[0046] Sweet potato starch phosphate 100g.

[0047] Its preparation method comprises the following steps:

[0048] (1) Raw material pulverization: put rice and corn into pulverizer respectively to pulverize, separate through 60 mesh screens, obtain rice flour and corn flour respectively;

[0049] (2) Mixing: get 350g rice flour, 400g corn flour, 150g soybean protein isolate powder and 100g sweet potato starch phosphate and mix evenly, add 220g water and knead into dough;

[0050] (3) Vacuum sealing: put the dough into a double-layer vacuum packaging bag, and vacuum seal;

[0051] (4) Ultra-high pressure treatment: put the vacuum-sealed dough into a high-pressure container equipped with deionized water, and treat it under a pressure of 200MPa for 28min, and the speed of pressure rise...

Embodiment 2

[0059] Ultra-high pressure artificial miscellaneous grain rice is prepared from the following raw materials:

[0060] 300g rice;

[0061] 400g corn;

[0062] Soy protein isolate powder 150g;

[0063] Sweet potato starch phosphate 150g.

[0064] Its preparation method comprises the following steps:

[0065] (1) Raw material pulverization: put rice and corn into pulverizer respectively to pulverize, separate through 60 mesh screens, obtain rice flour and corn flour respectively;

[0066] (2) Mixing: get 350g rice flour, 400g corn flour, 150g soybean protein isolate powder and 150g sweet potato starch phosphate and mix evenly, add 220g water and knead into dough;

[0067] (3) Vacuum sealing: put the dough into a double-layer vacuum packaging bag, and vacuum seal;

[0068] (4) Ultra-high pressure treatment: put the vacuum-sealed dough into a high-pressure container equipped with deionized water, and process it under a pressure of 100 MPa for 30 minutes, and the speed of pressur...

Embodiment 3

[0076] Ultra-high pressure artificial miscellaneous grain rice is prepared from the following raw materials:

[0077] 400g rice;

[0078] 400g corn;

[0079] Soy protein isolate powder 100g;

[0080] Sweet potato starch phosphate 100g.

[0081] Its preparation method comprises the following steps:

[0082] (1) Raw material pulverization: put rice and corn into pulverizer respectively to pulverize, separate through 60 mesh screens, obtain rice flour and corn flour respectively;

[0083] (2) Mixing: get 400g rice flour, mix with 400g corn flour, 100g soybean protein isolate powder and 100g sweet potato starch phosphate, add 220g water and knead into dough;

[0084] (3) Vacuum sealing: put the dough into a double-layer vacuum packaging bag, and vacuum seal;

[0085] (4) Ultra-high pressure treatment: put the vacuum-sealed dough into a high-pressure container equipped with deionized water, and treat it under a pressure of 600MPa for 5min, and the speed of pressure rise is abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com