Paste honey and processing technique thereof

A processing technology and honey technology, applied in application, food preparation, food science and other directions, can solve the problems of uneven water distribution, low water content in the crystal part, and deterioration of honey taste, so as to achieve bright color, uniform moisture distribution, and avoid deterioration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

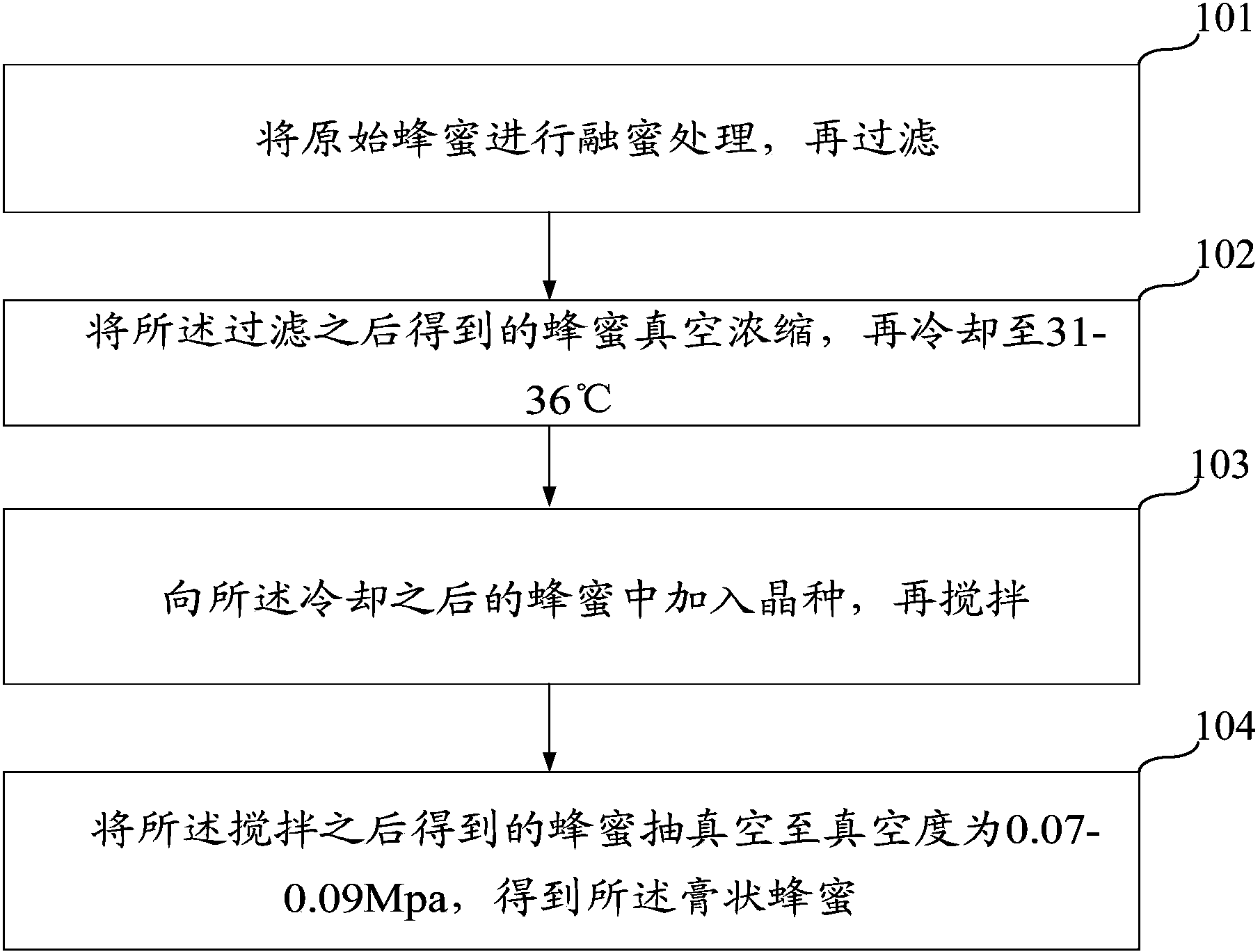

[0014] The processing technology of paste honey, such as figure 1 shown, including the following steps:

[0015] Step 101: Melting raw honey and then filtering;

[0016] Step 102: concentrating the honey obtained after filtration in vacuum, and then cooling to 31-36°C;

[0017] Step 103: Add seed crystals to the cooled honey, and stir again; wherein, the seed crystals are natural crystals of the original honey, the seed crystals have a particle size of 20-40 μm, and the weight ratio of the added seed crystals to the cooled honey is For: 10-15:100;

[0018] Step 104: Vacuumize the honey obtained after stirring to a vacuum degree of 0.07-0.09Mpa to obtain paste honey.

[0019] The temperature, particle size, and weight ratio mentioned in the above steps can be any value within their numerical range, for example, the particle size of the seed crystal can be 20, 30, 40 μm, etc.

[0020] The above processing technology adds a certain proportion of seed crystals, controls the te...

Embodiment 2

[0032] This embodiment provides a paste honey, which is the paste honey prepared by any one of the processing techniques provided above, and has the technical effects of the corresponding processing techniques.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com