Fully automatic production technology of handmade noodles and fermented noodles

A fully automated, production process technology, applied in food science and other directions, can solve the problems of poor elasticity, hard taste of machine-made noodles, affecting sales, etc., and achieve the effect of improving tensile force, uniform moisture distribution, and increasing gluten formation and ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

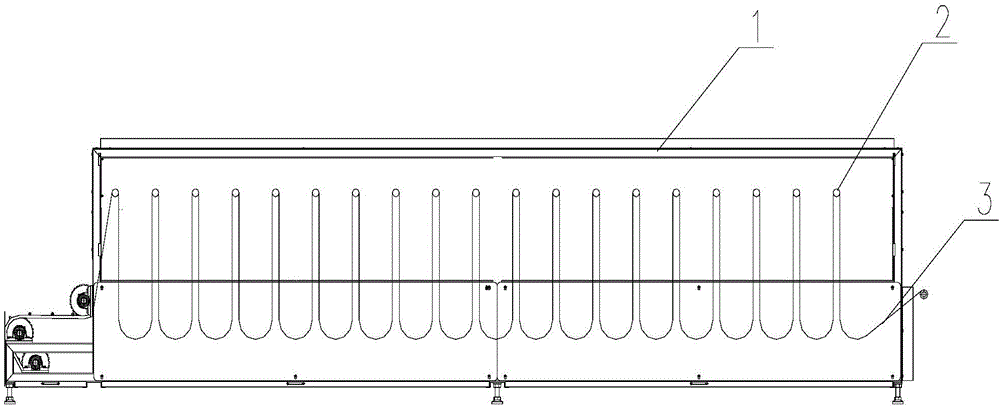

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The present invention proposes a fully automatic production process for manual noodles and fermented noodles, which is prepared according to the following process steps:

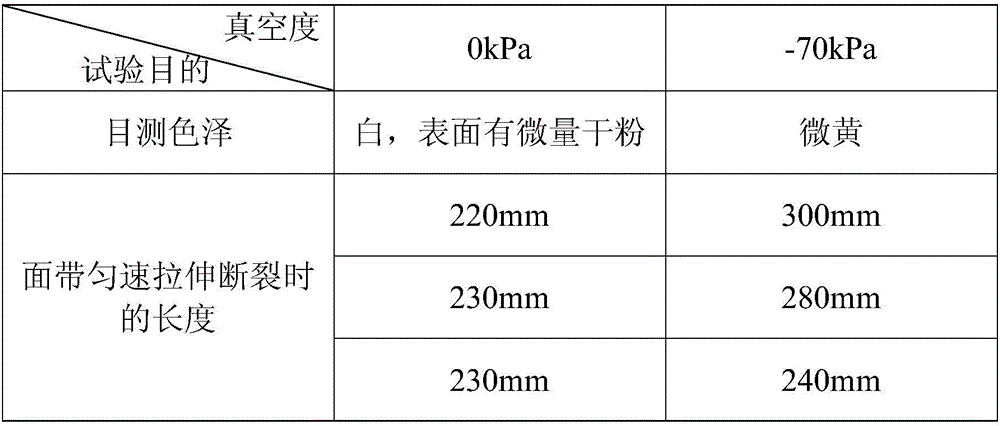

[0024] a) Vacuum kneading: make the noodle box in a vacuum state before kneading, use the stirring shaft to make the flour and water fast and tightly combined, and quickly separate out gluten to form a noodle block, and the vacuum degree is maintained between -75kpa to -90kpa;

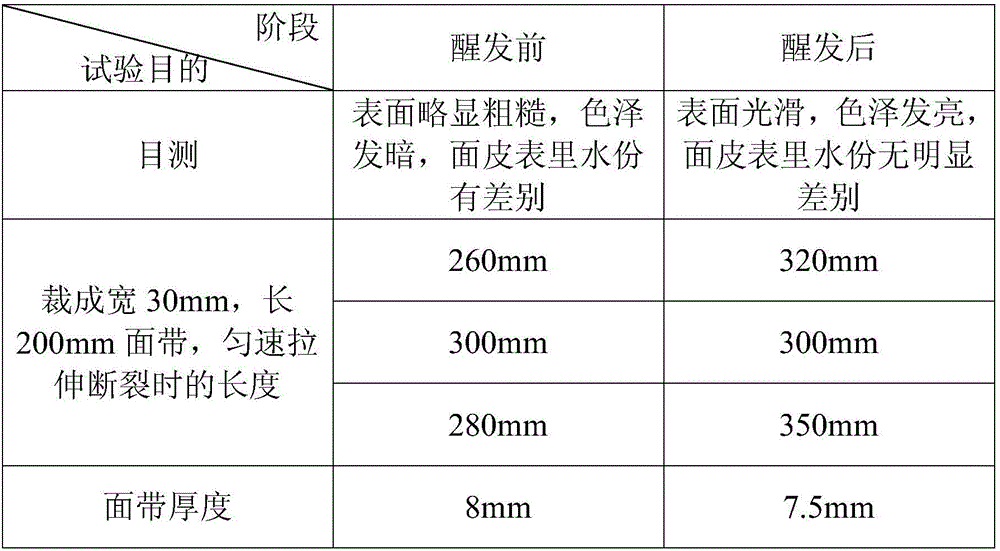

[0025] b) Proofing of dough: the dough that has been reconciled by the dough mixer is initially proofed during the process of slowly advancing on the conveyor belt, and is continuously fed to the noodle press for 8-12 minutes;

[0026] c) Noodle strip forming: Two opposite rollers pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com