Preparation method for nattokinase lyophilized powder

A technology of nattokinase and freeze-dried powder is applied in the field of preparation of nattokinase freeze-dried powder, can solve the problems of poor drying effect, difficult to store for a long time, low enzyme activity, etc., and achieves high purity and enzyme activity, high enzyme activity , the effect of increasing the content of nattokinase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

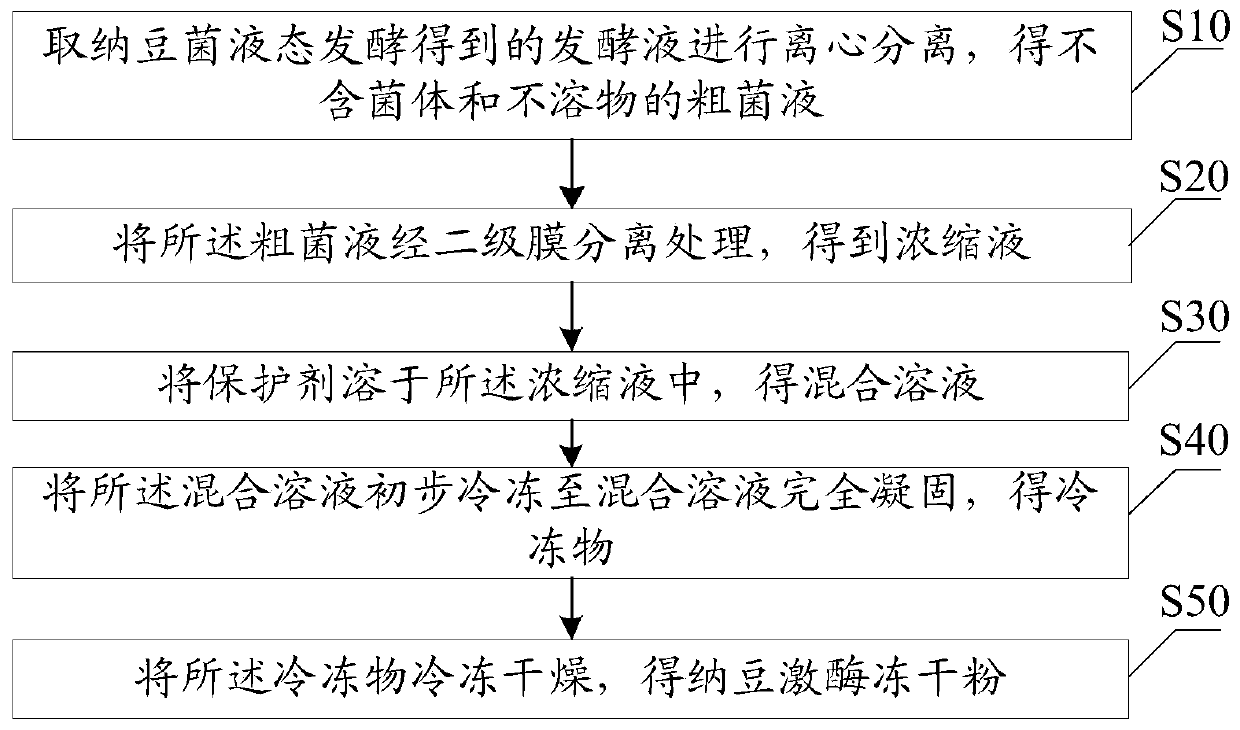

[0034] In order to solve the above problems, prepare high activity, long shelf-life nattokinase freeze-dried powder, the present invention proposes a kind of preparation method of nattokinase freeze-dried powder, combine figure 1 The schematic flow sheet of an embodiment of the preparation method of the provided nattokinase freeze-dried powder, as can be known, the preparation method of described nattokinase freeze-dried powder comprises the following steps:

[0035] Step S10, taking the fermented liquid obtained from the liquid state fermentation of Bacillus natto and performing centrifugation to obtain a crude bacterial liquid free of bacterial cells and insoluble matter.

[0036] Nattokinase is a kind of protease produced by Bacillus subtilis natto. At present, it is generally prepared by solid fermentation. Since the fermentation product contains many bacteria and insoluble impurities, it is necessary to separate impurities from it to improve its content. Therefore, in thi...

Embodiment 1

[0060] The fermented liquid obtained from the liquid state fermentation of Bacillus natto was centrifuged at 8000 r / min for 20 minutes to obtain a crude bacterial liquid free of bacterial cells and insoluble matter. Pass the crude bacterial solution through the ultrafiltrate with a molecular weight cut-off of 50KDa to obtain the permeate; then pass the permeate through the ultrafiltration membrane with a molecular weight cut-off of 10KDa to collect the concentrate. Take the concentrated solution, add 10% (w / v) protective agent therein, stir and mix to obtain a mixed solution, wherein the protective agent is glucose. The mixed solution was initially frozen at -80°C for 8 hours, so that the mixed solution was completely solidified to form a frozen product. Then put the frozen material into a freeze-drying device, and freeze-dry at -40° C. for 24 hours to obtain a freeze-dried nattokinase powder.

[0061] The water content of the above-mentioned nattokinase freeze-dried powder m...

Embodiment 2

[0064] The fermented liquid obtained from liquid state fermentation of Bacillus natto was centrifuged at 12,000 r / min for 10 minutes to obtain a crude bacterial liquid free of bacterial cells and insoluble matter. Pass the crude bacterial solution through the ultrafiltrate with a molecular weight cut-off of 45KDa to obtain the permeate; then pass the permeate through the ultrafiltration membrane with a molecular weight cut-off of 15KDa to collect the concentrate. Take the concentrate, add 4% (w / v) protective agent therein, stir and mix to obtain a mixed solution, wherein the protective agent is xylitol. The mixed solution was initially frozen at -75°C for 16 hours, so that the mixed solution was completely solidified to form a frozen product. Then put the frozen material into a freeze-drying device, and freeze-dry at -60° C. for 72 hours to obtain a freeze-dried nattokinase powder.

[0065] The water content of the above-mentioned nattokinase freeze-dried powder measured by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com