Processing method of vegetable protein meat bionic fibers

A technology of vegetable protein meat and processing method, applied in the field of new food processing, can solve problems such as invaluable technical parameters, and achieve the effects of improving spinning efficiency, strong applicability and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A processing method of plant protein meat biomimetic fiber is processed by using a plant protein meat biomimetic fiber processing device.

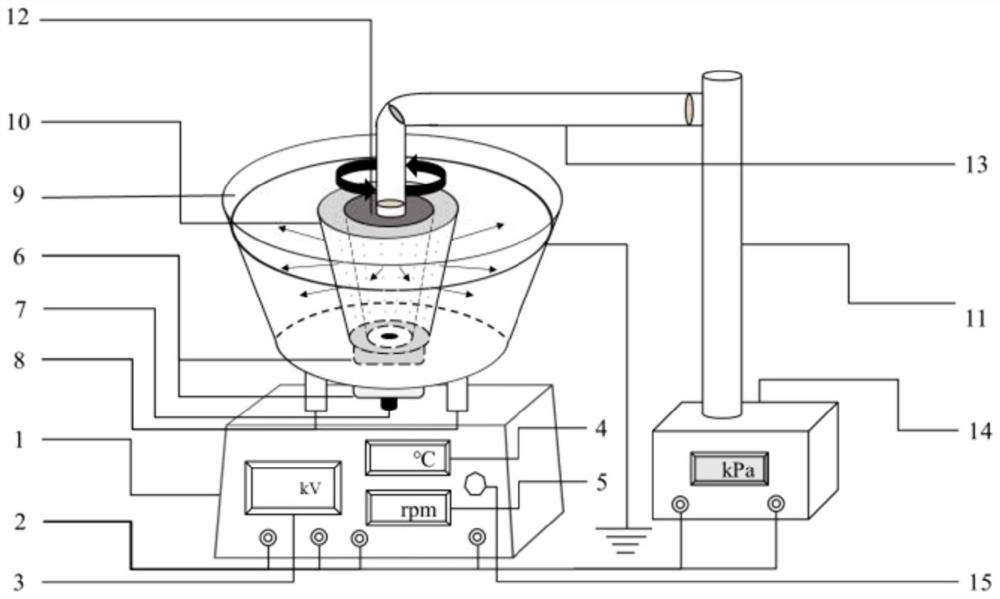

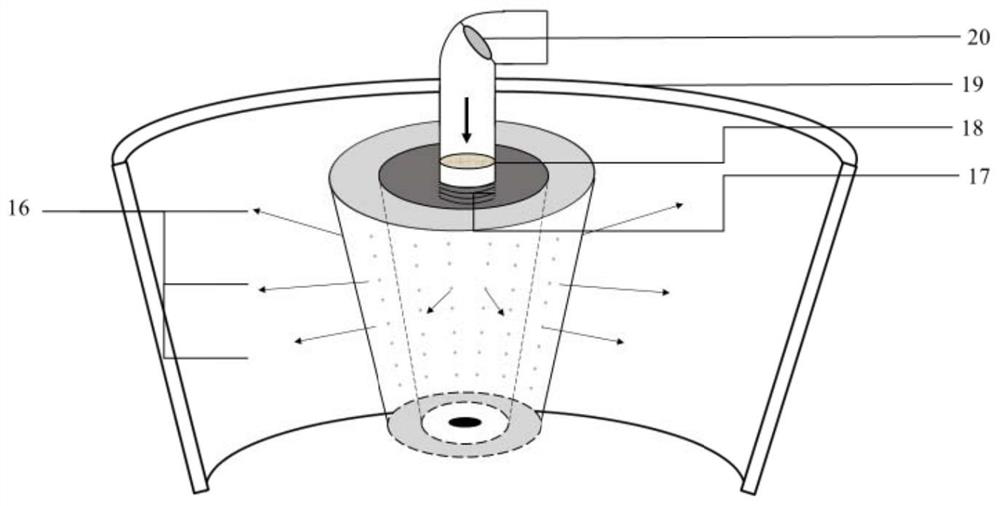

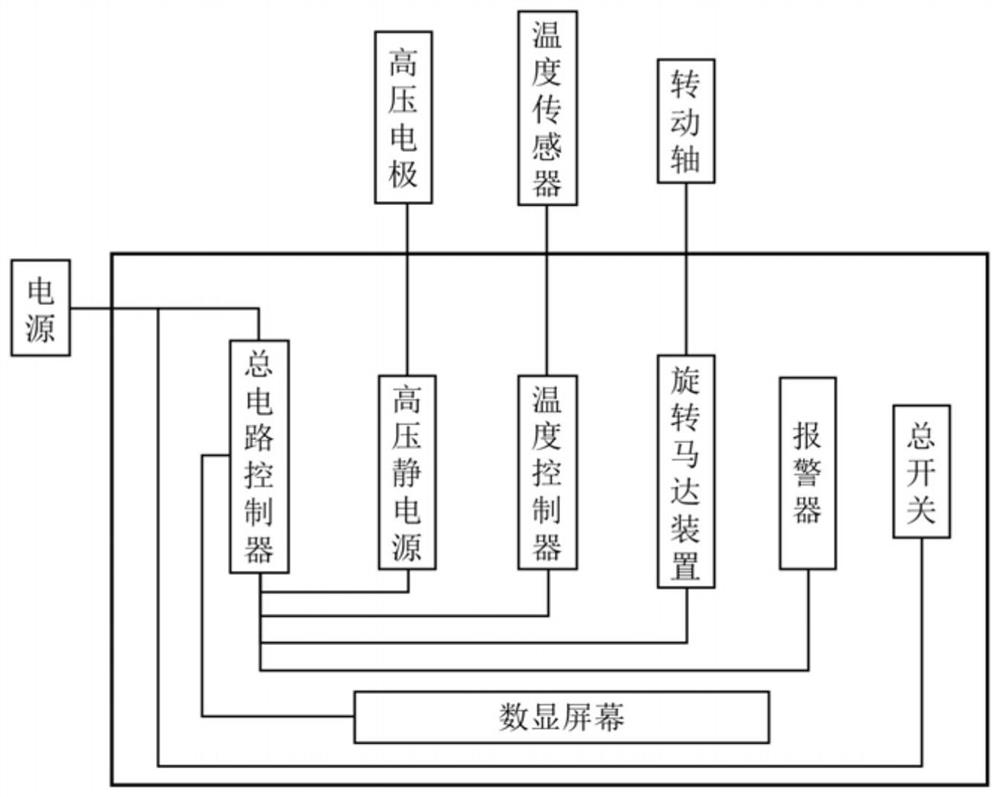

[0039] like figure 1 and figure 2 As shown, the processing device includes: a needle-free fiber generator 10, a fiber receiver 9 surrounding the outside of the needle-free fiber generator 10, a console 1 below the fiber receiver 9, and one end connected to the needle-free fiber generator 10 The air filter pipe 13 and the compressed air pump 14 connected with the other end of the air filter pipe 13; the needle-free fiber generator 10 is a truncated circular drum, the drum wall is evenly distributed with spinneret holes, and the interlayer of the drum wall is provided with temperature sensor, the inside of the drum is provided with a hollow cavity as the spinning solution storage chamber 12; the area of the upper bottom of the frustum-shaped drum is larger than the area of the lower bottom, and the upper bottom is provided with ...

Embodiment 2

[0060] This embodiment generates vegetable protein chicken bionic fiber material (such as Figure 4 ), the processing device adopted is the same as that of Example 1, and the specific operating parameters are: the spinning liquid composition is: soybean protein, edible alcohol, purified water, sunflower oil, chicken essence, emulsification stabilizer, natural pigment; The diameter of the spinneret hole on the wall is 80 μm, and the aperture coverage rate is 40%; the high voltage electrostatic value is 24 kv; the heating temperature is 32 ° C; the rotational speed of the rotating motor is 350 rpm.

Embodiment 3

[0062] In this example, the plant protein pork bionic fiber material is produced, and the processing device adopted is the same as in Example 1, and the specific operating parameters are: the spinning solution components are: soybean protein, edible alcohol, purified water, sunflower oil, pork essence, Emulsion stabilizer, natural pigment; spinneret hole size of drum wall: 140 μm, hole coverage rate: 40%; high voltage electrostatic value: 18 kv; heating temperature: 36 ℃; rotating motor speed: 260 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com