Shiitake mushroom powder extruding, puffing and processing method and processing equipment

A technology of extrusion puffing and processing equipment, which is applied in the field of puffing processing and shiitake powder extrusion and puffing processing, can solve the problems of complicated procedures, difficulty in realizing industrialized production, and undisclosed processing and production equipment, etc., and achieves the effect of fine taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

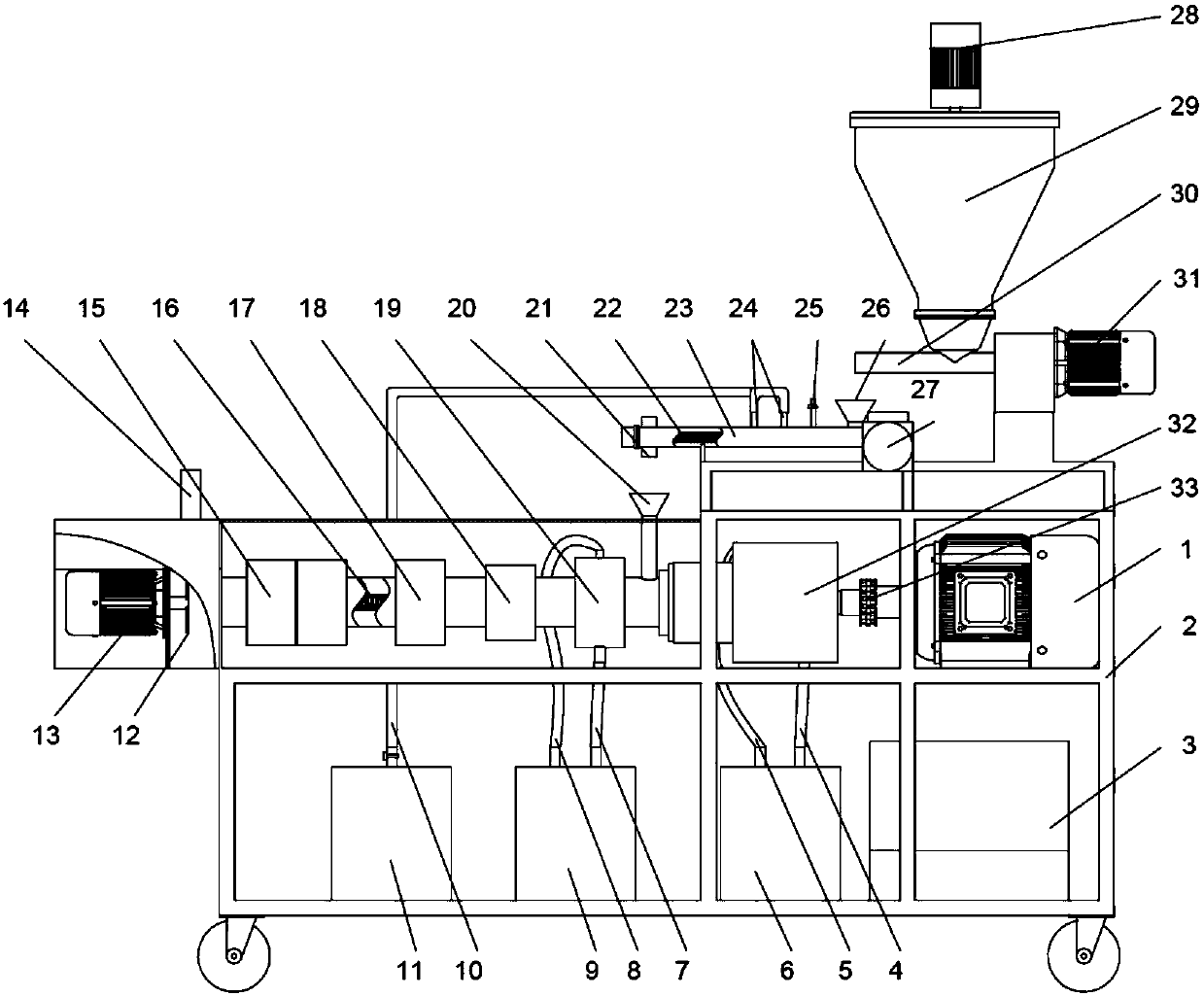

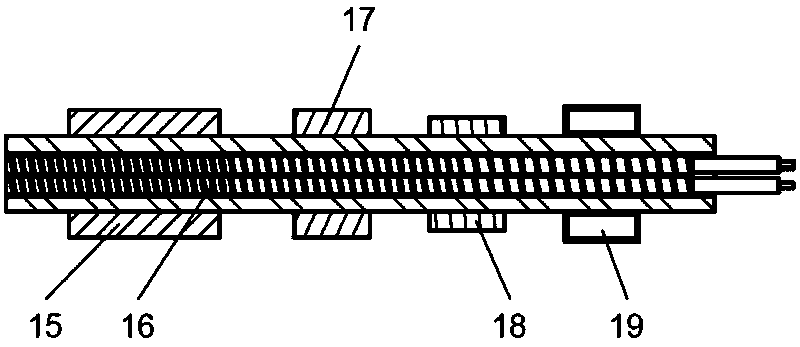

[0021] The shiitake mushroom powder extrusion processing equipment of this embodiment is as follows figure 1 As shown, a steam generator 11, a cooling water tank 9 and a lubricating oil tank 6 are arranged at the bottom of the rack 2 with rollers. A funnel-shaped stirring device 29 is installed above the frame 2, in which a stirring paddle driven by a stirring motor 28 is installed. The dropping end of the stirring device 29 is equipped with a horizontal screw feeding device 30 driven by a feeding motor 31, and below the outlet of the feeding device 30 is an inlet 26 of the opposite conditioning device 23.

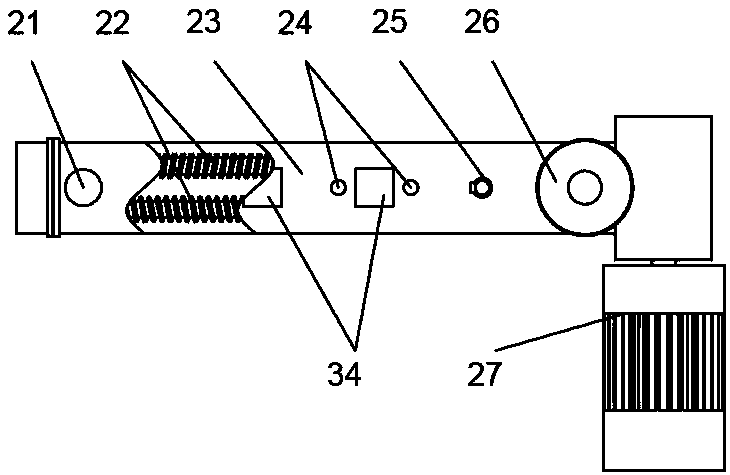

[0022] Conditioning device 23 such as figure 2 As shown, there are two parallel and oppositely rotating horizontal quenching and tempering augers 22, which are driven by a quenching and tempering motor 27 through a transmission mechanism. The middle of the conditioning device 23 is fed with steam from the steam generator 11 through two steam inlets 24. The two oppositely rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com