Expanding and high heat dissipation material and preparing method thereof

A heat-dissipating material and high heat-dissipating technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

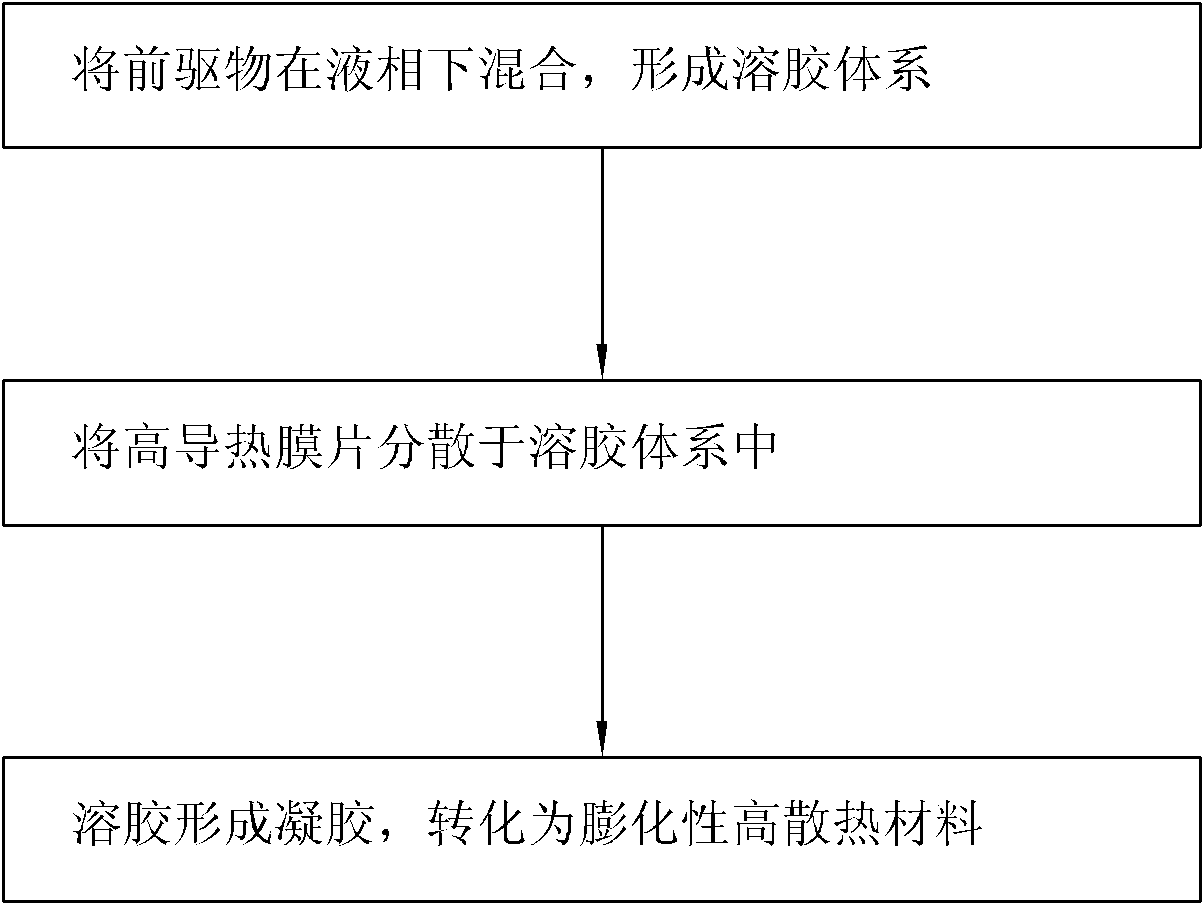

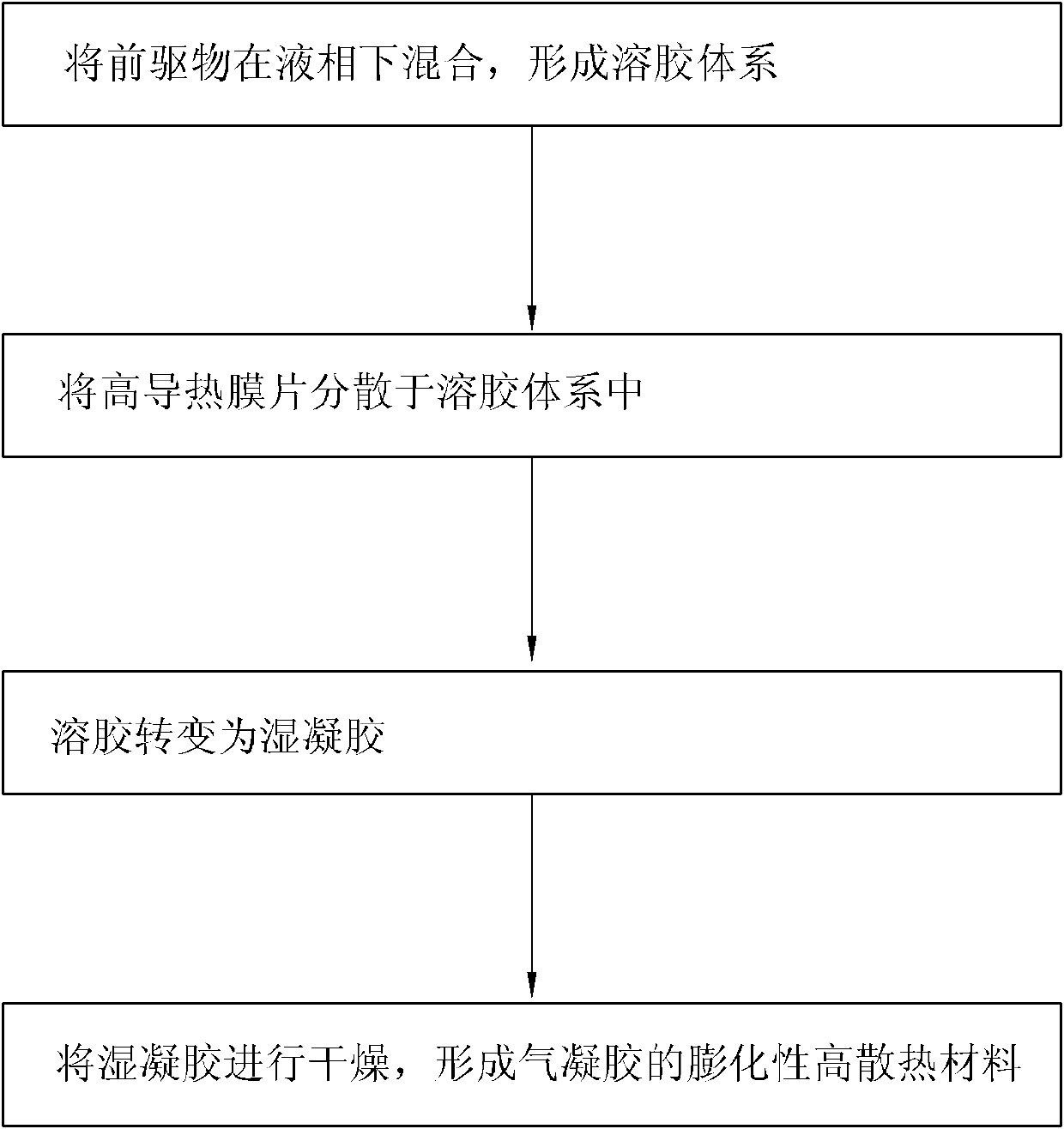

Method used

Image

Examples

Embodiment Construction

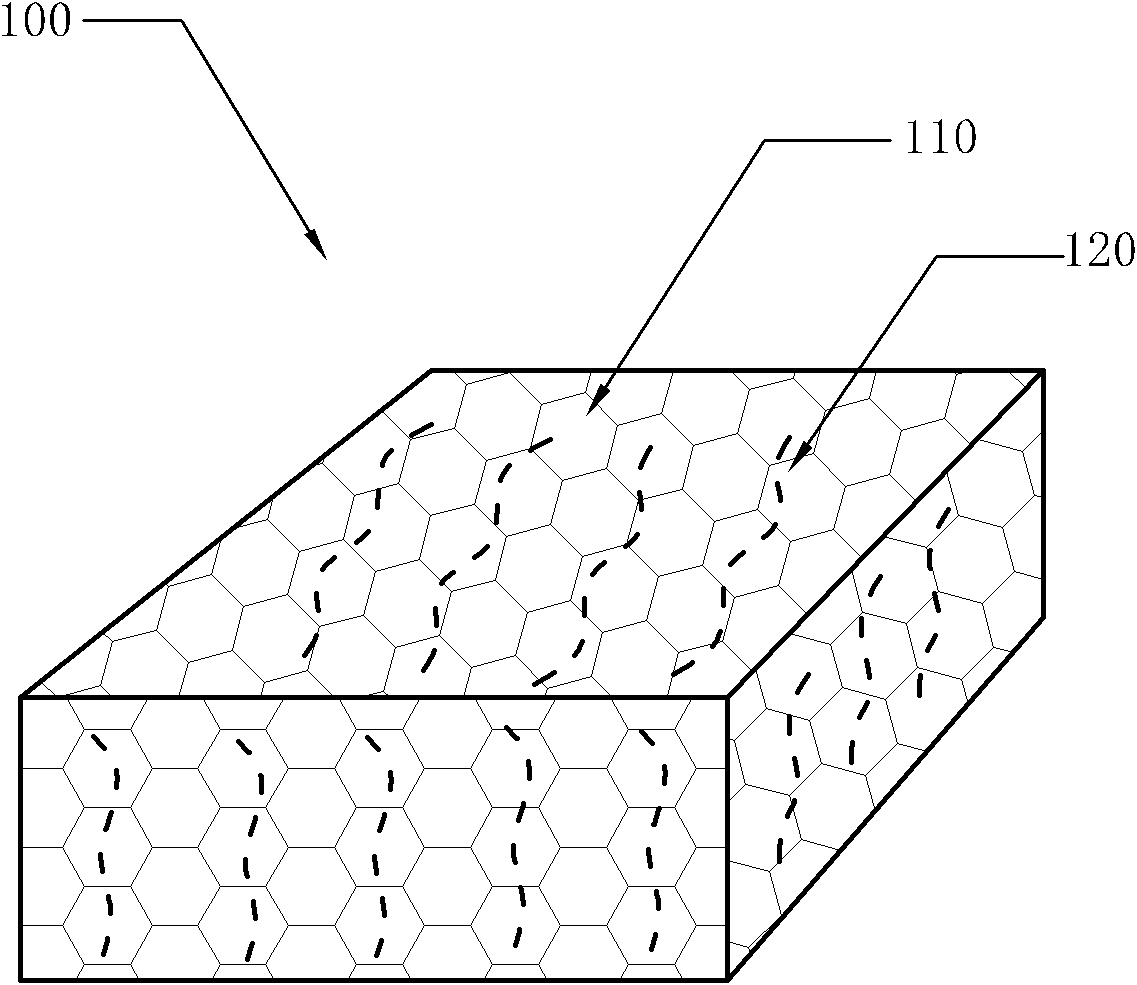

[0032] In the present invention, an expandable high heat dissipation material and its corresponding preparation method are provided. Combine below figure 1 As shown, first, the prepared product expansion high heat dissipation material is described in detail.

[0033] Such as figure 1 Shown is a schematic diagram of an expandable high heat dissipation material. The expandable high heat dissipation material 100 is composed of a gel 110 and a high heat dissipation film 120 dispersed in the gel.

[0034] The gel 110 refers to that the colloidal particles or macromolecules in the sol or solution are connected to each other under certain conditions to form a spatial network structure. When the dispersion medium filled in the structural voids is a liquid, it is a liquid gel, and the structural voids When the dispersion medium filled in the medium is gas, it is an aerogel, and if the organic aerogel is further carbonized, it will form a carbon aerogel. The gel 110 described in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com