Large-span triangular truss aerial rotation lifting construction method

A technology of triangular truss and construction method, which is applied in the directions of instruments, transportation and packaging, analysis of materials, etc., can solve the problems of insufficient space for truss hoisting space and truss hoisting space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

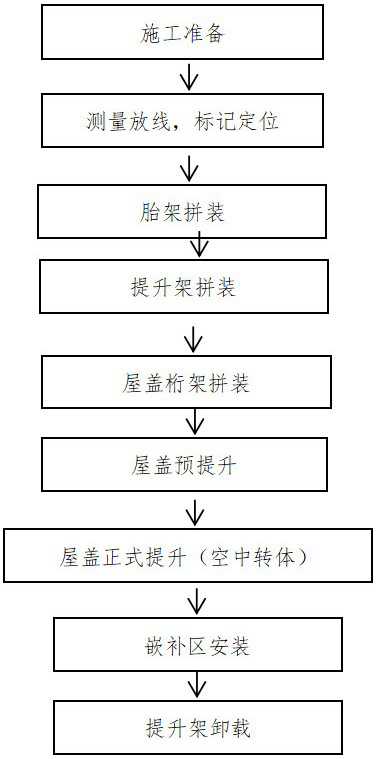

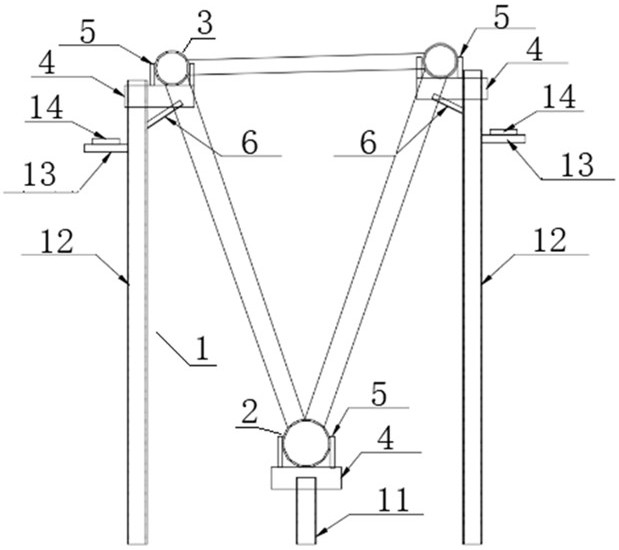

[0040] Such as Figure 1-Figure 2 As shown, a large-span triangular truss aerial swivel lifting construction method specifically includes the following steps:

[0041] S1: Construction preparation: model according to the construction drawing, and split and number the steel beams, truss tubes and related components in the model, and process the finished components according to the model;

[0042] S2: Surveying and setting out: establish a site surface control network, which includes the starting point and starting edge as the basis for site positioning, the main point and main axis of the building, and related control lines and control points, so as to form a surrounding parallel to the building the closed figure of

[0043] S3: tire frame assembly: build the roof truss assembly tire frame 1, and set them on the embedded parts of the concrete structure of the elevated floor and on the ground respectively;

[0044] S4: Lifting frame assembly and roof truss lifting: Build the l...

Embodiment 2

[0069] Process flow is as follows in the present embodiment:

[0070] Construction preparation→measurement and setting out, marking and positioning→tire frame assembly→lifting frame assembly→roof truss assembly→

[0071] Pre-lifting of the roof → formal lifting of the roof (air swivel) → unloading of the lifting frame;

[0072] Specific steps are as follows:

[0073] 1. Construction preparation

[0074] According to the design drawings, BIM software is used to model the steel structure of the station building. According to the model, steel beams, truss tubes and other components are accurately split and numbered. The materials are cut according to the project construction schedule, and the factory is customized according to the specified specifications and models, and then enters the site to prepare for inspection and installation. After the components enter the site, check the external dimensions, welding quality and coating quality of the components according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com