Super-hydrophobic fabric and preparation method thereof

A super-hydrophobic, fabric technology, applied in the field of super-hydrophobicity, can solve the problem that it can only be used on a specific type of fabric surface, and achieve the effect of maintaining the super-hydrophobic effect for a long time, mild conditions and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

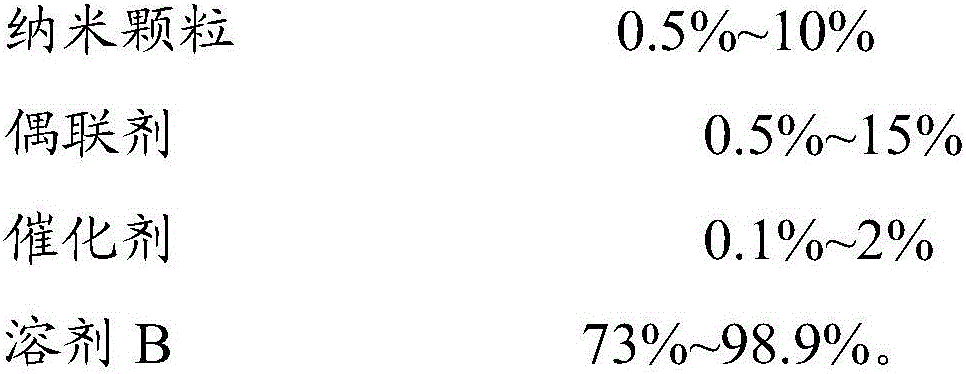

Method used

Image

Examples

Embodiment 1

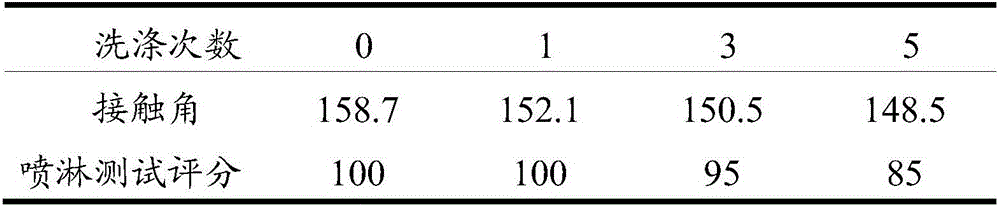

[0047] Clean the cotton fabric, rinse and dry it, soak it in the ethanol solution of 5g / L γ-aminopropyltrimethoxysilane for 2min, and dry it at 80℃ for later use; Into 93g of ethanol, ultrasonically oscillate for 15min, stir at 60°C for 2h, add 4g of octadecyltrimethoxysiloxane, continue stirring, slowly add 2mL of ammonia water, and stir for 20h. Add the treated cotton fabric to this solution, soak for 30 minutes, dry at 80°C, and bake at 170°C for 1 minute to obtain a superhydrophobic cotton fabric, measure its static contact angle and spray test score, and simultaneously carry out washing experiments and measure , and the measurement results are shown in Table 1.

[0048] Table 1. Fabric static contact angle and spray test score under various washing times

[0049]

[0050] Through the preparation method of this example, hemp fabrics, wool fabrics, polyester fabrics, blended fabrics, etc. are subjected to superhydrophobic treatment, and the superhydrophobic properties a...

Embodiment 2

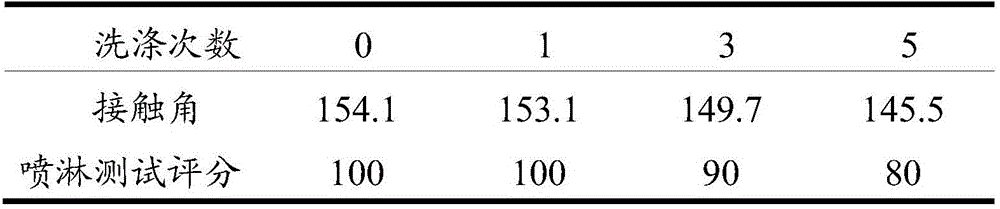

[0052] Clean the nylon fabric, rinse and dry it, soak it in the acetone solution of 3g / L γ-glycidyl etheroxypropyltrimethoxysilane for 20min, and dry it at 80°C for later use; Add silicon oxide into 90g of acetone, oscillate ultrasonically for 20min, stir at 50°C for 2h, add 6g of hexadecyltriethoxysiloxane, continue stirring, slowly add 2mL of ammonia water, and stir for 20h. Add the treated nylon fabric to this solution, soak it for 30 minutes, dry it in the air, and bake it at 150°C for 5 minutes to obtain a durable superhydrophobic nylon fabric. Measure its static contact angle and spray test score. At the same time, perform a washing experiment and measure it. The results are shown in Table 2.

[0053] Table 2. Fabric static contact angle and spray test score under various washing times

[0054]

[0055] Superhydrophobic treatment of cotton fabrics, polyester fabrics, wool fabrics, blended fabrics, etc. by the preparation method of this example, the superhydrophobic p...

Embodiment 3

[0057] Clean the polyester fiber fabric, rinse and dry it, soak it in the toluene solution of 3g / L γ-aminopropylmethyldimethoxysilane for 15min, and dry it at 80°C for later use; Add nano-sized titanium dioxide into 75g of acetone, oscillate ultrasonically for 30min, stir at 50°C for 2h, add 15g of octadecyltriethoxysiloxane, continue stirring, slowly add 0.5g of sodium carbonate, and stir for 20h. Add the treated polyester fiber to this solution, soak for 30min, dry at 80°C, and bake at 180°C for 30s to obtain a durable superhydrophobic polyester fabric, measure its static contact angle and spray test score, and wash at the same time Experiment and measure, and the measurement results are shown in Table 3.

[0058] Table 3. Fabric static contact angle and spray test score under various washing times

[0059]

[0060] Through the preparation method of this example, superhydrophobic treatment is carried out on cotton and linen fabrics, nylon fabrics, blended fabrics, etc., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com