Nonwoven composite material with oriented water guide function, and manufacturing method thereof

A composite material and non-woven technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of heavy fabrics, affecting human health, and failure to realize directional water conduction at the same time, and achieve strong adaptability and directional water guide effect excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

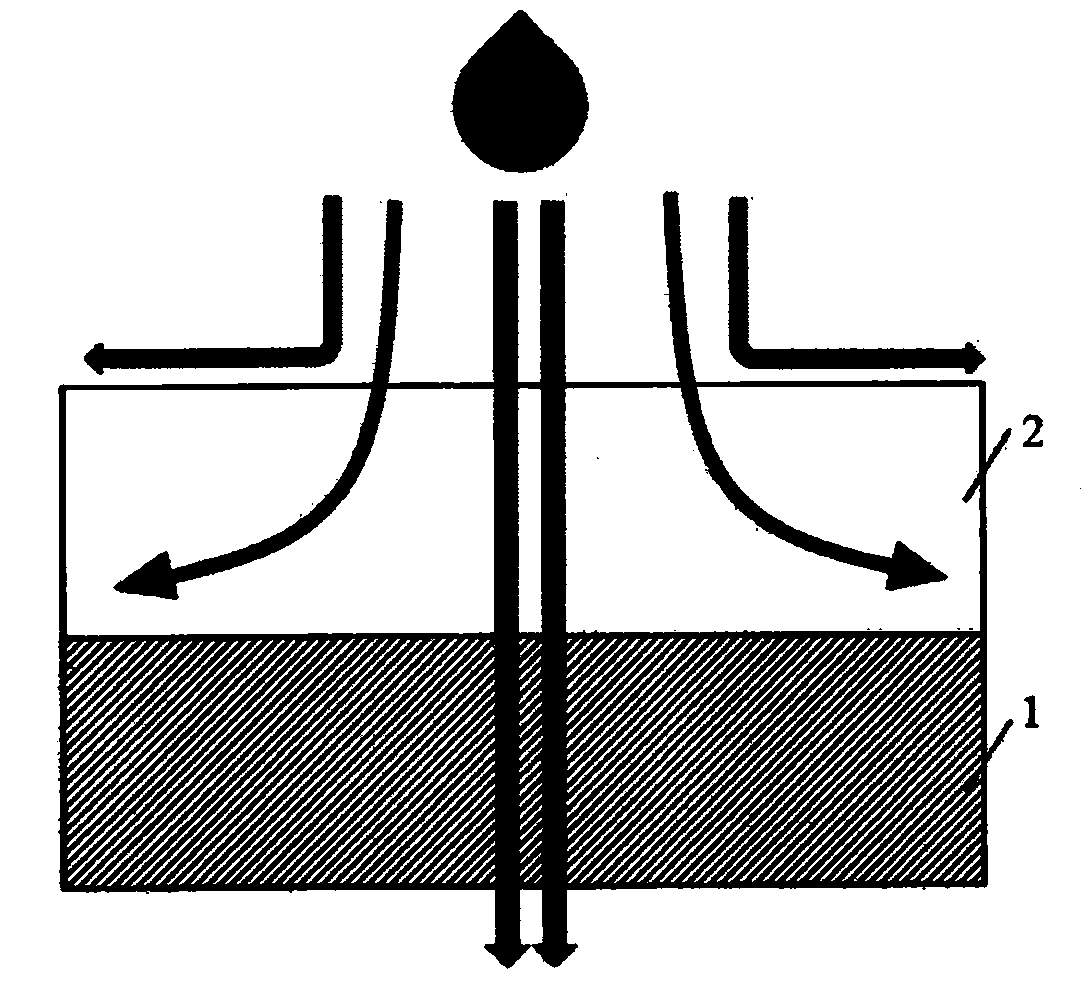

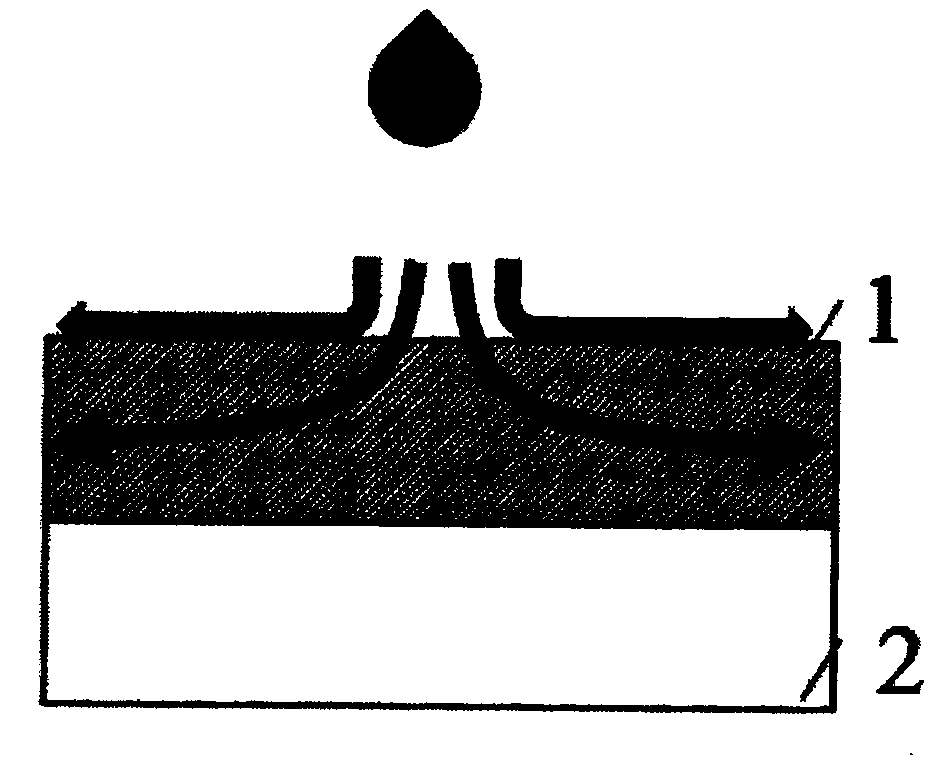

[0047] like figure 1 As shown, the non-woven composite material with directional water-conducting function in this embodiment is composed of a hydrophilic layer 3, a water-repellent layer 5, and a mixed layer 4 located between the hydrophilic layer 3 and the water-repellent layer 5. The hydrophilic layer 3 is composed of hydrophilic fibers 1, the water-repellent layer 5 is composed of hydrophobic fibers 2, and the mixed layer 4 is composed of hydrophilic fibers 1 and hydrophobic fibers 2, wherein the Most of the hydrophilic fibers 1 in the hydrophilic layer 3 and most of the hydrophobic fibers 2 in the water-repellent layer 5 are arranged in a certain direction, and the arrangement direction of the two is the same, which is the horizontal direction. Part of the hydrophilic fibers 1 and part of the hydrophobic fibers 2 in the mixed layer 4 are arranged along the thickness direction (vertical direction) of the mixed layer 4 .

[0048] The preparation method of the above-mention...

Embodiment 2

[0058] like figure 1 As shown, the non-woven composite material with directional water-conducting function in this embodiment is composed of a hydrophilic layer 3, a water-repellent layer 5, and a mixed layer 4 located between the hydrophilic layer 3 and the water-repellent layer 5. The hydrophilic layer 3 is composed of hydrophilic fibers 1, the water-repellent layer 5 is composed of hydrophobic fibers 2, and the mixed layer 4 is composed of hydrophilic fibers 1 and hydrophobic fibers 2, wherein the Most of the hydrophilic fibers 1 in the hydrophilic layer 3 and most of the hydrophobic fibers 2 in the water-repellent layer 5 are arranged in a certain direction, and the arrangement direction of the two is the same, which is the horizontal direction. Part of the hydrophilic fibers 1 and part of the hydrophobic fibers 2 in the mixed layer 4 are arranged along the thickness direction (vertical direction) of the mixed layer 4 .

[0059] The preparation method of the above-mention...

Embodiment 3

[0066] like figure 1As shown, the non-woven composite material with directional water-conducting function in this embodiment is composed of a hydrophilic layer 3, a water-repellent layer 5, and a mixed layer 4 located between the hydrophilic layer 3 and the water-repellent layer 5. The hydrophilic layer 3 is composed of hydrophilic fibers 1, the water-repellent layer 5 is composed of hydrophobic fibers 2, and the mixed layer 4 is composed of hydrophilic fibers 1 and hydrophobic fibers 2, wherein the Most of the hydrophilic fibers 1 in the hydrophilic layer 3 and most of the hydrophobic fibers 2 in the water-repellent layer 5 are arranged in a certain direction, and the arrangement direction of the two is the same, which is the horizontal direction. Part of the hydrophilic fibers 1 and part of the hydrophobic fibers 2 in the mixed layer 4 are arranged along the thickness direction (vertical direction) of the mixed layer 4 .

[0067] The preparation method of the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com