Face mask

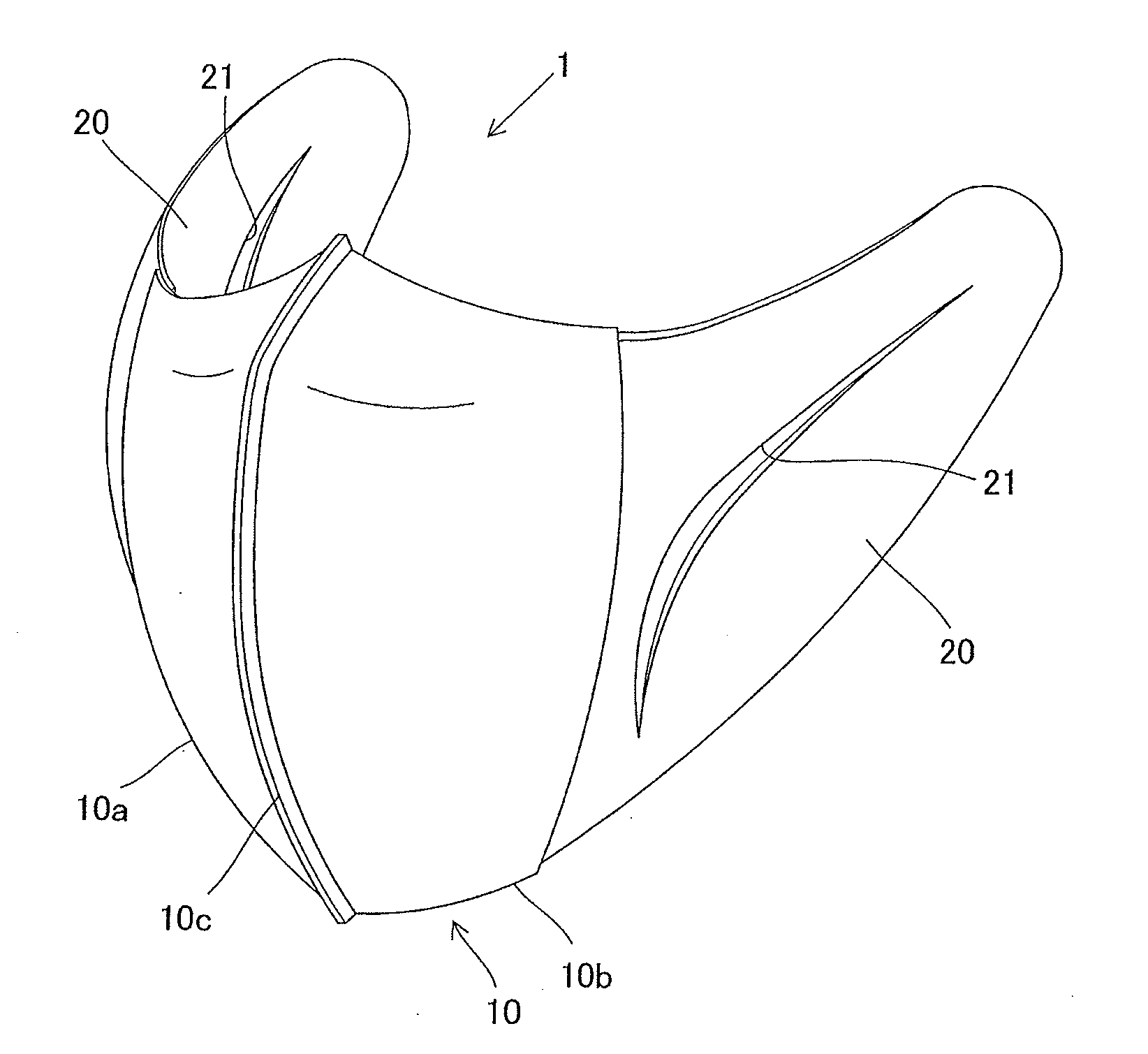

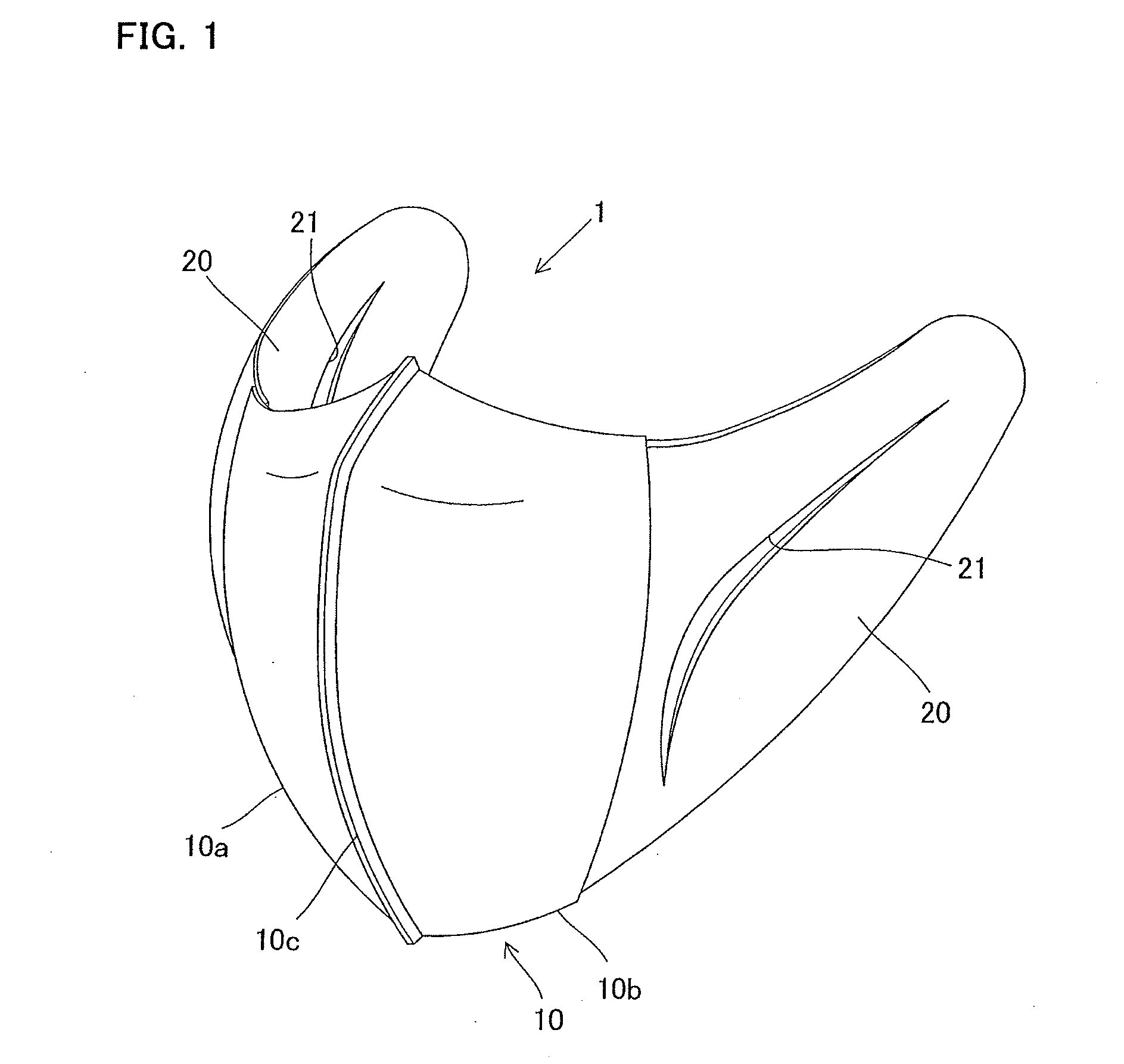

a mask and face technology, applied in the field of mask construction, can solve the problems of insufficient antibacterial and antiviral effects of inorganic antimicrobial agents against pathogens such as bacteria and viruses, secondary infection, wearers may touch the mask body, etc., to achieve high antibacterial and antiviral effects, improve air permeability, and capture efficiency and productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

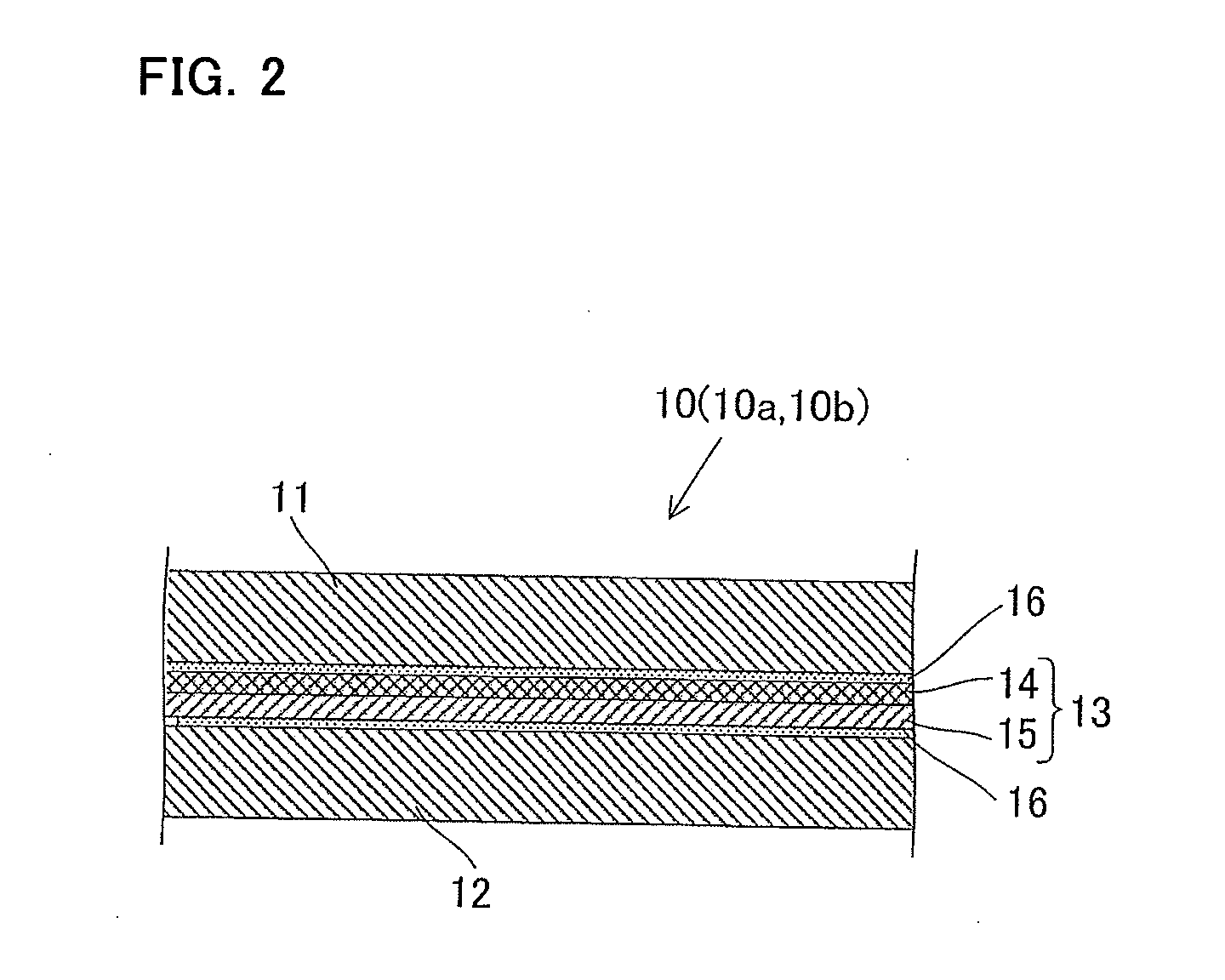

[0058]As for a specimen of example 1, a polypropylene meltblow nonwoven fabric sheet (fiber diameter: 1.5 μm, basis weight: 1.5 g / m2, particle diameter of the inorganic antimicrobial agent: 1.0 μm, particle diameter of the inorganic antimicrobial agent / fiber diameter: 0.7) is used as the nonwoven fabric sheet corresponding to the first fiber layer 14 of the intermediate-layer sheet 13. Further, a polypropylene meltblow nonwoven fabric sheet (fiber diameter: 3.5 μm, basis weight: 15 g / m2) is used as the nonwoven fabric sheet corresponding to the second fiber layer 15 of the intermediate-layer sheet 13. This specimen has the total basis weight of 84.1 g / m2 and contains the inorganic antimicrobial agent of 0.15 g / m2.

example 2

[0059]As for a specimen of example 2, a polypropylene meltblow nonwoven fabric sheet (fiber diameter: 0.5 μm, basis weight: 1.5 g / m2, particle diameter of the inorganic antimicrobial agent: 0.2 μm, particle diameter of the inorganic antimicrobial agent / fiber diameter: 0.4) is used as the nonwoven fabric sheet corresponding to the first fiber layer 14 of the intermediate-layer sheet 13. Further, as the nonwoven fabric sheet corresponding to the second fiber layer 15 of the intermediate-layer sheet 13, the same nonwoven fabric sheet as in the specimen of example 1 is used. This specimen has the same total basis weight and contains the same amount (g / m2) of the inorganic antimicrobial agent as the specimen of example 1.

example 3

[0060]As for a specimen of example 3, a polypropylene meltblow nonwoven fabric sheet (fiber diameter: 1.5μm, basis weight: 1.5 g / m2, particle diameter of the inorganic antimicrobial agent: 0.2 μm, particle diameter of the inorganic antimicrobial agent / fiber diameter: 0.13) is used as the nonwoven fabric sheet corresponding to the first fiber layer 14 of the intermediate-layer sheet 13. Further, as the nonwoven fabric sheet corresponding to the second fiber layer 15 of the intermediate-layer sheet 13, the same nonwoven fabric sheet as in the specimen of example 1 is used. This specimen also has the same total basis weight and contains the same amount of the inorganic antimicrobial agent as the specimen of example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com