Surface modified aramid fiber and preparation method thereof

A technology for surface modification of aramid fiber, applied in the field of surface modification of aramid fiber and its preparation, can solve the problems of unfavorable excellent performance of graphene oxide, coating layer with low content of graphene oxide, inability to obtain anti-ultraviolet performance, etc. , to achieve the effects of highlighting UV resistance, improving surface activity and increasing the coating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Cleaning of aramid fiber

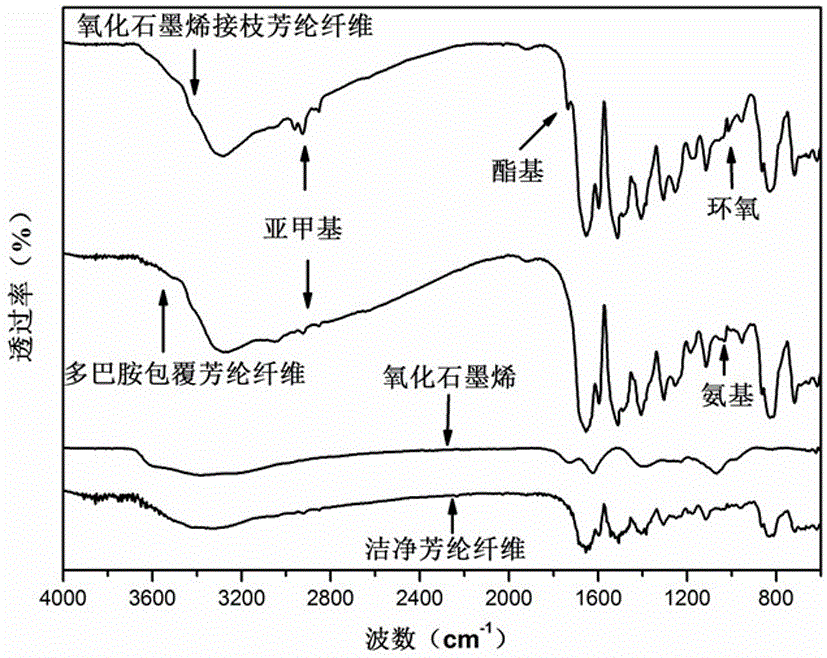

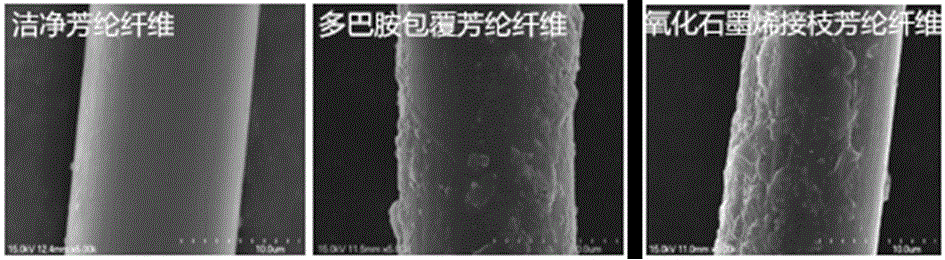

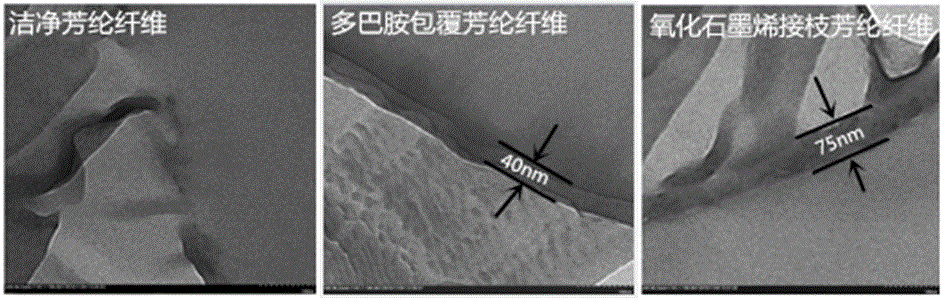

[0028] 5g para-aramid fiber (Kevlar-49, diameter 12μm, density 1.43g / cm 3 , produced by DuPont, USA) were placed in 500mL of acetone, petroleum ether and deionized water in sequence, and refluxed for 3 hours; after cleaning, the fibers were taken out and dried in an oven at 80°C for 6 hours to obtain clean aramid fibers, which were denoted as KF. Its infrared spectrograms, scanning electron microscope photos, and transmission electron microscope photos are shown in the attached figure 1 , 2 , 3, see Table 1 for contact angle and surface activity.

[0029] 2. Preparation of graphite oxide

[0030] At 0°C, mix 5g of graphite, 2.5g of sodium nitrate and 115mL of 98% concentrated sulfuric acid in a flask, and stir for 30 minutes; take 15g of potassium permanganate and slowly add it to the mixture, keep the temperature at 10°C and stir for 2h; Transfer to a 30°C water bath, and keep stirring for 30min. After the reaction, slowly add 230mL o...

Embodiment 2

[0041] 1. Cleaning of aramid fiber

[0042] 5g para-aramid fiber (Kevlar-49, diameter 12μm, density 1.43g / cm 3 , produced by DuPont, USA) were placed in 500mL of acetone, petroleum ether and deionized water in sequence, and refluxed for 3 hours; after cleaning, the fibers were taken out and dried in an oven at 80°C for 6 hours to obtain clean aramid fibers.

[0043] 2. Preparation of dopamine-coated aramid fibers

[0044] First take 5mL of 1M Tris-HCl solution in a 500mL volumetric flask, dilute to the volume, and prepare a 10mM Tris-HCl solution; then prepare a dopamine solution with a concentration of 3g / L, and adjust the pH of the solution to 8.5 with 0.5mol / L sodium hydroxide , to obtain dopamine solution A. Soak 2.5g of the clean aramid fibers obtained in step 1 into dopamine solution A, and shake and react at 25°C for 24h. After the reaction, the fibers were taken out, washed with deionized water, and dried in a vacuum oven at 40° C. for 24 hours. The dopamine-coated...

Embodiment 3

[0048] 1. Cleaning of aramid fiber

[0049] 5g para-aramid fiber (Kevlar-49, diameter 12μm, density 1.43g / cm 3 , produced by DuPont, USA) were placed in 500mL acetone, petroleum ether and deionized water in turn, and refluxed for 3 hours; after cleaning, the fibers were taken out and dried in an oven at 80°C for 6 hours to obtain clean aramid fibers.

[0050] 2. Preparation of dopamine-coated aramid fibers

[0051] First take 5mL of 1M Tris-HCl solution in a 500mL volumetric flask, dilute to the volume, and prepare a 10mM Tris-HCl solution; then prepare a dopamine solution with a concentration of 4g / L, and adjust the pH of the solution to 8.5 with 0.5mol / L sodium hydroxide , to obtain dopamine solution A. Soak 2.5g of the clean aramid fibers obtained in step 1 into dopamine solution A, and shake and react at 25°C for 24h. After the reaction, the fibers were taken out, washed with deionized water, and dried in a vacuum oven at 40° C. for 24 hours. The dopamine-coated aramid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com