Ultraviolet ray emitting element package

A technology for light-emitting elements and ultraviolet rays, which is applied in electrical components, electric solid-state devices, semiconductor devices, etc., and can solve the problems of small degree of deterioration and large refractive index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

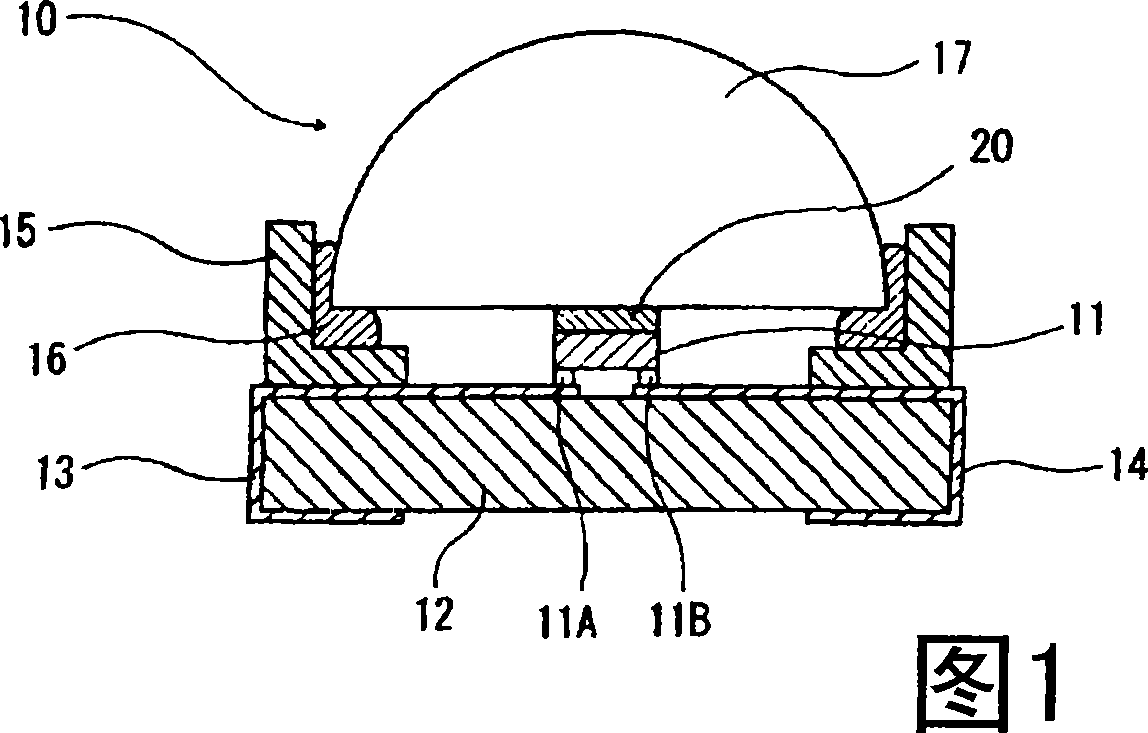

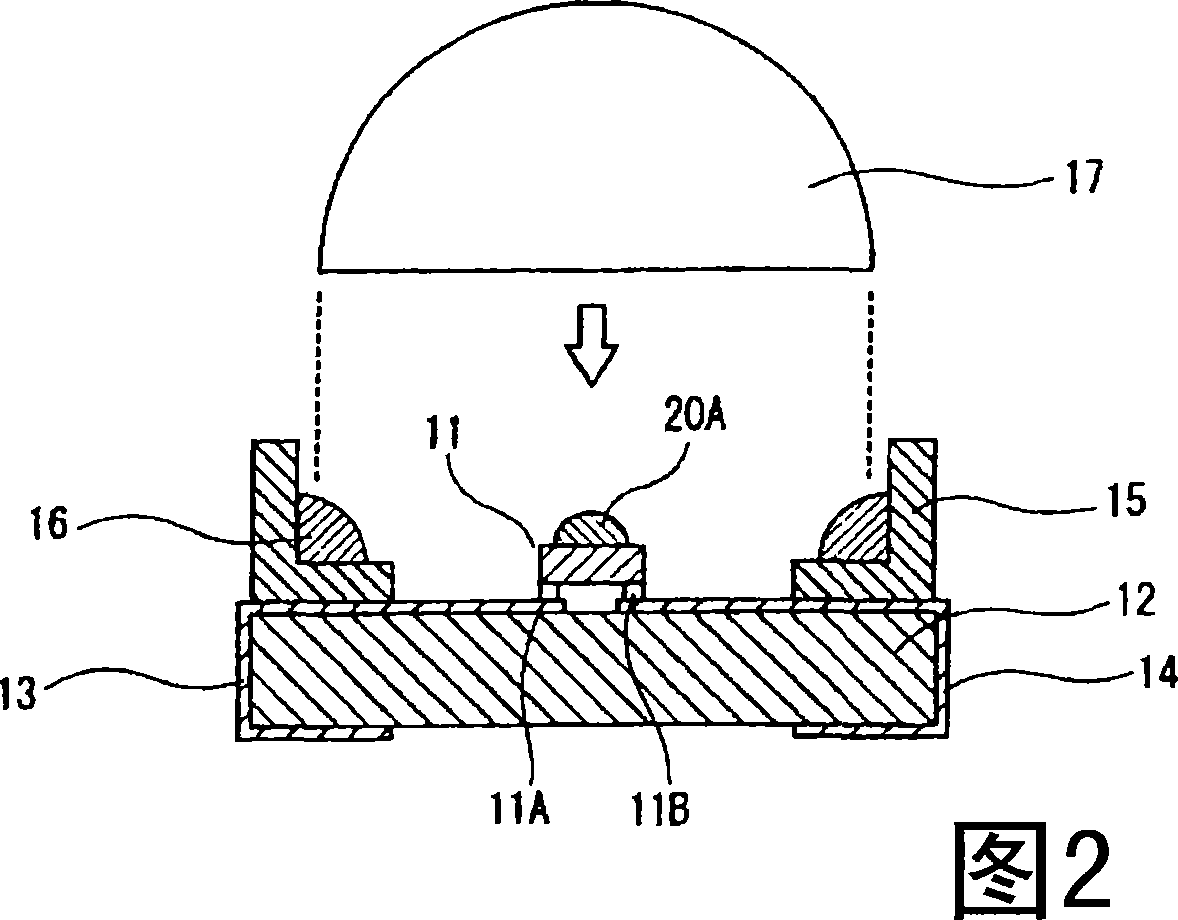

[0065] FIG. 1 is a schematic cross-sectional view showing the structure of one example of the ultraviolet light emitting device package of the present invention.

[0066] The ultraviolet light-emitting element package 10 emits ultraviolet light by being supplied with electric power. Light emitting direction front (upper in Fig. 1), the hemispherical condensing lens 17 that condenses the ultraviolet ray that emits from UV-LED element 11, separates the bottom surface and the light-emitting surface of UV-LED element 11 In the state of opening to form a gap of a predetermined size, it is held and fixed by the lens holding member 15 arranged around the periphery of the UV-LED element 11, whereby the UV-LED element 11 and the condenser lens 17 are integrally formed. .

[0067] The UV-LED element 11 is located at the center of the bottom surface side of the condensing lens 17 , and is electrically connected to the outside through lead electrodes 13 and 14 arranged on the substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com