Preparation method of functional fabric

A functional and fabric technology, applied in the field of textile materials, can solve the problems of unsatisfactory anti-wrinkle effect, loss of washable mechanical properties, and weak bonding, etc., to increase the anti-washing function, pollution-free ecological environment, and increase production value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of functional fabric, described preparation method is as follows:

[0029] a Preparation of functional nanoparticle composite solution

[0030] According to the following mass percentage:

[0031] Vinyl polysiloxane 30-80%

[0032] Functional nanoparticles 5-15%

[0033] Organic solvent 15-55%

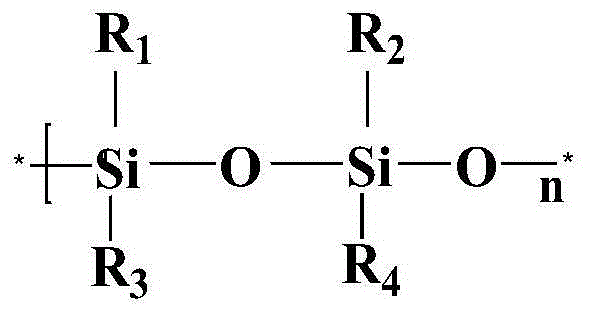

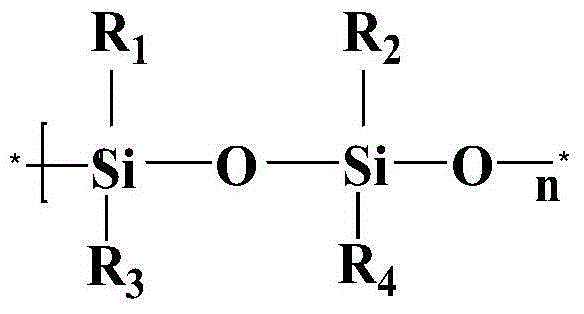

[0034] The vinyl polysiloxane is put into an organic solvent, mechanically stirred for 10 minutes, and then functional nanoparticles are added, and after ultrasonic dispersion at a temperature of 10-45° C. for 2-5 hours, a composite solution of functional nanoparticles is obtained. Wherein: the structural formula of described vinyl polysiloxane is:

[0035]

[0036] Among them: n=30-2000;

[0037] R 1 =-CH=CHR, wherein, R is -H or -OH or alkoxy (C 1 -C 5 ) or epoxy or -Cl or -Br or any of phenyl or isopropyl or pyridine or alkanone;

[0038] R 2 =methyl or phenyl or isobutyl or isooctyl or cyclopentyl or cyclohexyl or -(CH 2 ) any of n ...

Embodiment 1

[0046] The weight average molecular weight is 86500g / mol, side group R 1 , R 2 , R 3 , R 4 Respectively -CH=CH 2 ,-CH 3 , -OH, -OH vinylpolysiloxane, Fe with a particle size of 50nm 3 o 4 , the anhydrous methanol solution is mixed according to the mass ratio of 8:0.5:1.5, and then the mixed solution is dispersed by ultrasonic waves at a temperature of 35 °C for 5 hours to obtain Fe 3 o 4 Nanoparticle suspension solution.

[0047] The woven cotton fabric and the above Fe 3 o 4 The nanoparticle suspension solution was mixed at a mass ratio of 1:50, and the mixed solution was ultrasonically treated for 12 hours, and the fabric was taken out and dried in an oven at 35°C at low temperature; finally, the dried woven cotton fabric was dried at 120 Bake at ℃ for 10 minutes to obtain a functional fabric. The woven cotton fabric not only has UV protection and anti-fouling properties, but also due to Fe 3 o 4 Coated on the surface of woven cotton fabric, under the action of ...

Embodiment 2

[0049] The weight average molecular weight is 62700g / mol, side group R 1 , R 2 , R 3 , R 4 Respectively -CH=CHOH, -C 6 h 5 ,-OCH 3 ,-OCH 3 Vinyl polysiloxane, carbon nanotubes with a particle size of 62nm, and anhydrous ethanol solution are mixed at a mass ratio of 8:0.5:1.5, and then the mixed solution is dispersed by ultrasonic waves at a temperature of 35°C for 5 hours to obtain carbon nanotubes. Tube nanoparticle suspension solution.

[0050] Mix the hemp fabric and the suspension solution of carbon nanotube nanoparticles at a mass ratio of 1:50, and the mixed solution is ultrasonically treated for 12 hours, and the fabric is taken out and dried in an oven at 35°C at low temperature; finally, the dried The final hemp fabric was baked at 120° C. for 10 minutes to obtain a functional fabric. The hemp fabric not only has ultraviolet protection and anti-fouling properties, but also can be used as a sensor because the carbon nanotubes are coated on the surface of the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com