Quick preparation method for graphene oxide film

A technology of graphene film and stone oxide, which is applied in the field of rapid preparation of graphene oxide film, and can solve problems such as complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

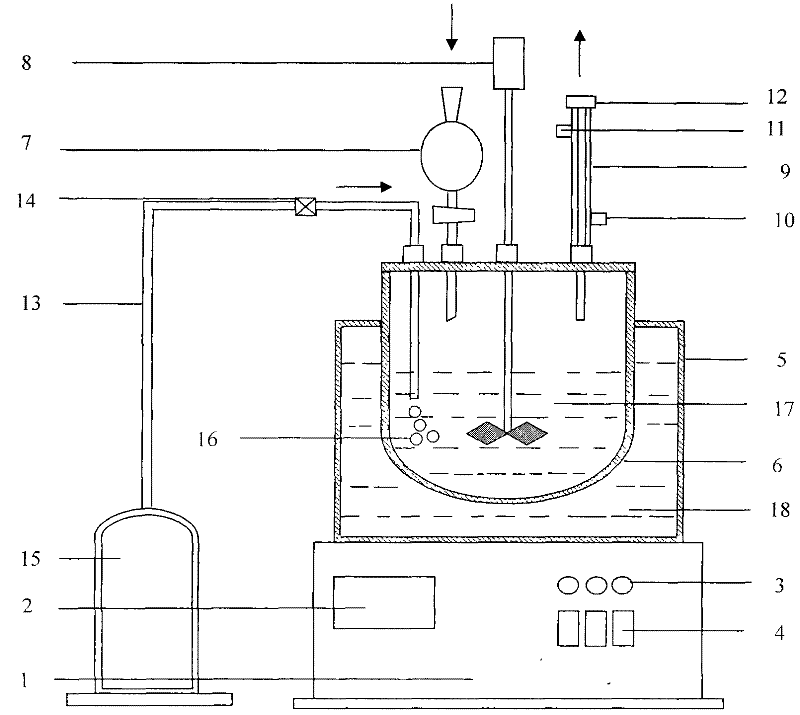

[0060] The present invention will be further explained below in conjunction with the drawings:

[0061] figure 1 Shown is the graphene oxide solution preparation state diagram, the positions of each part should be correct, proportioning according to the quantity, and operation in order.

[0062] The chemical materials required for preparation are determined according to the preset range, in grams, milliliters, millimeters, centimeters 3 It is the unit of calculation.

[0063] The preparation of the graphene oxide solution is carried out in a four-necked flask. The electric heating controller 1 is equipped with a display screen 2, an indicator light 3, and a control switch 4. The upper part of the electric heating controller 1 is an oil bathtub 5 with a built-in oil bathtub 5 Put the four-necked flask 6, the upper part of the four-necked flask 6 is set up in sequence from left to right with nitrogen pipe 13, adding funnel 7, stirrer 8, water circulation condenser pipe 9, water inlet 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com