Annular component fabricating method, die for use in such fabricating method and annular component fabricated thereby

A technology of ring-shaped parts and ring-shaped recesses, which is applied in the manufacturing field of ring-shaped parts, can solve the problems of increased production process space or surface area in the middle of inventory costs, decreased productivity, and difficulty in shortening delivery dates, etc., to achieve shortened processing time, Productivity improvement and equipment cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

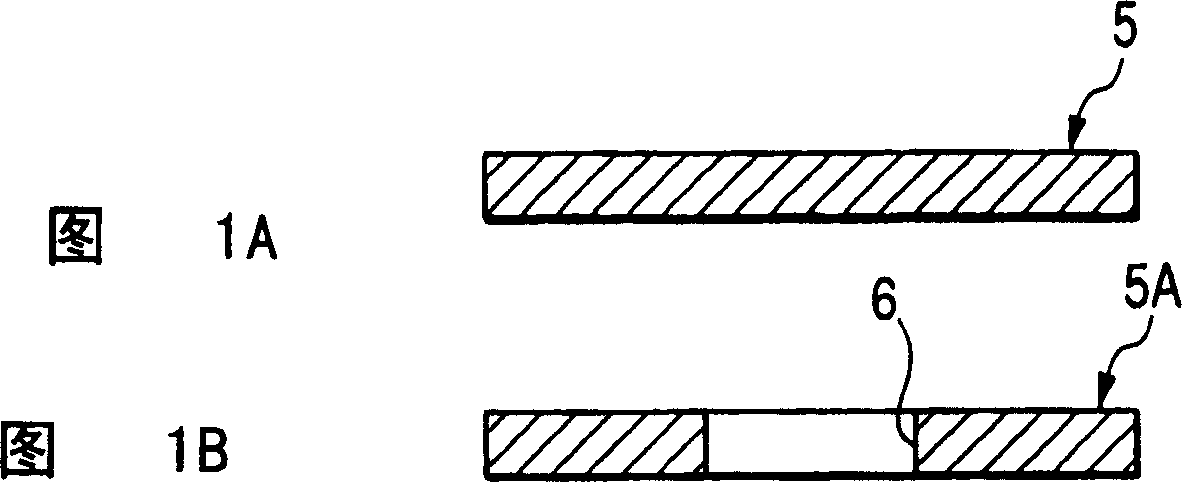

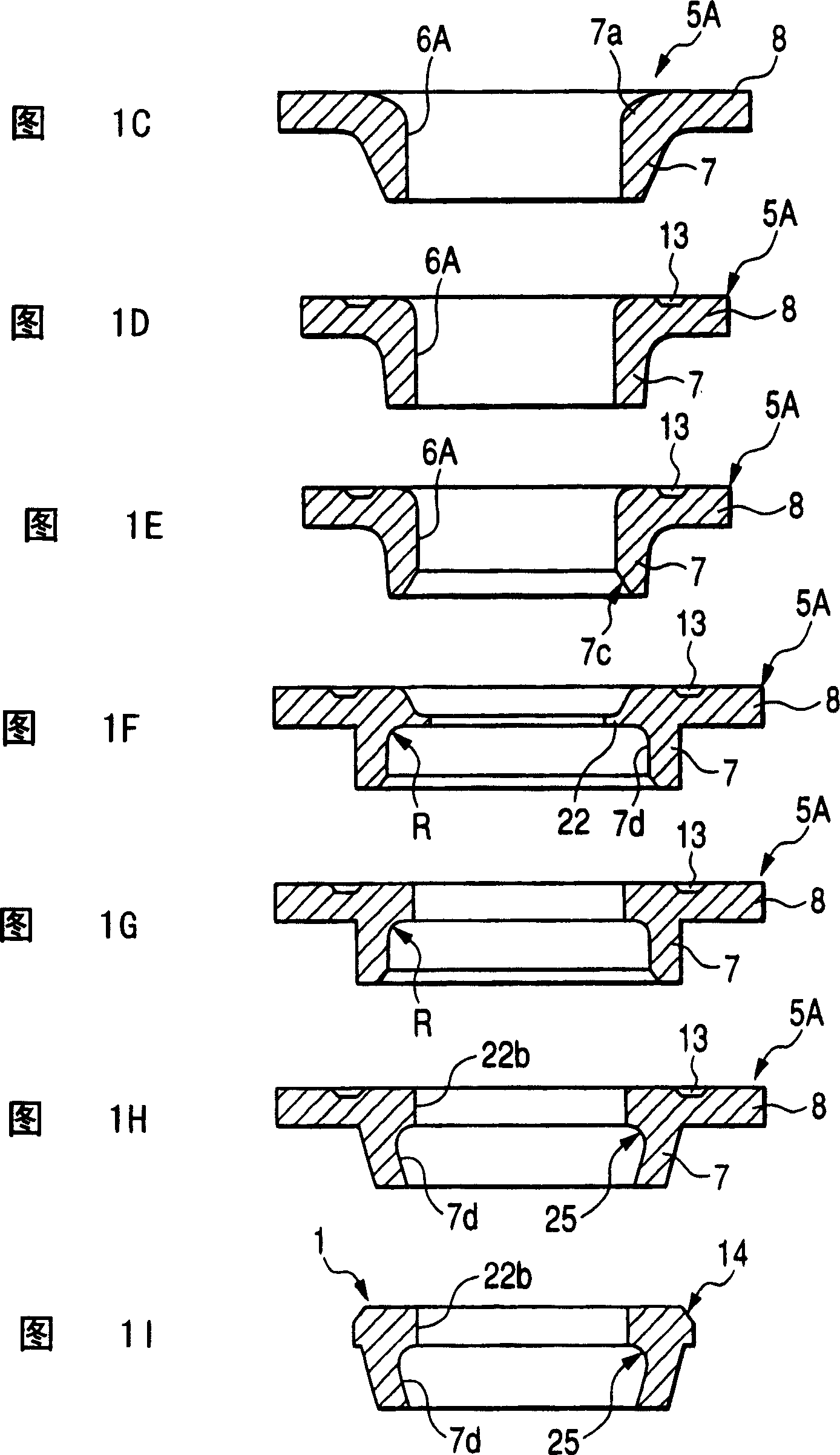

[0080] 1A-1I show flow charts for carrying out the method of manufacturing the annular component 1 .

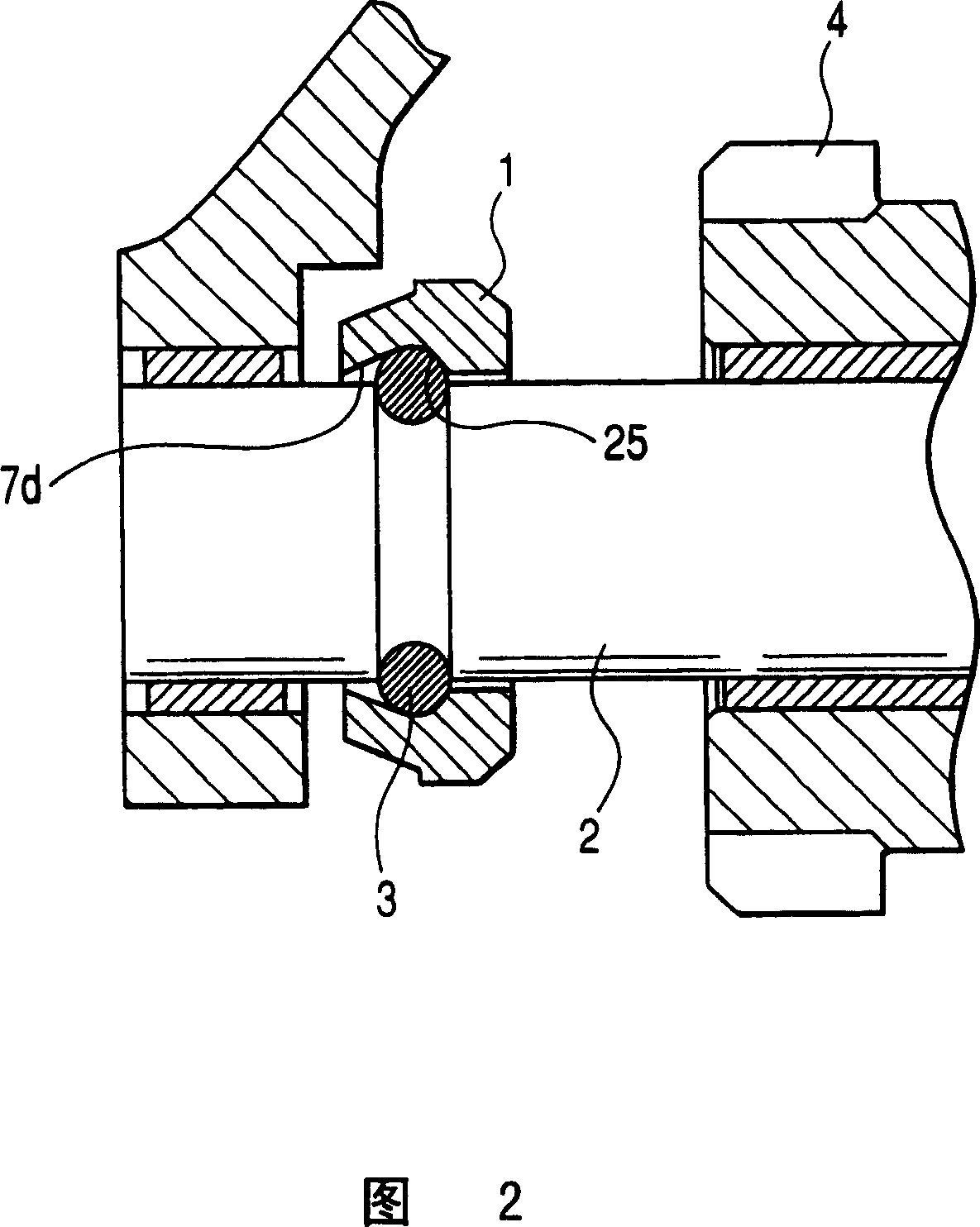

[0081] As shown in FIG. 2 , the annular member 1 of the first embodiment performs, for example, the function of a stop ring 1 which is mounted on the engine starting ring 3 by means of a snap ring 3 fitted to the outer circumference of the output shaft 2 . on output shaft 2 of the starter. The output shaft 2 carries thereon a slidable pinion 4 which is movable towards (to the left in FIG. 2 ) a ring gear (not shown) of the engine. The stop ring 1 is used as a movement limiting element, which limits the position in which the pinion 4 can move in the axial direction.

[0082] Now, a method of manufacturing an annular component 1 according to an embodiment of the present invention will be described with reference to FIGS. 1A-1I and FIGS. 3-10 . Figures 3, 5, 7 and 9 show the states in which the relevant upper dies are lifted upward when the respective processing is completed. ...

no. 2 example

[0130] Fig. 11 is a cross-sectional view of an annular member 1 (stop ring) obtained by the annular member manufacturing method according to the second embodiment of the present invention.

[0131] Although in the first embodiment, the extruding operation is performed using the tapered extruding punch 24 as shown in FIG. 9 , the second embodiment is characterized in that the extruding operation is performed using the roller 26 as shown in FIG. 11 . That is, the roller 26 held in an abutting engagement relationship with the outer peripheral wall 7b of the cylindrical wall 7 of the workpiece 5A rotates to cause the cylindrical wall 7 to gradually deform into a tapered shape.

[0132] Also, the second embodiment has the same steps as the first embodiment except for the pressing operation. Even with the method of the second embodiment, it is not necessary to use a cutting process to form the inner diameter recess 25 constituting the cut groove. In addition, the manufacturing meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com