Preparation method for large-specification TC4 titanium alloy ring piece

A titanium alloy, large-scale technology, applied in the field of preparation of large-scale TC4 titanium alloy rings, can solve the problems of affecting the mechanical properties of finished products, low material utilization, uneven structure, etc., to improve material utilization and fully deform the material The effect of uniformity and improvement of material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

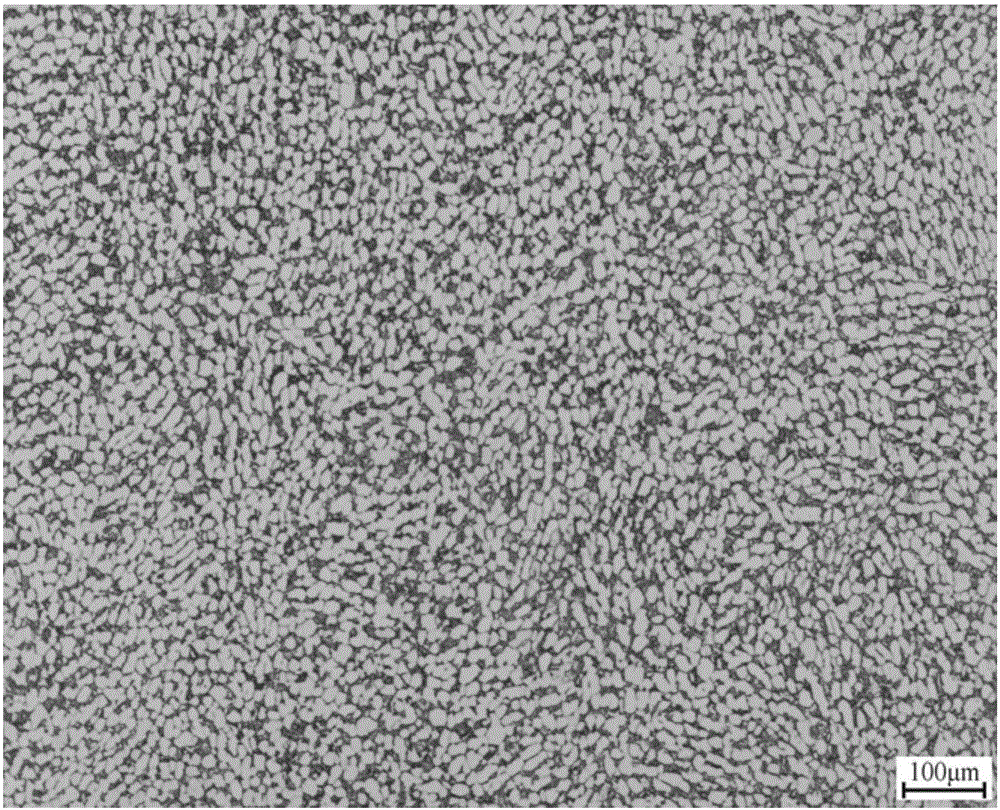

Embodiment 1

[0027] The preparation method of the large-scale TC4 titanium alloy ring of the present embodiment comprises the following steps:

[0028] Step 1. Heating the TC4 titanium alloy billet with a circular cross section and a specification of Ф400×350mm to the process temperature and keeping it warm, and then performing two-upsetting and two-drawing forging. 1 = heating coefficient η 1 ×δ 1 ,δ 1 Be the cross-sectional diameter of described TC4 titanium alloy billet, unit is mm, heating coefficient η 1 =0.6, holding time t 1 =240min; the deformation of each upsetting during the two-upsetting and two-drawing forging process is 50%, the final forging temperature of the two-upsetting and two-drawing forging is not lower than 800°C, and after the two-upsetting and two-drawing forging The TC4 titanium alloy blank returns to its original height; the initial microstructure of the TC4 titanium alloy blank is α 等轴 +β 转变 Two-phase structure, the process temperature is 20°C below the tra...

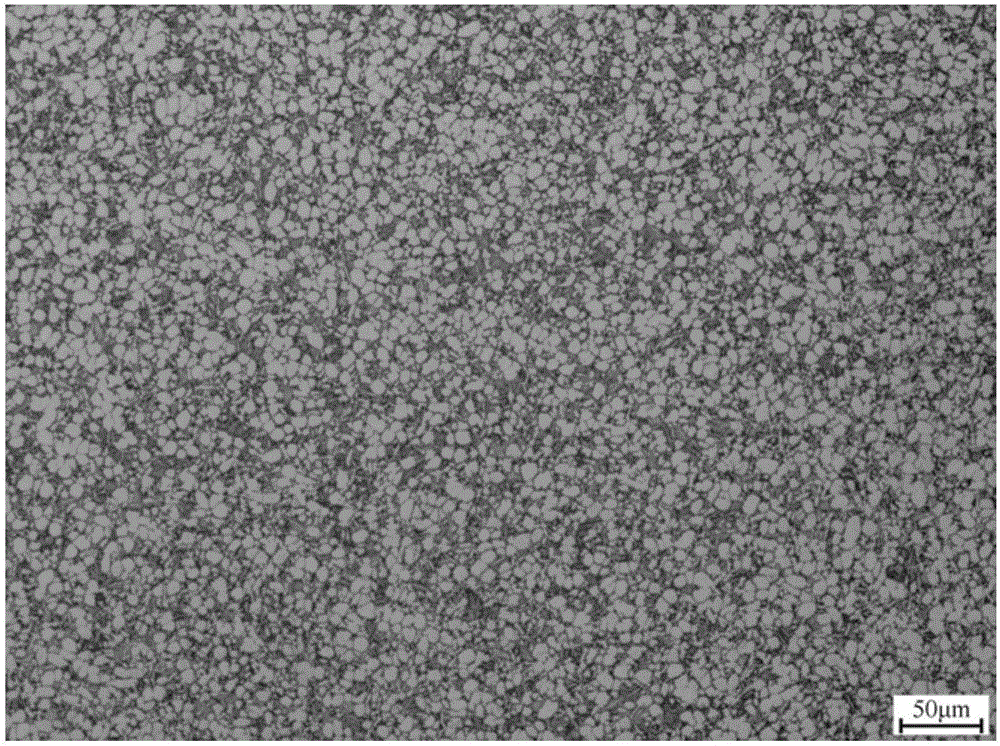

Embodiment 2

[0040] The preparation method of the large-scale TC4 titanium alloy ring of the present embodiment comprises the following steps:

[0041] Step 1. Heating the TC4 titanium alloy billet with a circular cross section and a specification of Ф350×280mm to the process temperature and keeping it warm, and then performing two-upsetting and two-drawing forging. 1 = heating coefficient η 1 ×δ 1 ,δ 1 Be the cross-sectional diameter of described TC4 titanium alloy billet, unit is mm, heating coefficient η 1 =0.6, holding time t 1 =210min; the deformation of each upsetting during the two-upsetting and two-drawing forging process is 40%, the final forging temperature of the two-upsetting and two-drawing forging is not lower than 800°C, and after the two-upsetting and two-drawing forging The TC4 titanium alloy blank returns to its original height; the initial microstructure of the TC4 titanium alloy blank is α 等轴 +β 转变 Two-phase structure, the process temperature is 50°C below the tra...

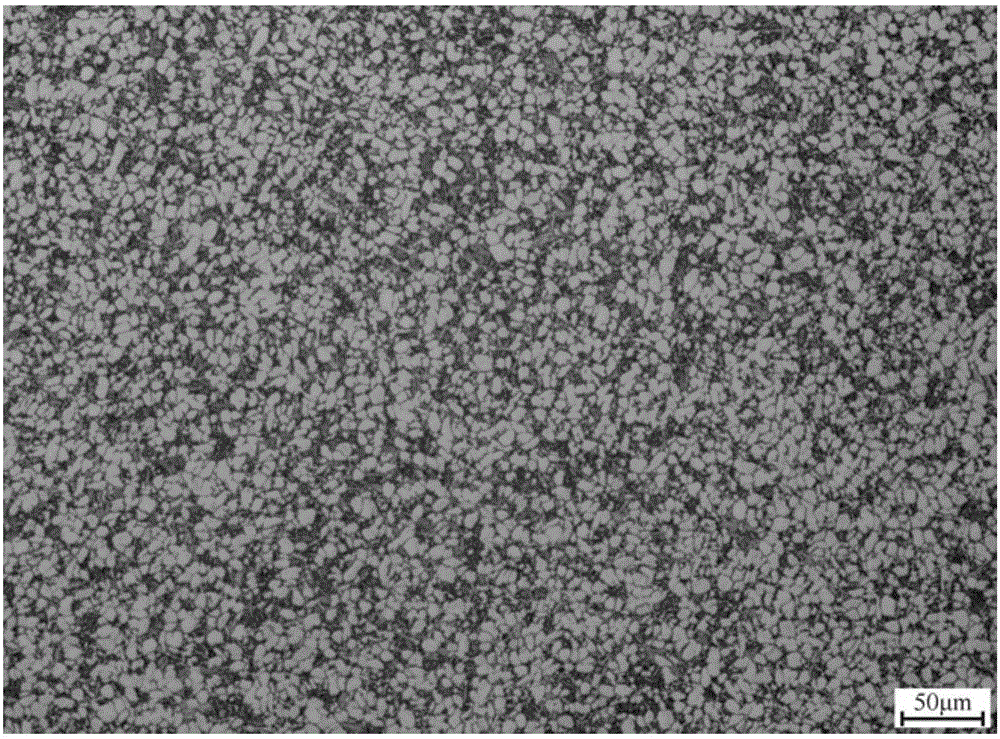

Embodiment 3

[0053] The preparation method of the large-scale TC4 titanium alloy ring of the present embodiment comprises the following steps:

[0054] Step 1. Heating the TC4 titanium alloy billet with a circular cross section and a specification of Ф390×360mm to the process temperature and keeping it warm, and then performing two-upsetting and two-drawing forging. 1 = heating coefficient η 1 ×δ 1 ,δ 1 Be the cross-sectional diameter of described TC4 titanium alloy billet, unit is mm, heating coefficient η 1 =0.8, holding time t 1 =312min; the deformation of each upsetting during the two-upsetting and two-drawing forging process is 60%, the final forging temperature of the two-upsetting and two-drawing forging is not lower than 800°C, and after the two-upsetting and two-drawing forging The TC4 titanium alloy blank returns to its original height; the initial microstructure of the TC4 titanium alloy blank is α 等轴 +β 转变 Two-phase structure, the process temperature is 30°C below the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com