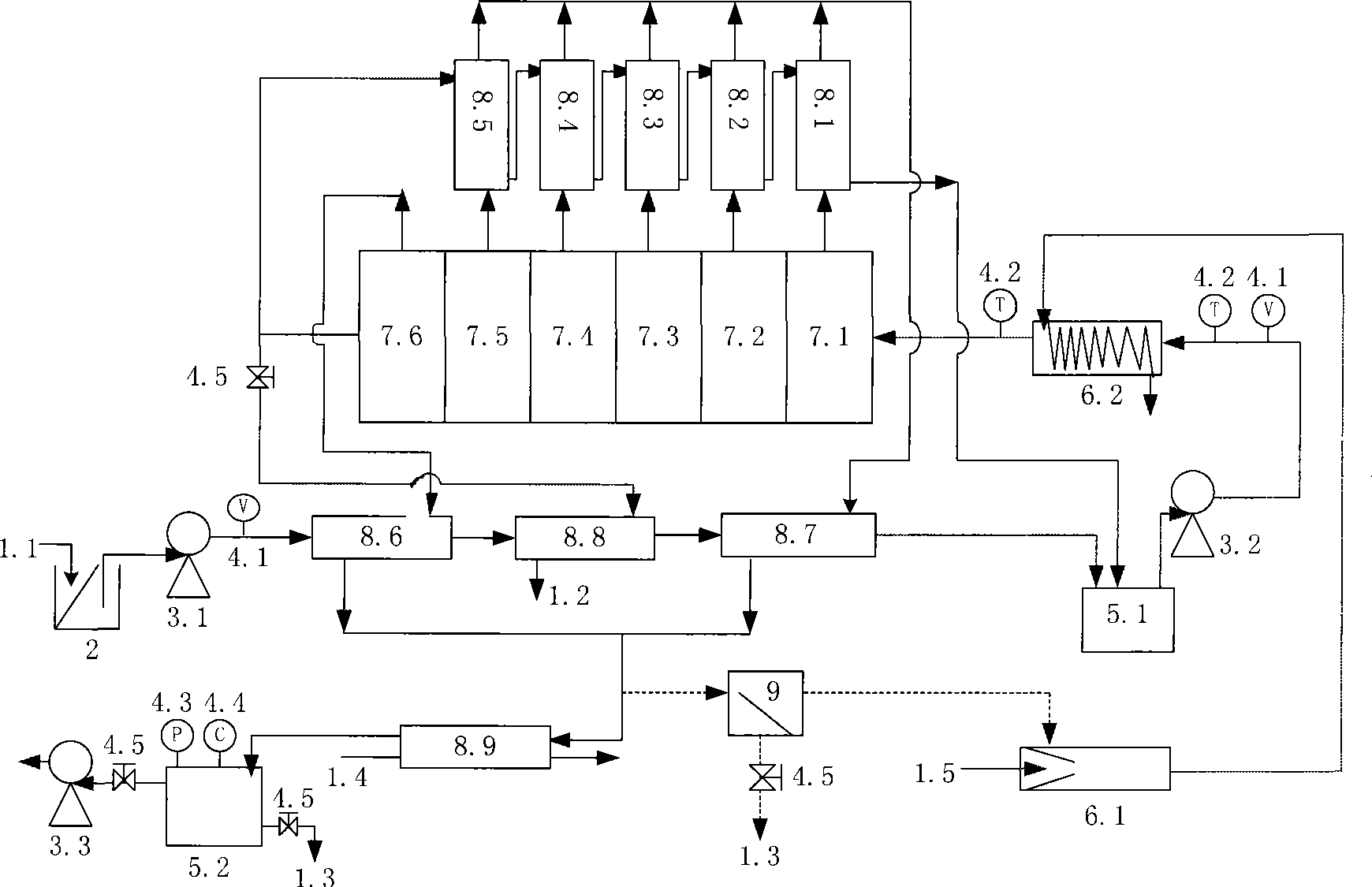

Energy-saving pressure-reduction distillation device and method

A decompression membrane distillation, membrane distillation technology, applied in the direction of pervaporation, etc., can solve the problem of unsuitable cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Material aqueous solution: sea water

[0041] Pretreatment: sedimentation, sand filtration, microfiltration

[0042] Membrane and membrane module: polypropylene hollow fiber membrane, plate and frame cross-flow membrane module structure

[0043] Heat recovery device: shell and tube titanium heat exchanger, steam jet heat pump

[0044] Heating: The heat source is the exhaust steam of the thermal power plant, and the inlet temperature of the membrane module of the material liquid is 90°C

[0045] Results: The product is distilled water, 12% saline concentrated seawater, and the heat recovery rate is 85%.

Embodiment 2

[0047] Material aqueous solution: dilute sulfuric acid, hydrochloric acid industrial wastewater

[0048] Pretreatment: microfiltration

[0049] Membrane and membrane module: polytetrafluoroethylene hollow fiber membrane, shell and tube membrane module structure

[0050] Heat recovery device: plastic material heat exchanger, steam jet heat pump

[0051] Heating: low-pressure steam, the inlet temperature of the membrane module of the material liquid is 85°C

[0052] Results: The products are distilled water and high-concentration acid-containing aqueous solution, and the heat recovery rate is 80%.

Embodiment 3

[0054] Material aqueous solution: 8% ethanol aqueous solution

[0055] Pretreatment: microfiltration

[0056] Membrane and membrane module: polyvinylidene fluoride flat membrane, roll type laminar flow module structure

[0057] Heat recovery device: copper plate heat exchanger

[0058] Heating: cooling tower heat exchange, the inlet temperature of the membrane module of the material liquid is 65°C

[0059] Results: The product is a 95% ethanol solution, and the heat recovery rate is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com