Super-hydrophobic electrostatic spinning polydimethylsiloxane membrane and preparation method and application thereof

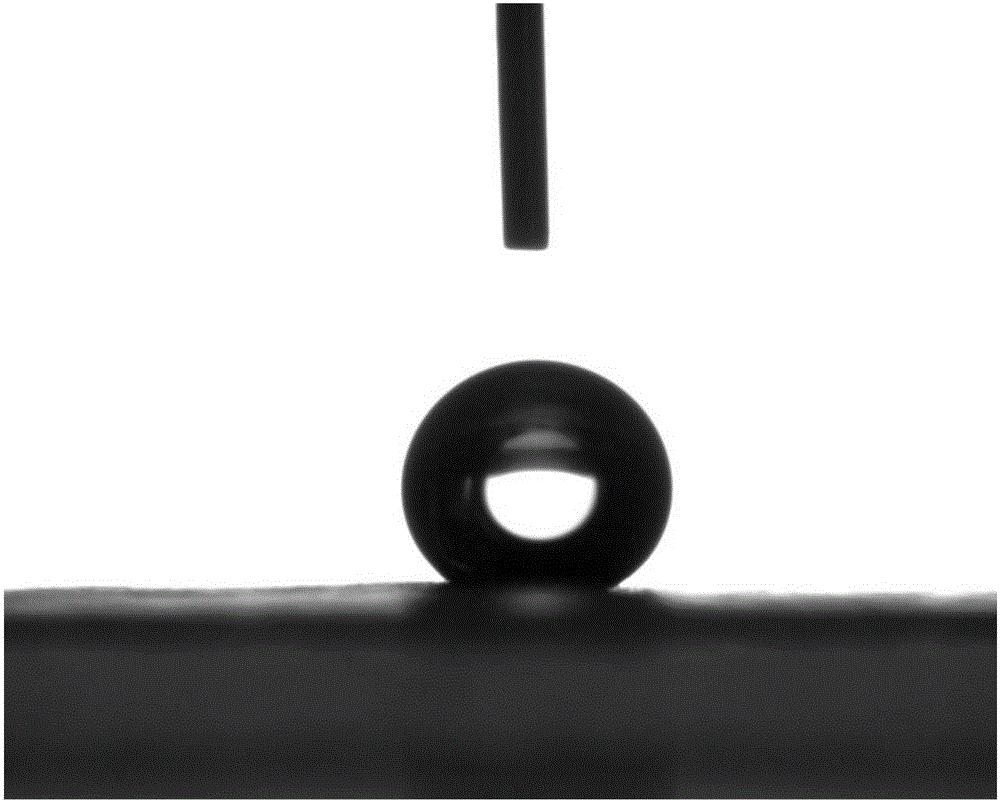

A technology of dimethylsiloxane film and electrospinning, which is applied in the field of preparation of superhydrophobic electrospinning polydimethylsiloxane film, can solve the problems of low hydrophobicity and uncontrollable pore size, and achieve anti-wetting The effect of high wettability, controllable membrane pore size, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

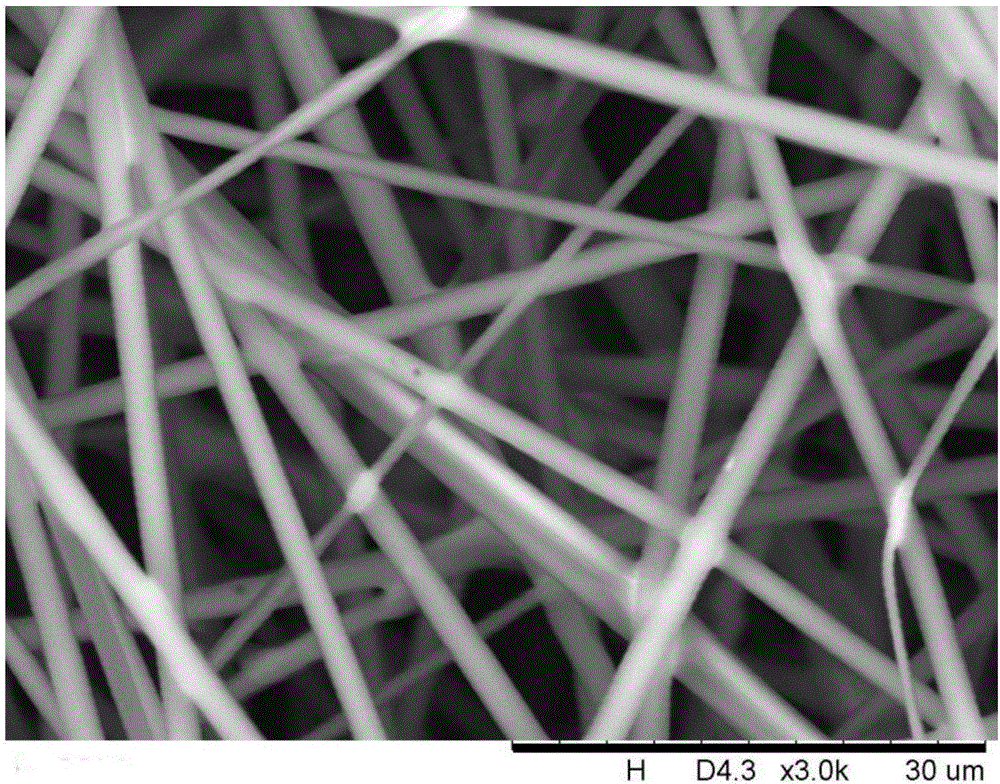

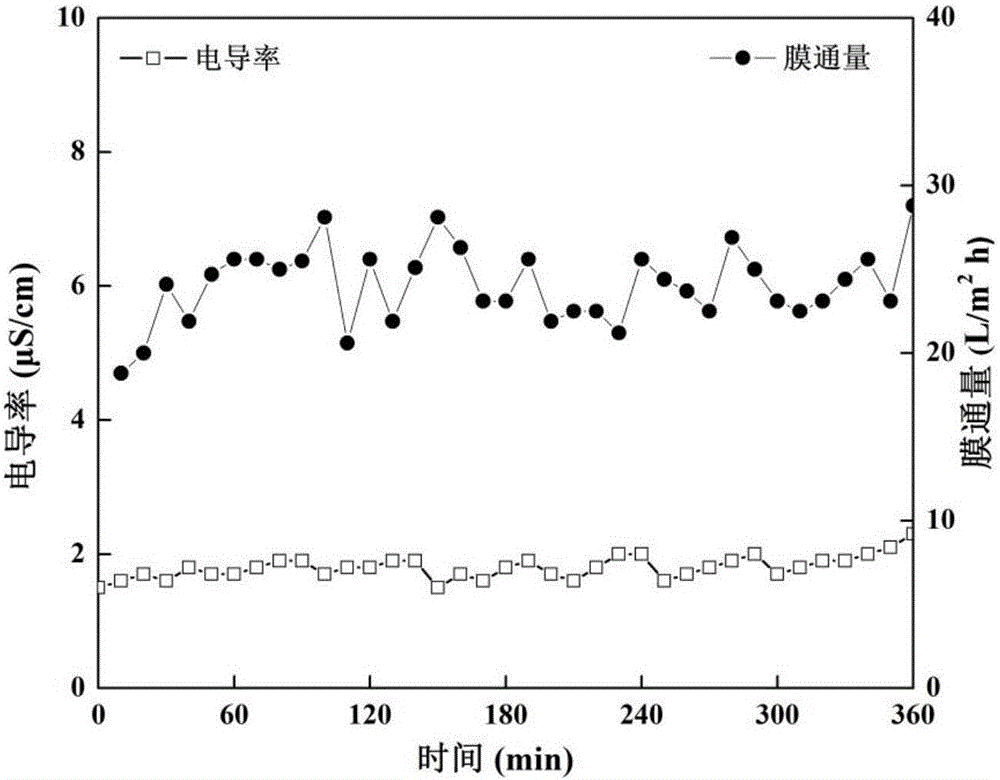

[0034] This embodiment provides a method for preparing a superhydrophobic electrospun polydimethylsiloxane membrane suitable for a membrane distillation process, comprising the following steps:

[0035] (1) Preparation of electrospinning base solution: Dissolve PMMA in a mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) with a mass ratio of 1:1, and stir at 50°C for 2h; Wherein the mass percent of PMMA in the mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) is 10wt.%;

[0036] (2) Preparation of electrospinning solution: add PDMS of corresponding quality to the above-mentioned electrospinning base liquid, so that the mass percentage of PDMS in the electrospinning base liquid is 10wt.%, stir at 25°C for 0.5h, and then Stand at 25°C for 0.5h to obtain the electrospinning solution;

[0037](3) Set the electrospinning parameters, and electrospin the electrospinning solution to form a film to obtain an electrospun polydimethylsiloxane fil...

Embodiment 2

[0042] This embodiment provides a method for preparing a superhydrophobic electrospun polydimethylsiloxane membrane suitable for a membrane distillation process, comprising the following steps:

[0043] (1) Preparation of electrospinning base solution: Dissolve PMMA in a mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) with a mass ratio of 1:1, and stir at 50°C for 2h; Wherein the mass percent of PMMA in the mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) is 15wt.%;

[0044] (2) Prepare electrospinning solution: add PDMS of corresponding quality in PMMA electrospinning base liquid, make the mass percent of PDMS in electrospinning base liquid be 15wt.%, stir 0.5h at 50 ℃, then in Stand at 50°C for 0.5h to obtain the electrospinning solution;

[0045] (3) Set the electrospinning parameters, and electrospin the electrospinning solution to form a film to obtain an electrospun polydimethylsiloxane film, wherein the electrospinning param...

Embodiment 3

[0050] This embodiment provides a method for preparing a superhydrophobic electrospun polydimethylsiloxane membrane suitable for a membrane distillation process, comprising the following steps:

[0051] (1) Preparation of electrospinning base solution: dissolve TPU in a mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) with a mass ratio of 1:1, and stir at 70°C for 2h; Wherein the mass percent of TPU in the mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) is 10wt.%;

[0052] (2) Preparation of electrospinning solution: add PDMS of corresponding quality to the above-mentioned electrospinning base liquid, so that the mass percentage of PDMS in the electrospinning base liquid is 10wt.%, stir at 25°C for 0.5h, and then Stand at 25°C for 0.5h to obtain the electrospinning solution;

[0053] (3) Set the electrospinning parameters, and electrospin the electrospinning solution to form a film to obtain an electrospun polydimethylsiloxane film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Initial conductivity | aaaaa | aaaaa |

| Initial conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com