Nanofiber membrane for membrane distillation and preparation method of nanofiber membrane

A nanofiber membrane and nanofiber technology, which is applied in the field of membrane distillation, can solve the problems that the long-term stable operation of the membrane distillation process cannot be guaranteed, the hydrophobic performance of the membrane is unstable, and the flux of the membrane membrane is not ideal. Excellent effect with simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

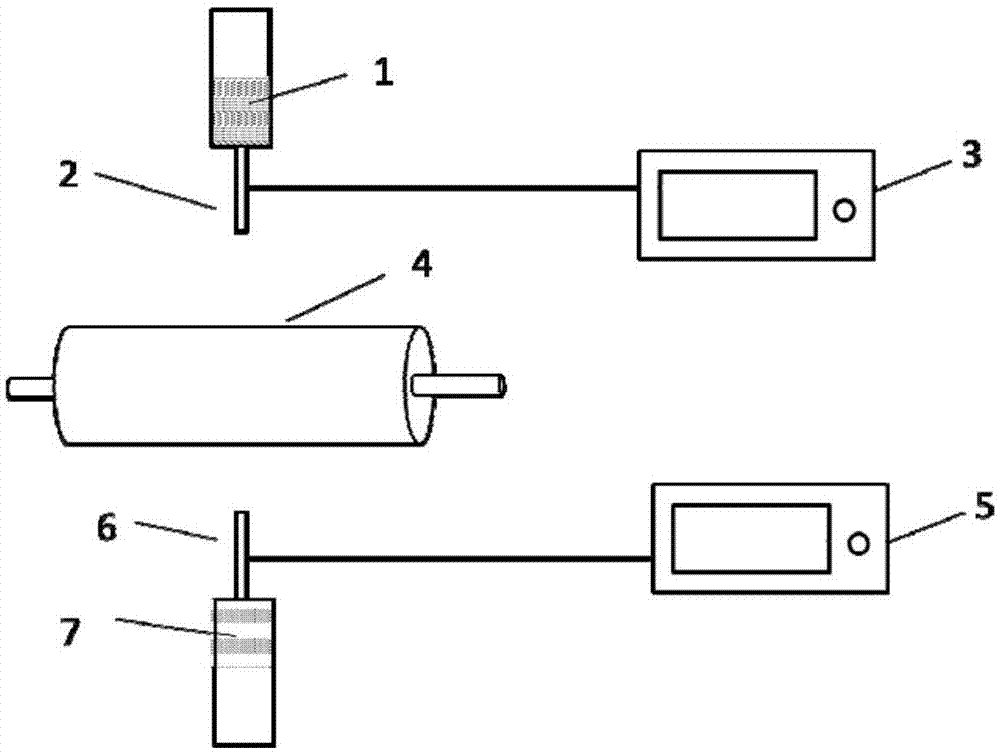

[0054] This embodiment adopts as figure 1 The shown device carries out the preparation of the nanofiber membrane used for membrane distillation, and described device comprises electrospinning solution 1, electrospinning device 2, electrospinning power supply 3, receiving device 4, electrostatic spraying power supply 5, electrostatic spraying device 6 and Electrostatic spray liquid7.

[0055] The preparation method is as follows:

[0056] (1) Dissolving 20 parts of polyvinylidene fluoride in 24 parts of acetone and 56 parts of dimethylacetamide to prepare an electrospinning solution;

[0057] (2) 5 parts of hydrophobic nano-silicon dioxide are uniformly dispersed in 95 parts of dimethylformamide to prepare a spray liquid;

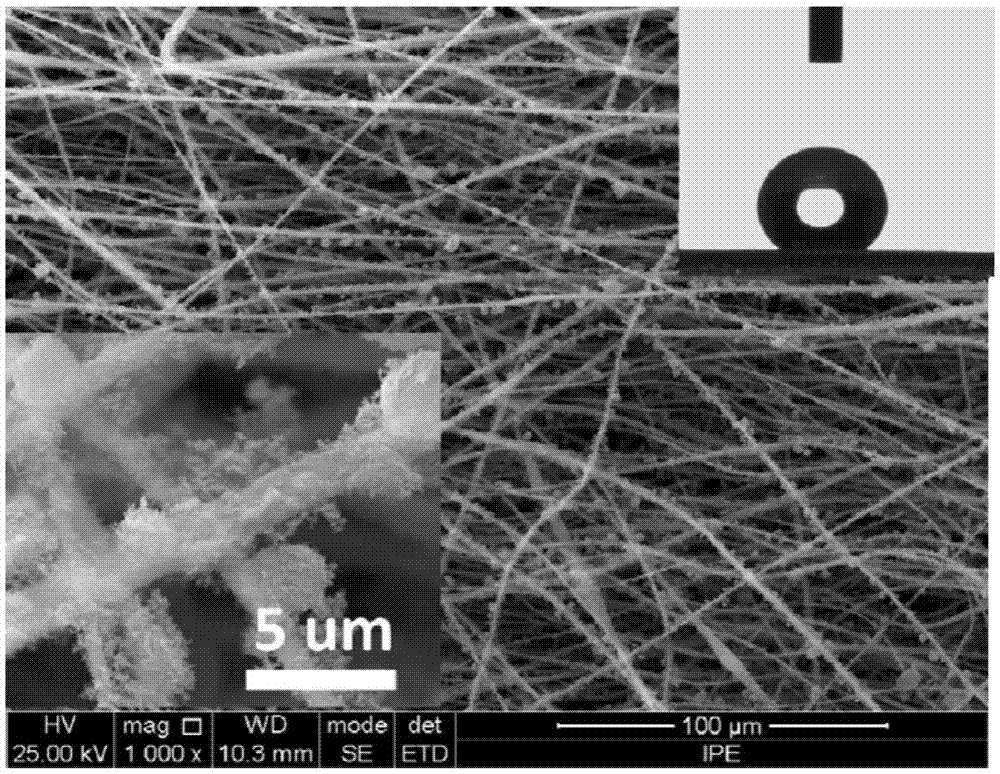

[0058] (3) The electrospinning solution prepared in step (1) is packed into the electrospinning device, and the spray solution prepared in step (2) is packed into the electrostatic spray device, and the consumption ratio of the spray solution and the elect...

Embodiment 2

[0061] In this embodiment, the following method is used to prepare nanofiber membranes for membrane distillation:

[0062] (1) Dissolving 25 parts of polyvinylidene fluoride in 75 parts of dimethylacetamide to prepare an electrospinning solution;

[0063] (2) 10 parts of hydrophobic nano-silica are uniformly dispersed in 90 parts of dimethylformamide to prepare a spraying liquid;

[0064] (3) The electrospinning solution prepared by step (1) is loaded into the electrospinning device, and the spraying solution prepared by step (2) is packed into the air spraying device, and the consumption ratio of the spraying solution and the electrospinning solution is 1 :2, set the electrospinning liquid injection flow rate to 2.0ml h -1 , set the injection flow rate of the air spraying device to 0.8ml h -1 ; Set the spinning voltage as 10kV, the receiving distance of the receiver as 15cm, and the spraying distance between the air spraying device and the receiver as 10cm. The electrospin...

Embodiment 3

[0067] In this embodiment, the following method is used to prepare nanofiber membranes for membrane distillation:

[0068] (1) Dissolving 20 parts of polyvinylidene fluoride in 85 parts of dimethylacetamide to prepare an electrospinning solution;

[0069] (2) uniformly dispersing 15 parts of hydrophobic nano silicon dioxide in 90 parts of dimethylformamide to prepare a spraying liquid;

[0070] (3) The electrospinning solution prepared in step (1) is loaded into the electrospinning device, and the spraying solution prepared in step (2) is loaded into the electrostatic spraying device, and the consumption ratio of the spraying solution and the electrostatic spinning solution is 1 :20, set the electrospinning liquid injection flow rate to 2.0ml h -1 , set the injection flow rate of electrostatic spraying liquid to 0.8ml h -1 ; Set the spinning voltage as 15kV, the receiving distance of the receiver as 20cm, the spraying distance between the electrostatic spraying device and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com