Method for treating high salinity wastewater

A technology of high-salt wastewater and treatment method, which is applied in the fields of water/sewage multi-stage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. and other problems, to achieve the effect of reducing membrane pollution, solving the problem of fast flux decay rate and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

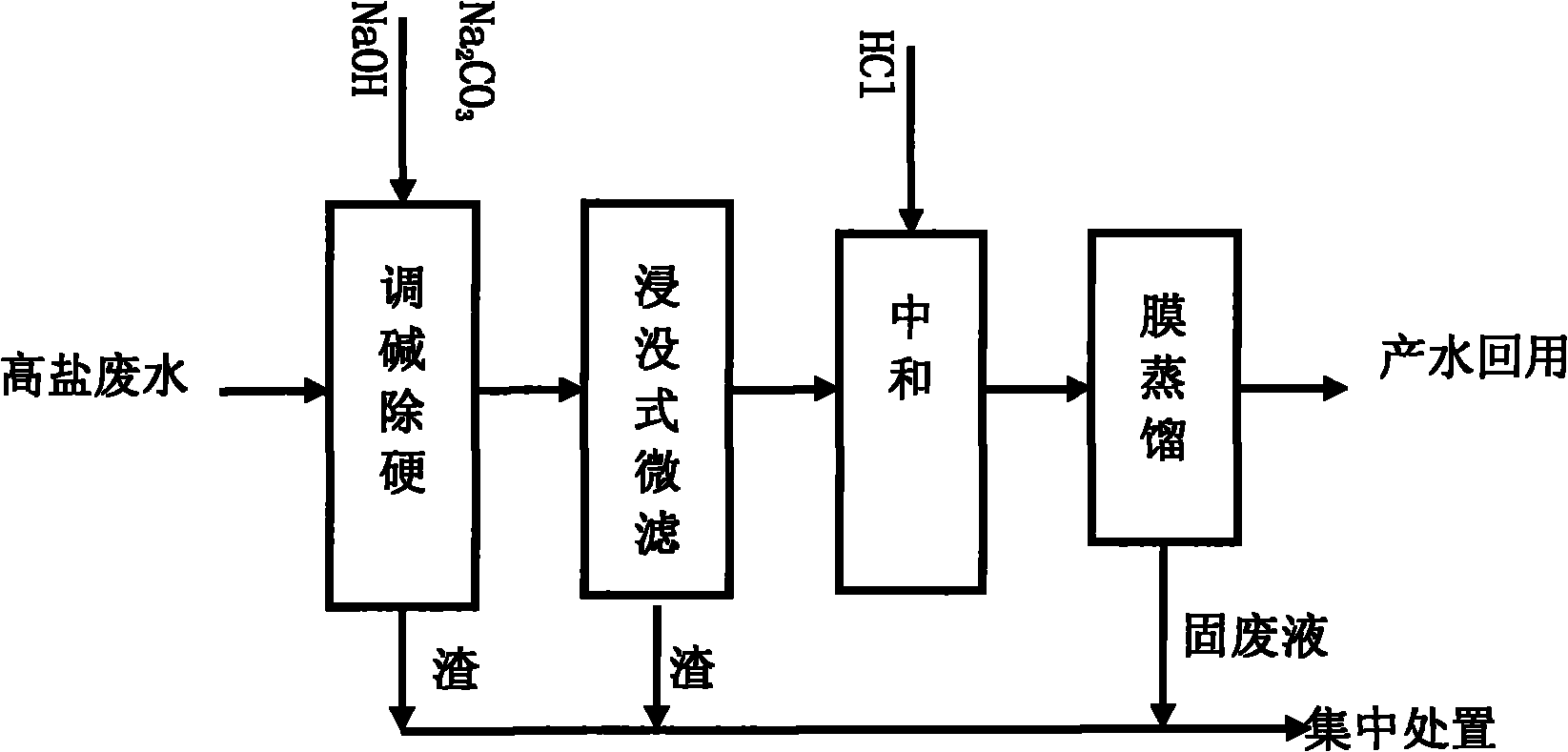

Method used

Image

Examples

Embodiment 1~4

[0027] (1) Add NaOH and Na to reverse osmosis concentrated water 2 CO 3 , adjust its pH to 10.8 (NaOH addition is 800mg / L, NaOH 2 CO 3 Addition amount is 300mg / L), after precipitation, carry out solid-liquid separation to remove calcium, magnesium hardness of waste water, removal effect is: total hardness removal 73%, calcium hardness removal 93%, magnesium hardness removal 39%;

[0028] (2) Submerged microfiltration treatment is used to remove turbidity and SS in wastewater. An aeration system is installed at the bottom of the microfiltration tank to reduce membrane surface pollution through aeration and shaking of membrane filaments; Hollow fiber membrane, the operating pressure of the microfiltration treatment is -0.008MPa, the operating temperature is 20°C, the pH is 10.8, and the permeation flux of the microfiltration membrane is 45-55L / m 2 h, after treatment, turbidity and SS are basically completely removed;

[0029] (3) In order to prevent unremoved calcium and mag...

Embodiment 5

[0036] Add NaOH to reverse osmosis concentrated water (addition amount 2000mg / L), adjust its pH to 11.3, and remove calcium and magnesium hardness in wastewater. The removal effect is: 97% of total hardness removal, almost all calcium hardness removal, and magnesium hardness removal 95%;

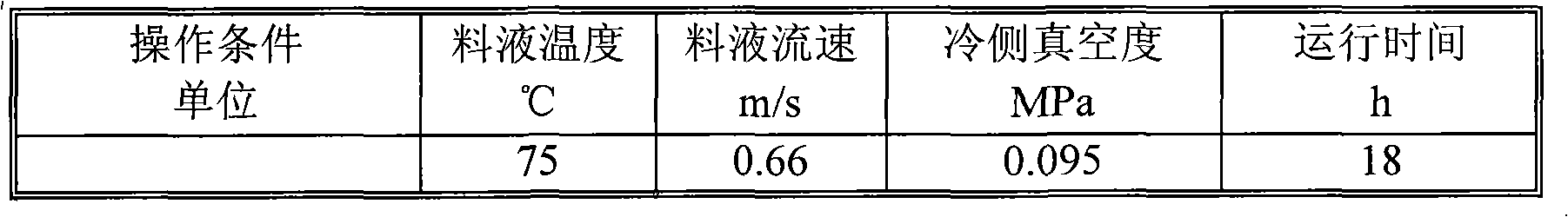

[0037] Other treatment processes are the same as in Example 1. The unit operating conditions of the vacuum membrane distillation treatment are shown in Table 4, and the treatment effects are shown in Table 5.

[0038] Table 4

[0039]

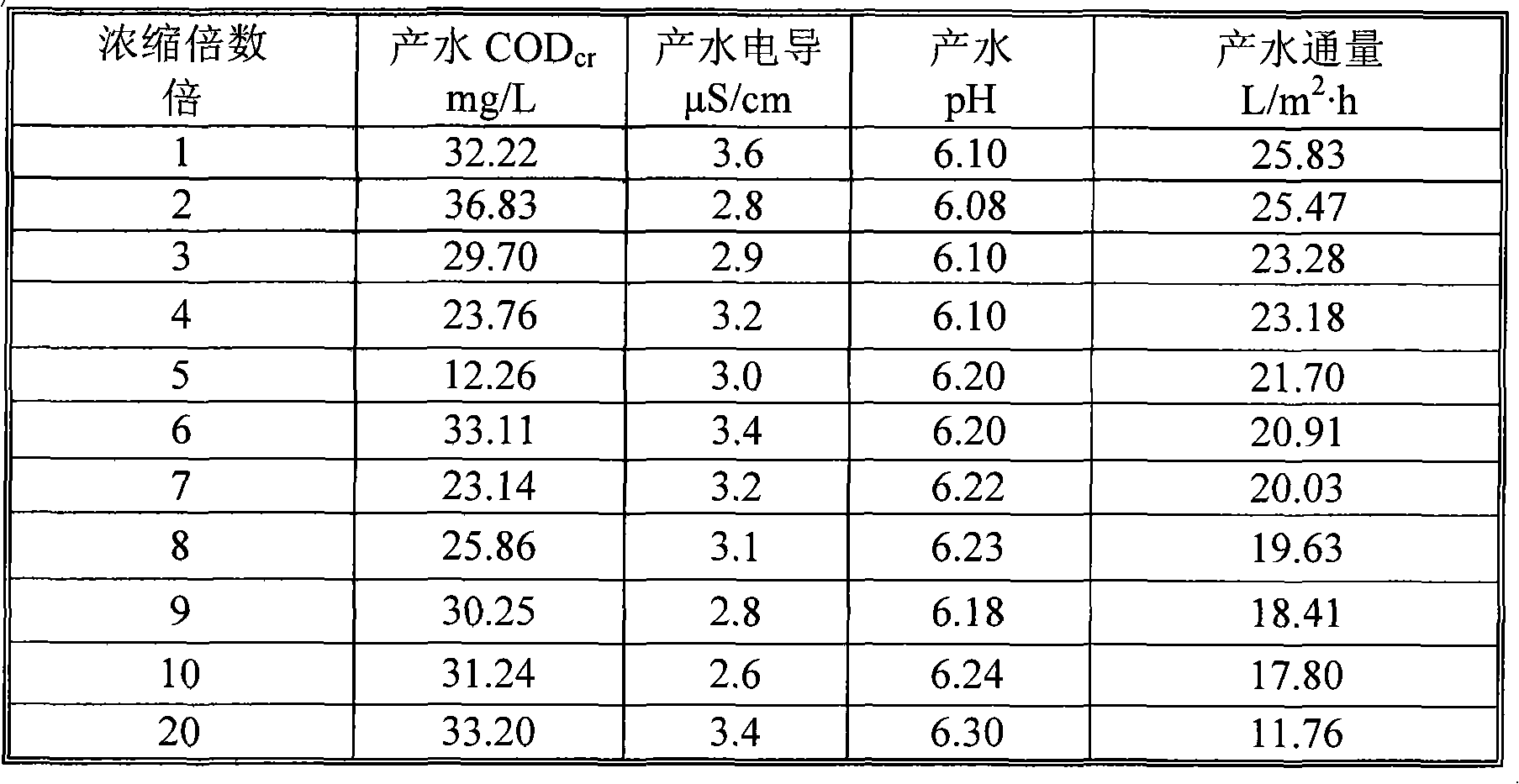

[0040] table 5

[0041]

[0042] Membrane distillation is performed on the reverse osmosis concentrated water pretreated by "alkali adjustment and hardness removal + microfiltration + neutralization", which can run continuously and stably for about 15 to 25 days, and the conductance of membrane distillation water can be kept within 4μS / cm , the desalination rate is higher than 99%, and the flux is always maintained at 5-20L / m during operation 2 · Withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com