Method for treating epoxy resin waste-water with high alkalinity, high salt and high content of organics

A treatment method, epoxy resin technology, applied in natural water treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of not considering the comprehensive recycling of energy, not considering the connection mode of membrane modules, etc. , to achieve the effect of good effluent water quality, small footprint and resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

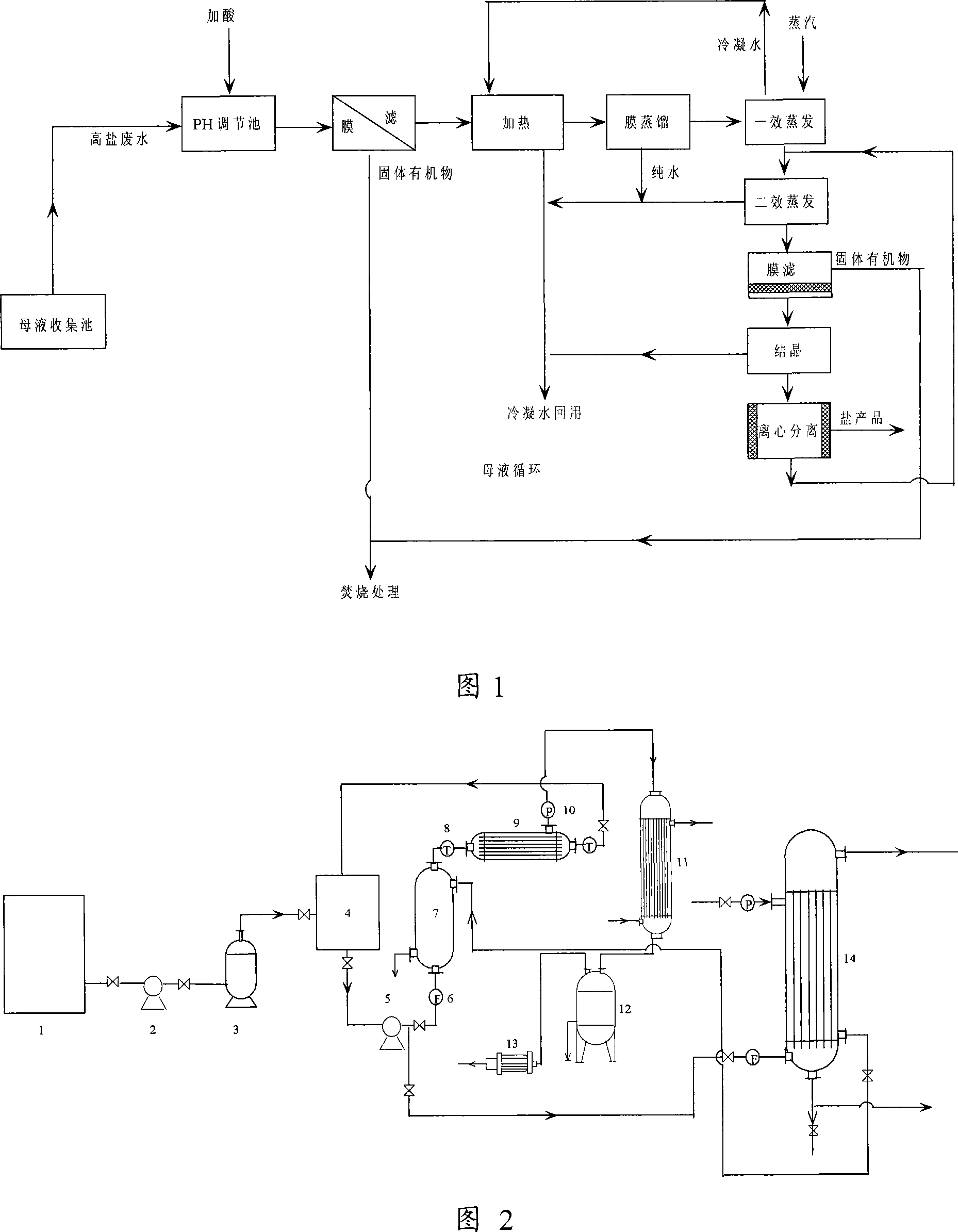

[0037] Referring to Fig. 1, after the waste water is produced from the reactor, it first enters the regulating tank, and the salt (mainly sodium chloride) degree in the waste water is 10%, and the COD is greater than 7500ppm.

[0038] Since bisphenol A and other organic impurities in wastewater are soluble in alkaline, and the solubility is very small in neutral, so the wastewater is first adjusted to neutral with hydrochloric acid, and then pumped to a filter for membrane filtration through a booster pump to remove precipitated organic matter , During membrane filtration, the wastewater flow rate is 40L / h, the permeate side vacuum is 0.08MPa, and the feed temperature is 50°C; the filtered organic matter is incinerated.

[0039] The wastewater from which precipitated organic matter has been removed enters the membrane distillation system for concentration and dehydration after being heated, and the salt concentration in the wastewater is concentrated to 20% to obtain a concentr...

Embodiment 2

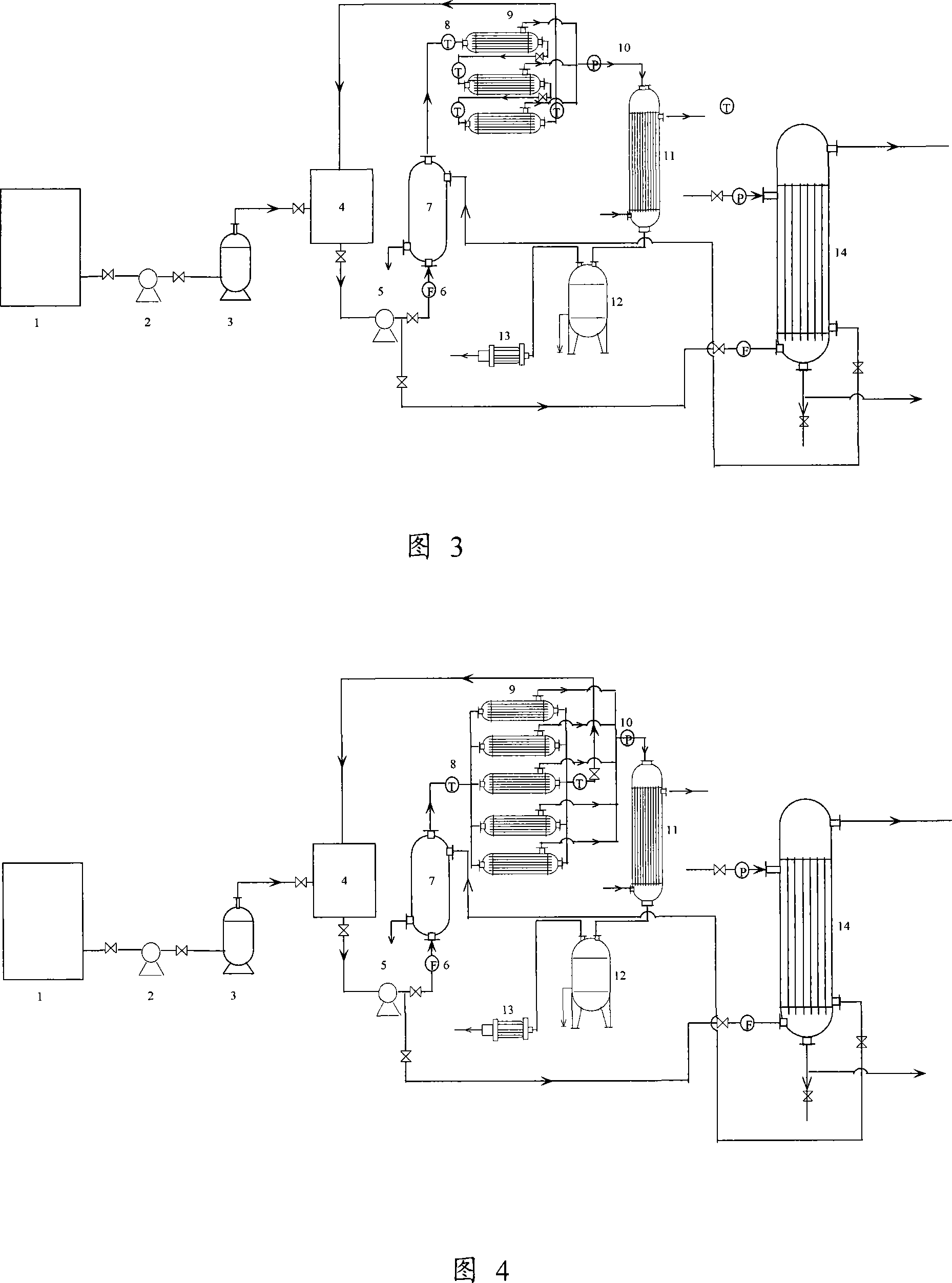

[0046] Referring to Fig. 2, after the high-salt wastewater flows out from the epoxy resin production reactor, the wastewater with a salt concentration higher than 10% is collected in a regulating tank (mainly sodium chloride), and the COD of the wastewater is usually above 10000ppm.

[0047] Since organic substances such as residual bisphenol A, epichlorohydrin, and their derivatives that have not fully reacted in wastewater are soluble in alkaline, the solubility usually decreases in neutral conditions. Using this feature, the wastewater is first adjusted to Neutral, some higher molecular weight macromolecules are precipitated by bubbling or stirring, and the precipitated organic matter is removed through membrane filtration. The wastewater flow rate during membrane filtration is 160L / h, and the vacuum degree of the permeation side is 0.09MPa. The feed temperature is 80°C; the filtered organic matter is incinerated.

[0048] The waste water from which precipitated organic mat...

Embodiment 3

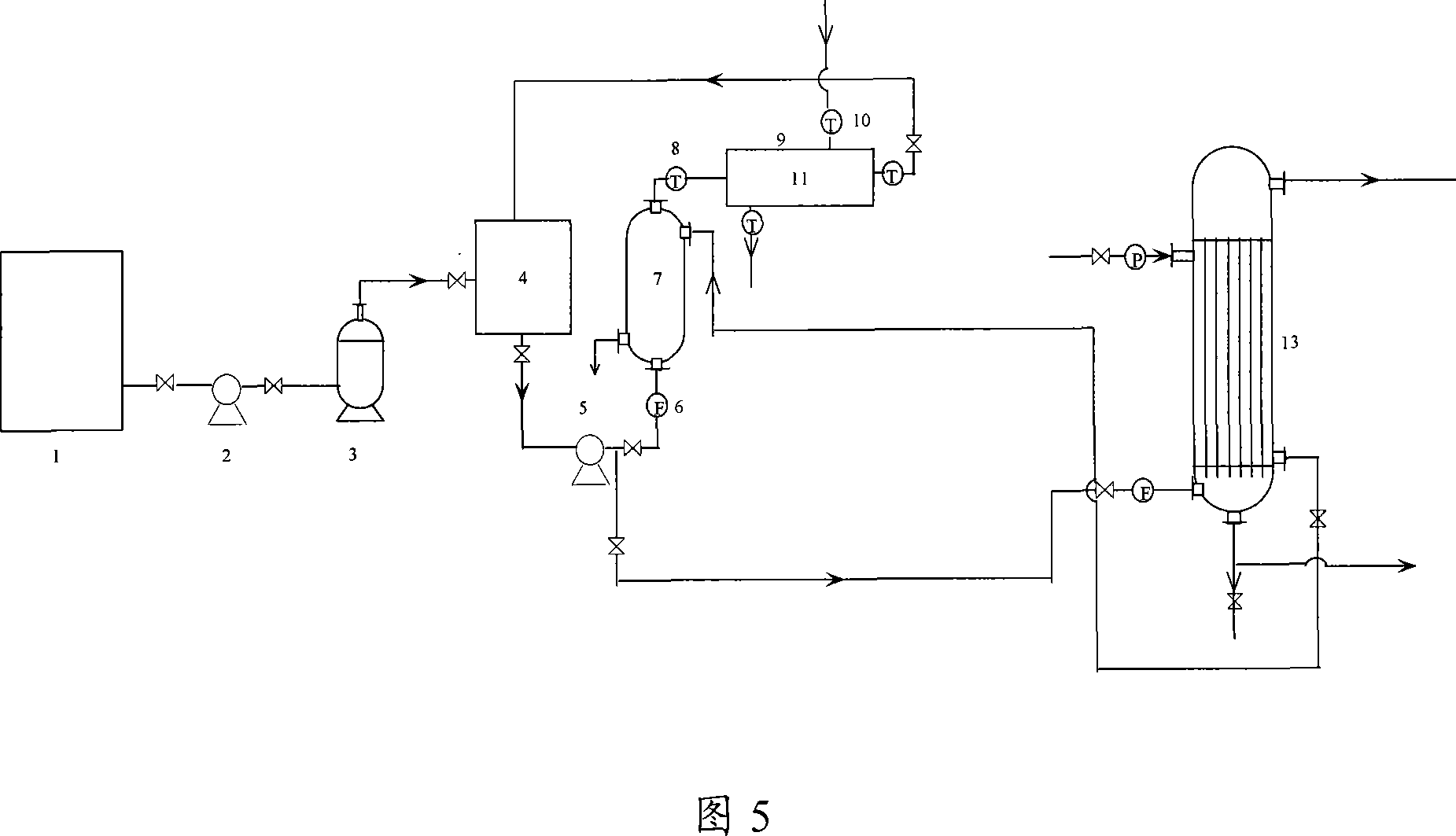

[0057] The wastewater containing organic matter with a salt concentration greater than 10% is adjusted to neutrality by acid, and is filtered through a microporous membrane filter through a booster pump to remove precipitated organic matter in high-salt wastewater. The wastewater flow rate of membrane filtration is generally controlled at 2m 3 / h, depending on the processing capacity of the subsequent membrane distillation device, the wastewater can be heated through the preheating pool, so that the wastewater feed temperature can be controlled within the range of 50-80 °C.

[0058] The evaporation flux of the membrane distillation process is related to the processing capacity of the process. For this reason, the hollow fiber membrane module used for membrane distillation is optimally designed. The ratio of length to diameter (L / D) of the membrane module is 3 ~5, the filling coefficient of the hollow fiber membrane in the module is controlled within the range of 10~40%. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com