Piston positioning type building block production mold

A positioning, block technology, applied in manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve problems such as low processing efficiency, inability to achieve mass production in clusters, and occupation of labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

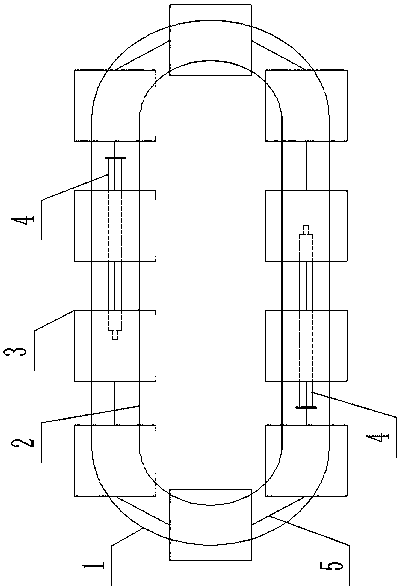

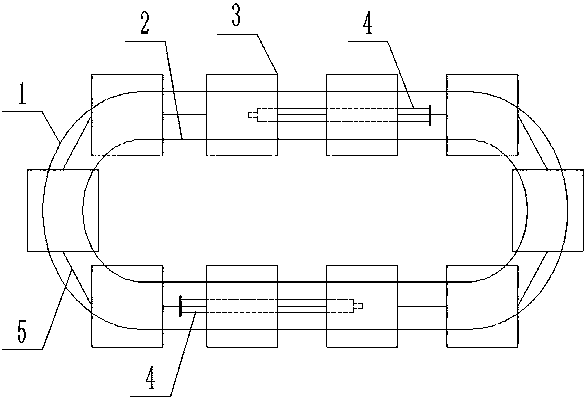

[0011] With reference to the figures covered in the accompanying drawings and specific practical instructions are as follows:

[0012] As shown in the figure, the headstock 7 is installed on the upper part of the bed 1, the spindle servo motor 6 and the feed servo motor 5 are installed on one side of the headstock 7, and the other side is connected with the coupling 8, and the lower part of the coupling 8 A ball screw 9 is arranged, a numerical control system protective cover 2 is installed around the spindle box 7, and the numerical control system 3 is installed on the outside of the numerical control system protective cover 2, and a linear guide rail 14 is arranged on the upper part of the bed 1, and the linear guide rail 14 and the The slide plate 13 is connected and fixed, the upper part of the slide plate 13 is equipped with a spiral winding device 10, the tail end of the bed 1 is equipped with a tailstock 11 through a linear guide rail 14, and the workpiece is clamped by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com