Preparation method and product of hydrophobic PVDF (Polyvinylidene Fluoride) microporous membrane with beta crystalline phase structure

A microporous membrane and hydrophobic technology, applied in the preparation and product field of hydrophobic PVDF microporous membrane with β crystal phase structure, can solve the problems of low membrane flux, high cost, small average pore size, etc., and achieve good application prospects , Low preparation cost, strong hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

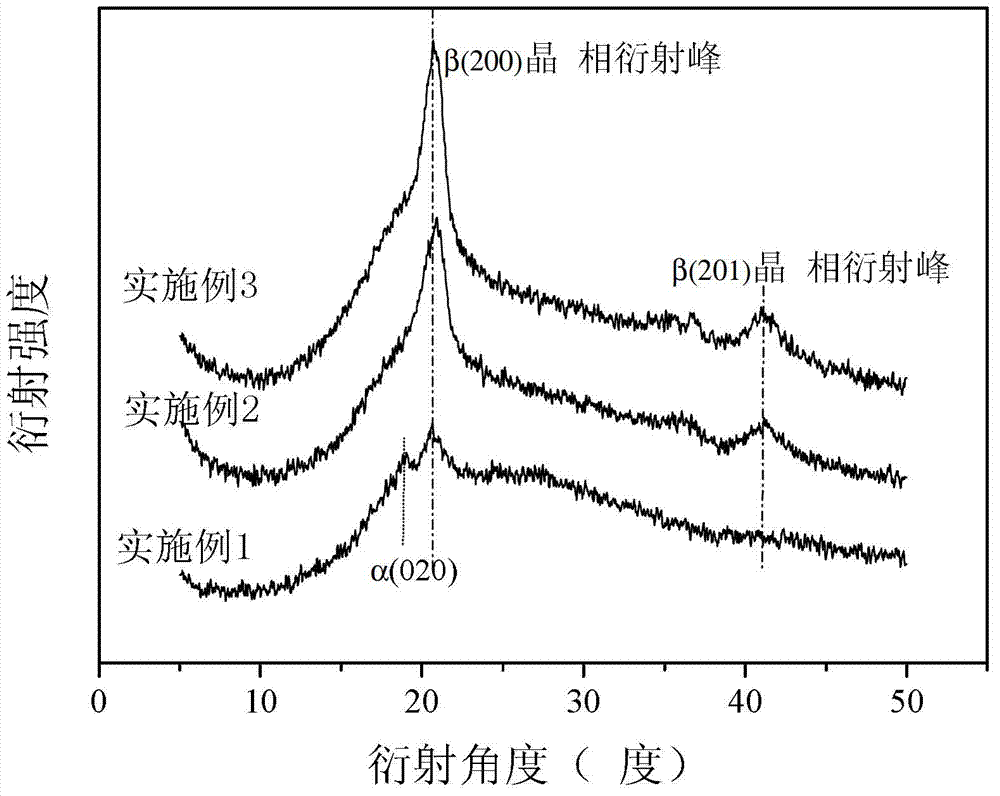

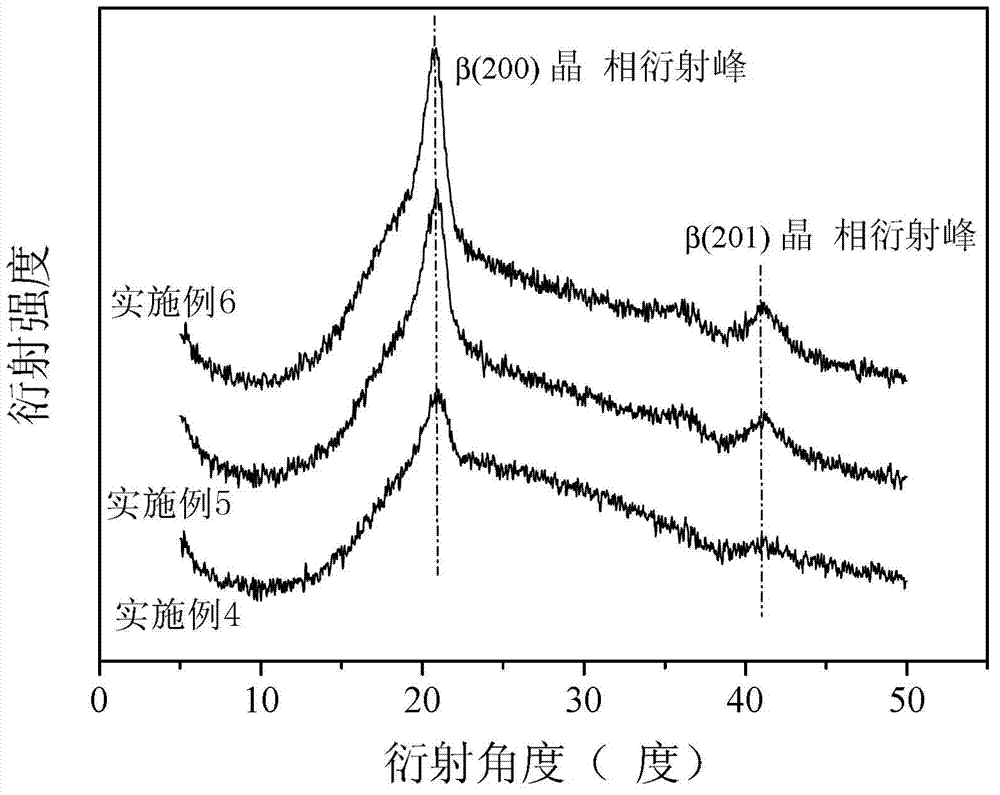

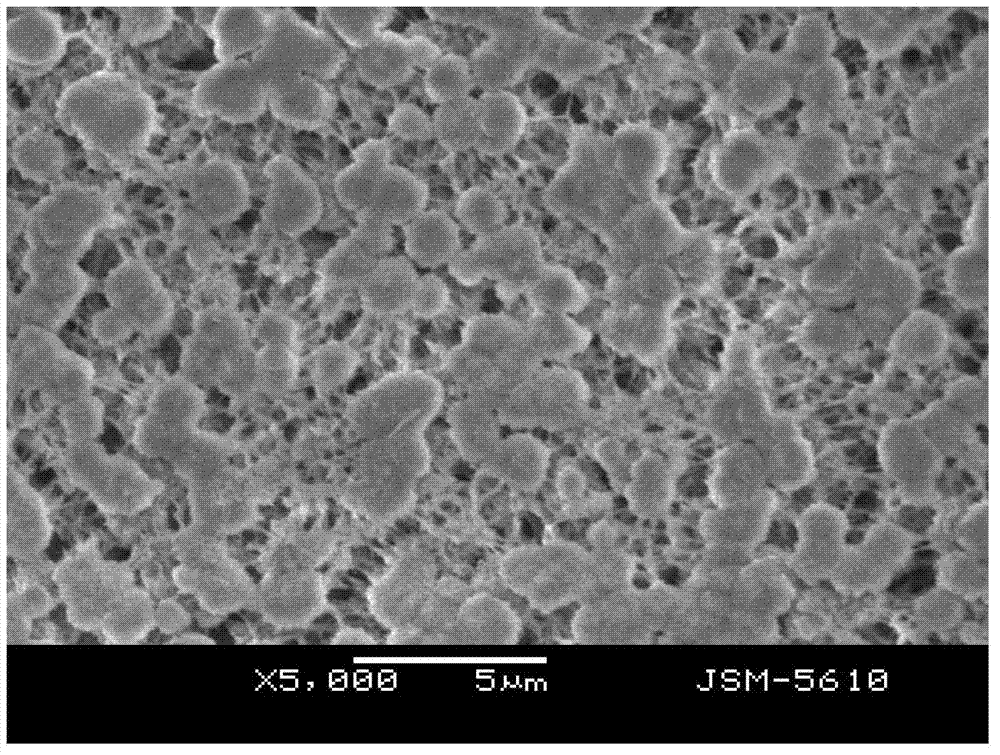

Embodiment 1

[0041] 1. Dissolve 1-butyl-3-methylimidazolium chloride ionic liquid and polyvinylidene fluoride in N-methylpyrrolidone (NMP), then stir at 60°C for 24 hours to prepare a uniform film-forming solution ; In this step, the ratio of raw materials input by mass percentage is: 2% for chlorinated-1-butyl-3-methylimidazolium ionic liquid, 15% for polyvinylidene fluoride, and 83% for N-methylpyrrolidone .

[0042] 2. Degas the film-making solution at 40°C for 18 hours, then use a scraper to scrape a 150 μm nascent flat liquid film on the flat carrier, and stay in the air at a temperature of 20°C and a relative humidity of 40% for 30 seconds ; Immerse the nascent liquid film on the flat carrier in deionized water at 20° C. to solidify to form a film, and the curing time to form a film is 20 seconds.

[0043] 3. Continue soaking in deionized water for 3 days after the membrane is cured, so that the ionic liquid can be completely removed from the membrane.

[0044] The properties of th...

Embodiment 2

[0046] 1. Dissolve 1-hexyl-3-methylimidazolium chloride ionic liquid and polyvinylidene fluoride in N,N-dimethylformamide (DMF), then stir at 65°C for 12 hours to prepare a homogeneous Membrane-making solution; in this step, the ratio of raw materials input by mass percentage is: 2% for chlorinated-1-hexyl-3-methylimidazolium ionic liquid, 15% for polyvinylidene fluoride, 15% for N, N-dimethyl The base formamide is 83%.

[0047] 2. Static defoaming of the film-making solution at 50°C for 20 hours, and then use a scraper to scrape a 200 μm nascent flat liquid film on the flat carrier, and stay in the air at a temperature of 25°C and a relative humidity of 50% for 40 seconds ; The nascent liquid film on the flat carrier is immersed in deionized water at 25° C. to solidify into a film, and the solidification time is 30 seconds.

[0048] 3. Continue soaking in deionized water for 3 days after the membrane is cured, so that the ionic liquid can be completely removed from the membr...

Embodiment 3

[0051] 1. Dissolve 1-octyl-3-methylimidazolium chloride ionic liquid and polyvinylidene fluoride in N,N-dimethylacetamide (DMAc), then stir at 70°C for 12 hours to prepare a homogeneous film-making solution; in this step, the raw material ratio calculated by mass percentage is: chlorinated-1-octyl-3-methylimidazolium ionic liquid is 2%, polyvinylidene fluoride is 15%, N, N- Dimethylacetamide is 83%.

[0052] 2. Degas the film-making solution at 60°C for 24 hours, then use a scraper to scrape a 250 μm nascent flat liquid film on the flat carrier, and stay in the air at a temperature of 30°C and a relative humidity of 60% for 50 seconds ; The nascent liquid film on the flat carrier is immersed in deionized water at 30° C. to solidify into a film, and the solidification time is 30 seconds.

[0053] 3. Continue soaking in deionized water for 3 days after the membrane is cured, so that the ionic liquid can be completely removed from the membrane.

[0054] The properties of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com