Recycling method of high brine waste water based on forward osmosis

A treatment method and high-salt technology, applied in the field of membrane separation, can solve the problems of reduced applicability, singleness and complexity of the membrane distillation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Treatment of shale gas fracturing wastewater by FO-MD coupling process

[0053] Indicators of shale gas fracturing wastewater after pretreatment:

[0054] Analysis Project

unit

indicators

mg / l as CaCO 3 count

210

Cl -

mg / l

56720

SO 4 2-

mg / l

28

Na +

mg / l

29130

K +

mg / l

1263

Ca 2+

mg / l

7830

Mg 2+

mg / l

412

Ba 2+

mg / l

11.3

Sr 2+

mg / l

1182

total hardness

mg / l as CaCO 3 count

46210

TDS

mg / l

152312

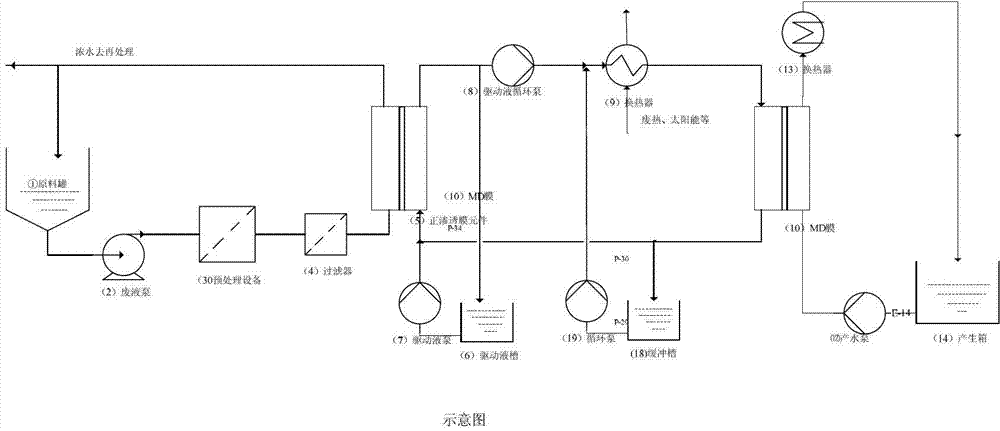

[0055] The process of coupling forward osmosis and membrane distillation is adopted, and the process flow is shown in the schematic diagram figure 1 , the forward osmosis drive solution uses 2.55M MgCl 2 Solution, FO membrane adopts CTA flat membrane, adopts AL-DS mode; membrane distillation adopts DCMD process, MD membrane adopts CF 4 Hydrophobic tre...

Embodiment 2

[0057] Example 2: Treatment of Glyphosate Industrial Wastewater by FO-MD Coupling Process

[0058] Influent water quality indicators after pretreatment are:

[0059] project

indicators

Remark

Glyphosate(g / L)

8.5

After preprocessing

TOC (g / L)

15.4

After preprocessing

NaCl(g / L)

122

After preprocessing

[0060] Na 2 HPO 3 (g / L)

15

After preprocessing

pH

9.5

After preprocessing

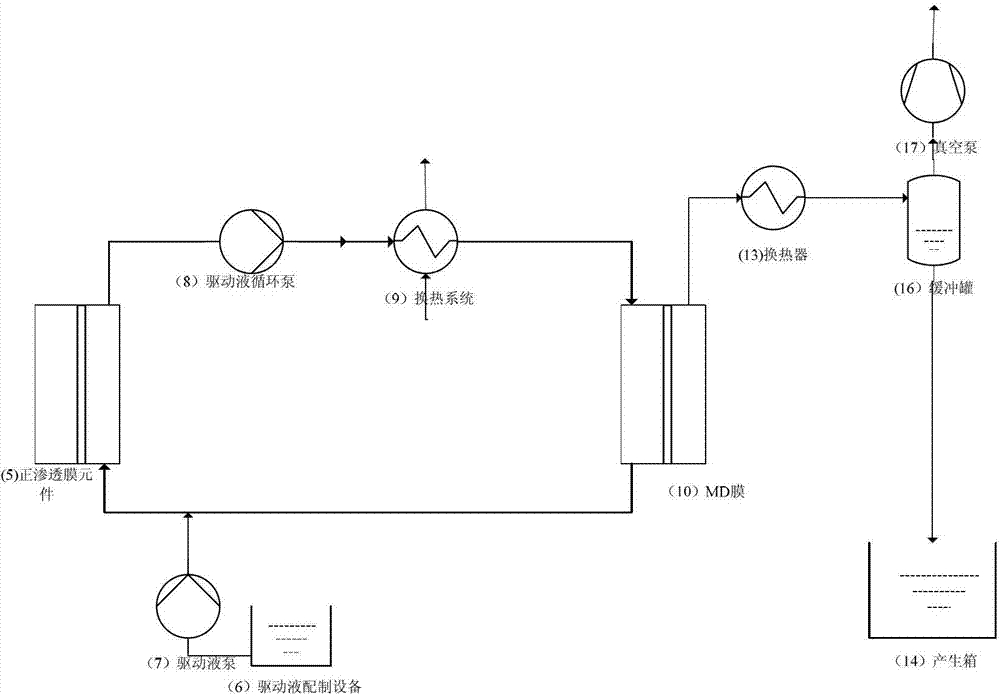

[0061] The forward osmosis-membrane distillation coupling process is used to treat glyphosate wastewater, and the forward osmosis process of glyphosate wastewater is shown in the diagram figure 1 , the process flow of membrane distillation is shown in the schematic diagram figure 2 , the forward osmosis membrane is made of polysulfone material (PSF) surface-treated forward osmosis membrane material, the drive fluid is 23% sodium chloride aqueous solution, and the AL-DS operation mode is ado...

Embodiment 3

[0063] Example 3: FO-MD coupling process for treating silver nitrate wastewater

[0064] The petrochemical industry uses precious metal compounds as catalysts, and recycling the precious metals of spent catalysts is an effective means to reduce costs. The silver catalyst is dissolved in nitric acid and then directly evaporated and concentrated by steam, which not only consumes a lot of steam, but also silver nitrate is extremely unstable, and its decomposition is intensified at high temperature, which requires high equipment. In order to reduce costs, FO-MD coupling process is used for processing.

[0065] The main indicators of silver nitrate wastewater after pretreatment are: silver nitrate content: 3-3.5%; excess nitric acid content: 1-2%, a small amount of other impurities.

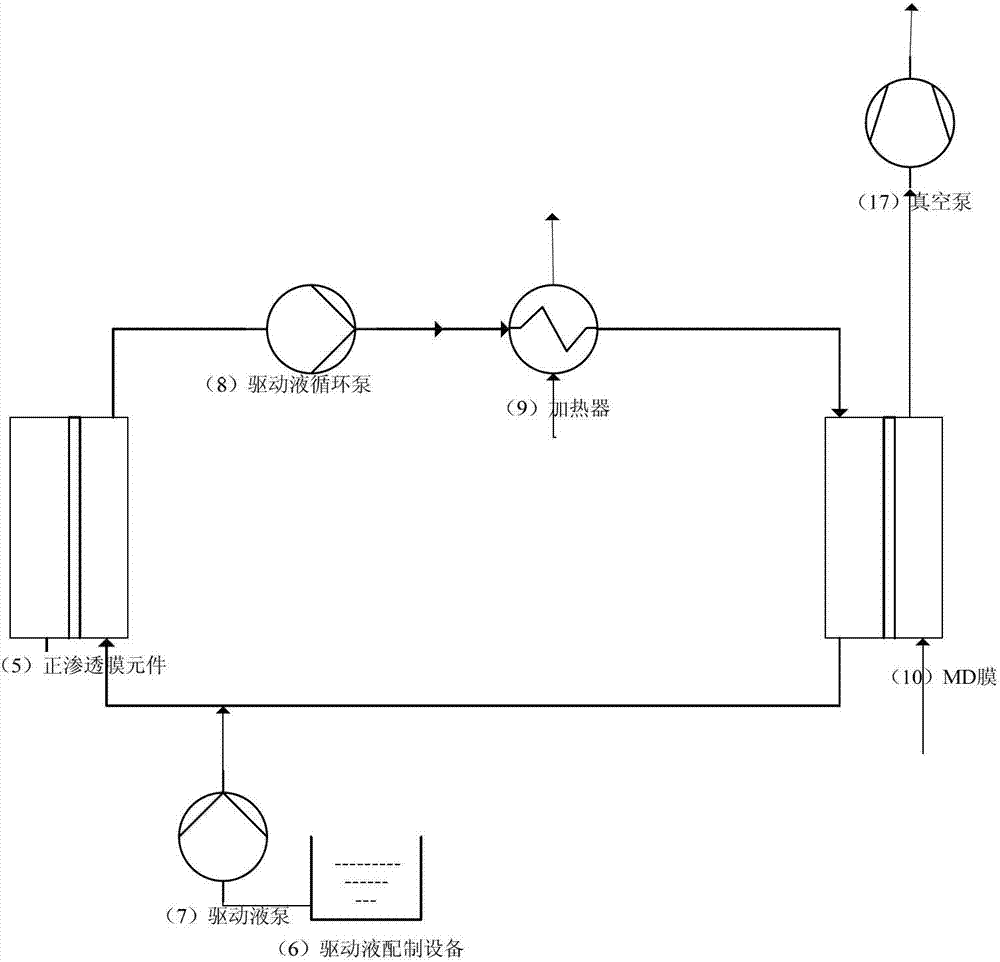

[0066] In the experiment, silver nitrate wastewater was filtered and concentrated by FO-MD coupling process. The FO adopts the FO membrane element produced by HTI Company, the driving fluid adopts 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com