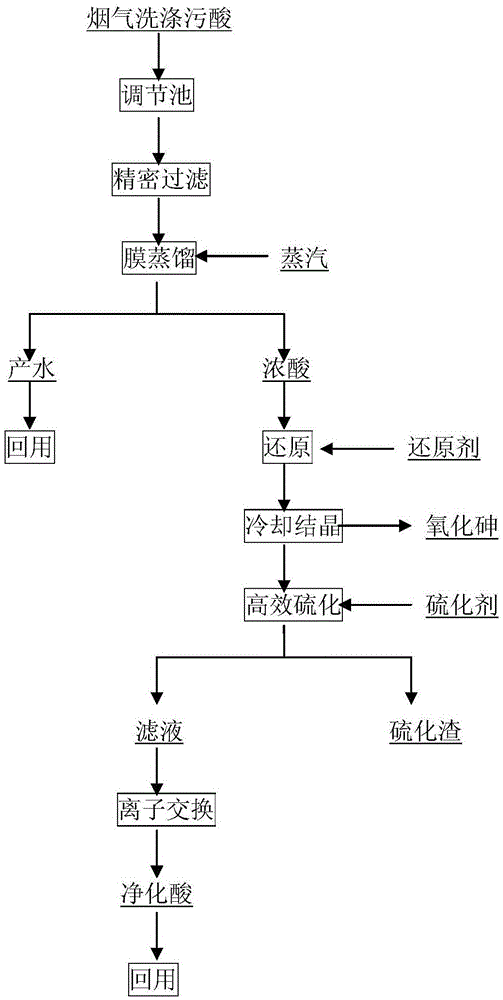

Method for purifying and recycling high arsenic polluted acid wastewater

A technology for wastewater purification and high-arsenic polluted acid, which is applied in chemical instruments and methods, water/sewage treatment, metallurgical wastewater treatment, etc., can solve the problems of increasing the amount of polluted acid treatment, low recovery acidity, unfavorable reuse, etc., to reduce The production of sulfide slag, less impurity content, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

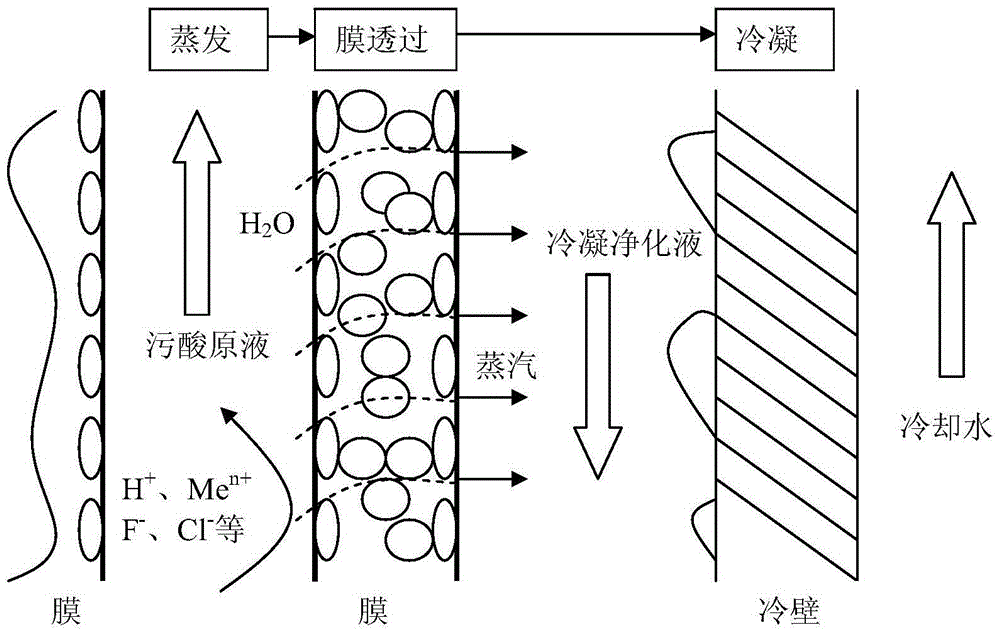

Embodiment 1

[0036] The sewage acid wastewater from a smelting enterprise is homogenized and filtered for particles and colloidal impurities before entering the membrane distillation device. The filter material has a pore size of 10 μm; the filter material is organic porous material PP, and the filter form is a bag filter. Then adopt the hollow fiber tubular membrane module multi-effect membrane distillation method, the membrane material is PVDF, the membrane pore size is 0.3-0.5um, and the flux is 3-5L / m 2 ;Heat the dirty acid with the steam through the PTFE-lined heat exchanger, control the temperature at 80°C, use a water circulation vacuum pump to draw a vacuum, the vacuum degree is -0.08Mpa, the concentration factor is 3.2 times, and the circulating cooling water is used to condense and purify the water. is 25°C. The distilled and concentrated waste acid is reduced by sulfurous acid, and the reducing agent is added according to the ratio of reducing agent to pentavalent arsenic of 1.2...

Embodiment 2

[0039] The sewage acid wastewater from a smelting enterprise is homogenized and filtered for particles and colloidal impurities before entering the membrane distillation device. When filtering, the pore size of the filter material is 5 μm; the filter material is organic porous material PP, and the filter form is a membrane filter. Then, the hollow fiber tubular membrane module multi-effect membrane distillation method is adopted. The membrane material is PTFE, and the membrane pore size is 0.2-0.4um. The acid concentration test is carried out on the polluted acid wastewater, and the steam is passed through the PTFE-lined heat exchanger to heat the polluted acid. The temperature is controlled at 85°C, the plunger vacuum pump is used to draw a vacuum, the vacuum degree is -0.085Mpa, the concentration factor is 3.3 times, and the circulating cooling water is used to condense and purify the water, and the water temperature is 25°C. The distilled and concentrated waste acid is reduc...

Embodiment 3

[0042] The polluted acid wastewater from a smelting enterprise is homogenized and filtered for particles and colloidal impurities before entering the membrane distillation device. The pore size of the filter material is 0.5 μm; the filter material is organic porous material PE, and the filter form is PP cotton filter. Then, the submerged method of hollow fiber tubular membrane module is adopted. The membrane material is PVDF, and the membrane pore size is 0.2-0.4um. The acid concentration test is carried out on the polluted acid wastewater, and the steam is passed through the PTFE-lined heat exchanger to heat the polluted acid. The temperature is 70°C, and the water circulation vacuum pump is used to extract the vacuum, the vacuum degree is -0.075Mpa, the concentration ratio is 3.5 times, and the circulating cooling water is used to condense and purify the water, and the water temperature is 25°C. The distilled and concentrated waste acid is reduced by sulfur dioxide, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com