Desalting method for salted egg white

A technology for desalination and salted eggs, which is applied in food science and other fields, can solve the problems of high energy consumption, high cost, and large amount of acid and alkali, and achieve high safety performance, low equipment requirements, and favorable recycling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

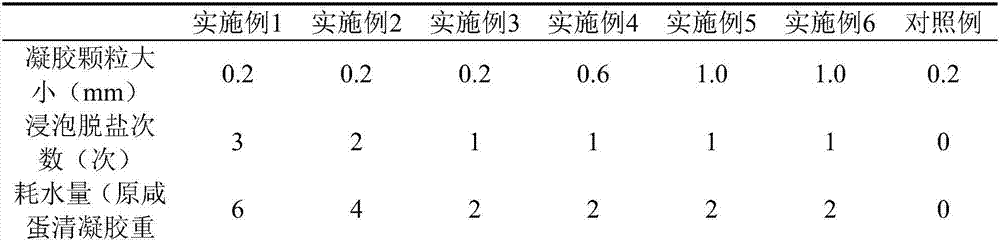

Embodiment 1

[0032](1) The salted egg white is heat-treated at 80°C for 40 minutes to form a gel; the proportion of insoluble protein to the total protein is about 95%.

[0033] (2) Use a blender to crush the salted egg white gel into 0.2mm-sized granules.

[0034] (3) Put the salted egg white gel particles obtained in step (2) into a dehydrator with a filter bag, and first remove part of the moisture and salt in the original gel particles quickly by centrifugation;

[0035] In step (3), the pore diameter of the filter bag is 0.0308mm, and the centrifugal force is 5000g under the condition of centrifugation for 2min. After centrifugation, the salted egg white gel particles remove 30% of water and salt.

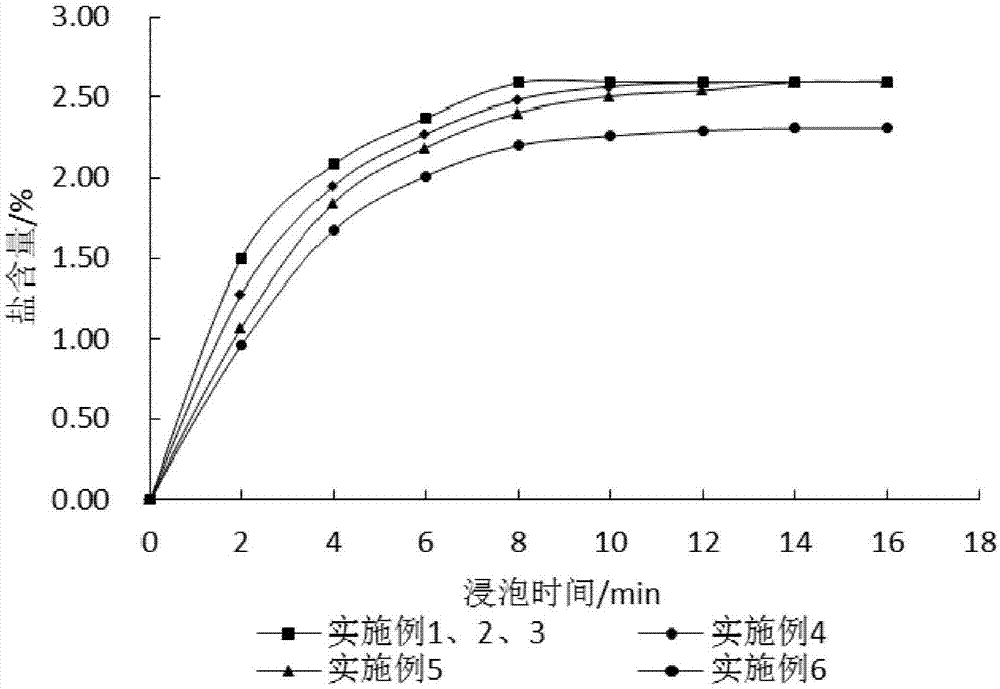

[0036] (4) Soak the dehydrated salted egg white gel particles obtained in step (3) in water, quickly reach the soaking equilibrium, and put them into a dehydrator with a filter bag for centrifugation. Repeat this step twice to obtain desalted salty egg white gel particles. egg white gel p...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is:

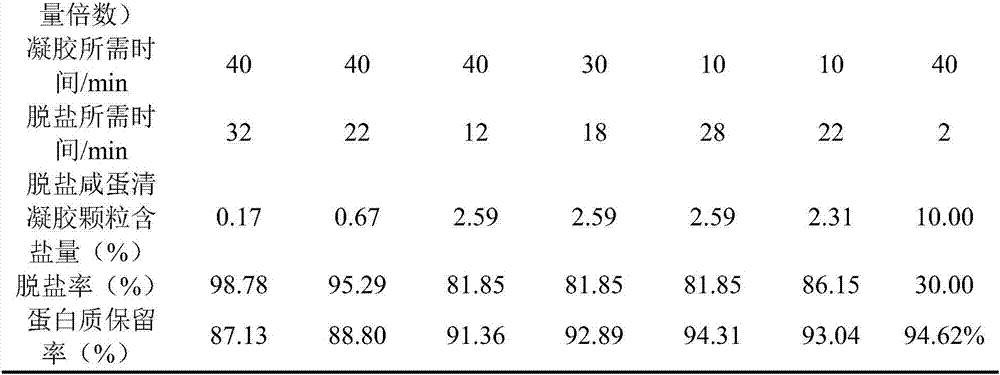

[0042] (4) The number of soaking times is 2 times. The desalted salted egg white gel particles obtained after centrifugation contain a desalination rate of 95.29%, a protein retention rate of 88.80%, and water consumption that is four times the weight of the original salted egg white gel.

[0043] (5) After the obtained desalted salted egg white gel particles are vacuum-packed, pasteurized for 30 minutes and cooled to obtain desalted protein particles, the protein content is 13.32%, the salt content is 0.67%, the color difference value L=88.69, a= -1.43, b=5.13.

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is:

[0046] (4) The number of immersion is 1 time. The desalted salted egg white gel particles obtained after centrifugation contain a desalination rate of 81.85%, a protein retention rate of 91.36%, and water consumption twice the weight of the original salted egg white gel.

[0047] (5) Add water to the desalted salted egg white gel particles and use a mixer to crush them, then use a high-pressure homogenizer to homogenize them so that the particle size reaches 0.2-20 μm, and spray dry them to obtain desalted protein powder with a protein content of 80.03% , the salt content is 15.00%, the color difference value L=89.21, a=1.98, b=5.67.

[0048] (6) The obtained desalted protein powder is directly added to powdery raw materials in a ratio of 5% to 10% for mixed use, and is applied to mayonnaise, biscuits, and cakes. The final salt content brought by the desalted protein powder is ≤1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com