Preparation method and use method of CuS modified immobilized TiO2 nanoribbon photocatalyst

A photocatalyst and nanobelt technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of improving utilization, recycling, and improving contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A CuS-modified immobilized TiO 2 The preparation method of nanobelt photocatalyst is characterized in that, specifically comprises the following steps:

[0029] (1) Pretreatment of the titanium sheet: first, the titanium sheet with a thickness of 0.5 mm is cut into a specification of 90 mm × 40 mm, then, in ethanol and acetone with a purity of 99.5%, it is ultrasonically cleaned at 150 W for 10 min, and Pickling for 30s, the mass ratio of pickling is HF:HNO 3 :H 2 The mixed solution composed of O=1:4:5 was finally rinsed with deionized water and dried in air at 105°C for 1 hour for later use;

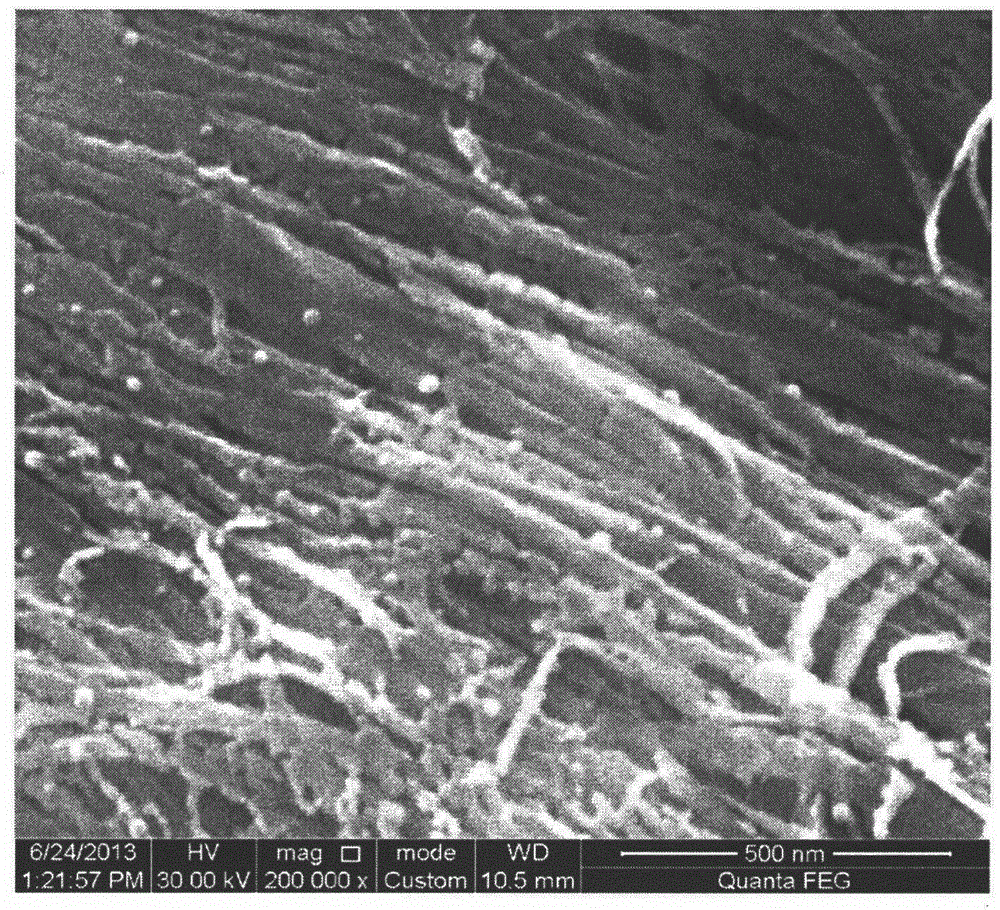

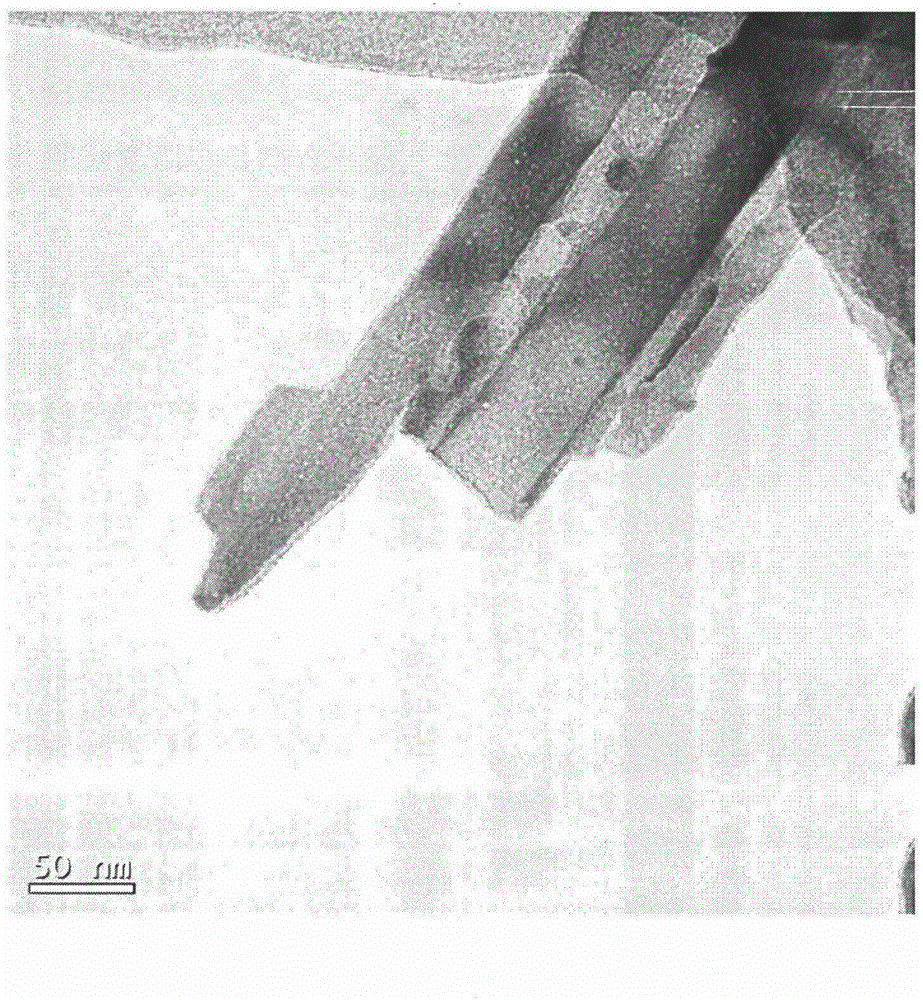

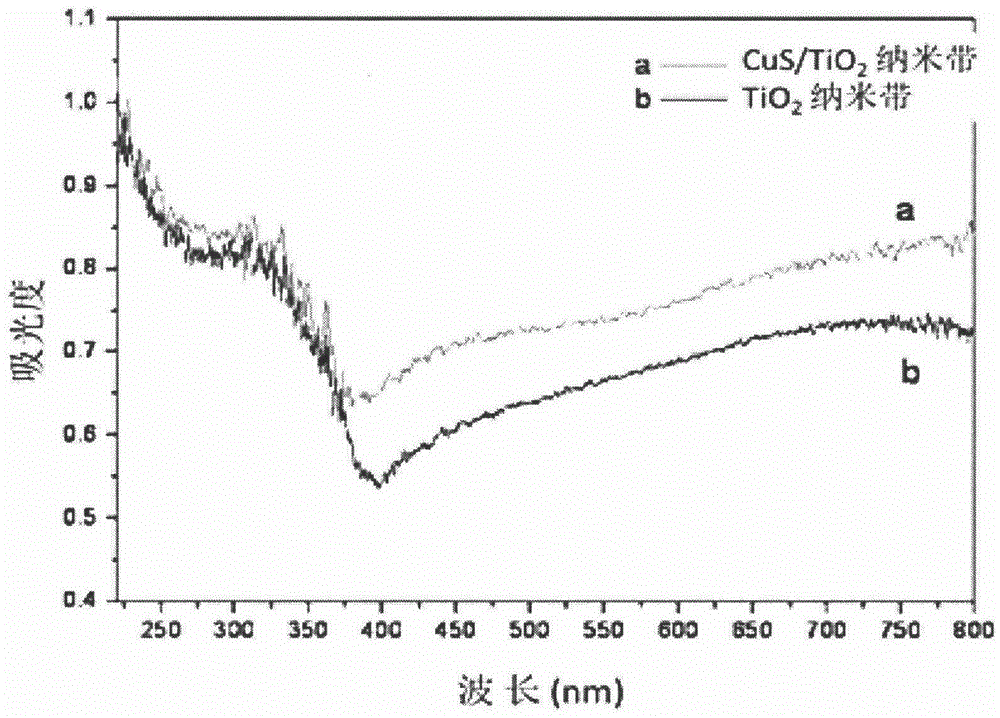

[0030] (2) Immobilized TiO 2 Preparation of nanoribbon: carry out electrochemical anodic oxidation treatment to titanium sheet, with titanium sheet as anode, platinum sheet as cathode, electrolyte is ethylene glycol, contains 5vol% water and 0.5wt% ammonium fluoride in the electrolyte, keeps The voltage is 60 constant voltage, the temperature is 25°C constant temperature, the...

Embodiment 2

[0034] A CuS-modified immobilized TiO 2 The preparation method of nanobelt photocatalyst is characterized in that, specifically comprises the following steps:

[0035] (1) Pretreatment of the titanium sheet: first, the titanium sheet with a thickness of 0.5 mm is cut into a specification of 90 mm × 40 mm, then, in ethanol and acetone with a purity of 99.5%, it is ultrasonically cleaned at 150 W for 10 min, and Pickling for 30s, the mass ratio of pickling is HF:HNO 3 :H 2 The mixed solution composed of O=1:4:5 was finally rinsed with deionized water and dried in air at 105°C for 1 hour for later use;

[0036] (2) Immobilized TiO 2 Preparation of nanoribbon: carry out electrochemical anodic oxidation treatment to titanium sheet, with titanium sheet as anode, platinum sheet as cathode, electrolyte is ethylene glycol, contains 5vol% water and 0.5wt% ammonium fluoride in the electrolyte, keeps The voltage is 70V constant voltage, the temperature is 25°C constant temperature, th...

Embodiment 3

[0040] A CuS-modified immobilized TiO 2 The preparation method of nanobelt photocatalyst is characterized in that, specifically comprises the following steps:

[0041] (1) Pretreatment of the titanium sheet: first, the titanium sheet with a thickness of 0.5 mm is cut into a specification of 90 mm × 40 mm, then, in ethanol and acetone with a purity of 99.5%, it is ultrasonically cleaned at 150 W for 10 min, and Pickling for 30s, the mass ratio of pickling is HF:HNO 3 :H 2 The mixed solution composed of O=1:4:5 was finally rinsed with deionized water and dried in air at 105°C for 1 hour for later use;

[0042] (2) Immobilized TiO 2 Preparation of nanoribbon: carry out electrochemical anodic oxidation treatment to titanium sheet, with titanium sheet as anode, platinum sheet as cathode, electrolyte is ethylene glycol, contains 5vol% water and 0.5wt% ammonium fluoride in the electrolyte, keeps The voltage is 80V constant voltage, the temperature is 25°C constant temperature, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com