Preparation method of waste tire rubber/polyethylene foam material

A waste tire rubber and polyethylene foaming technology is applied in the field of preparation of polymer blend materials, which can solve the problems of lack of competitive advantages, easy deformation of products, poor physical properties, etc., and improve interface interaction and compatibility. , the preparation process is simple, the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

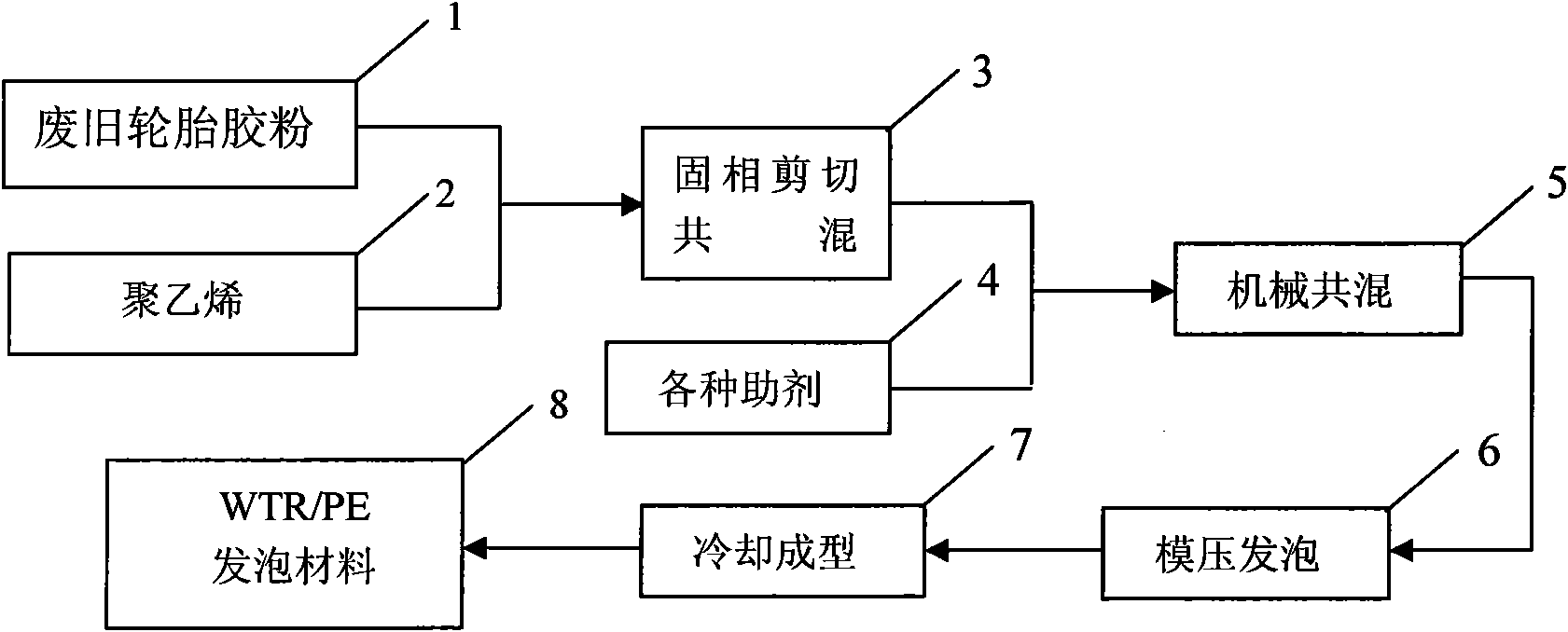

Method used

Image

Examples

Embodiment 1

[0045] (1) Drying of waste tire rubber powder

[0046] Spread a thin layer of waste tire rubber powder with an average particle size of 100 μm in a blast oven, and dry it at 100°C for 0.5h;

[0047] (2) Solid phase mixing

[0048]Add 20 parts of dried waste tire rubber powder and 100 parts of recycled low-density polyethylene pellets into a mechanochemical reactor for solid-phase blending and shearing. The static pressure of the two grinding discs is controlled at 12000kN, and the rotation speed is 150rpm. After the milling cycle, a uniformly mixed powdery compound is formed, which is ready for use;

[0049] (3) Thermoplastic processing

[0050] Put the uniformly mixed above-mentioned materials together with 1 part of sodium bicarbonate, 1 part of antioxidant 1010, 2 parts of dicumyl peroxide, 2 parts of zinc oxide and 1 part of zinc stearate into a Brabender plastifier. Melt blending, mixing temperature 150°C, rotor speed 30rpm, time 6min;

[0051] (4) Molded foam

[005...

Embodiment 2

[0054] (1) Drying of waste tire rubber powder

[0055] Spread a thin layer of waste tire rubber powder with an average particle size of 180 μm in a blast oven and dry at 60°C for 2 hours;

[0056] (2) Solid phase mixing

[0057] Add 30 parts of dried waste tire rubber powder and 100 parts of high-density polyethylene pellets into a mechanochemical reactor for solid-phase blending and shearing. The static pressure of the two grinding discs is controlled at 18000 kN, and the rotation speed is 80 rpm. After the grinding cycle, a uniformly mixed powder compound is formed, which is ready for use;

[0058] (3) Thermoplastic processing

[0059] Mix the above materials uniformly with 2 parts of calcium bicarbonate, 10102 parts of antioxidant, 1 part of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 1 part of zinc oxide and hard 1 part of calcium fatty acid was added to a Brabender plasticizer for melt blending, the mixing temperature was 120°C, the rotor speed was 50 rpm, and the mi...

Embodiment 3

[0063] (1) Drying of waste tire rubber powder

[0064] Spread a thin layer of waste tire rubber powder with an average particle size of 250 μm in a blast oven and dry at 80°C for 1 hour;

[0065] (2) Solid phase mixing

[0066] Add 40 parts of dried waste tire rubber powder and 100 parts of low-density polyethylene pellets into a mechanochemical reactor for solid-phase blending and shearing. The static pressure of the two grinding discs is controlled at 22000kN, and the rotation speed is 30rpm. After the grinding cycle, a uniformly mixed powder compound is formed, which is ready for use;

[0067] (3) Thermoplastic processing

[0068] Add the uniformly mixed above-mentioned materials, 5 parts of azodicarbonamide, 2 parts of dicumyl peroxide, 4 parts of zinc oxide, 1.5 parts of stearic acid, and 10102 parts of antioxidant into a Brabender plastifier. Melt blending, mixing temperature 135°C, rotor speed 50rpm, time 10min;

[0069] (4) Molded foam

[0070] Put 15 parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com